A processing method of mercerized fiber and fiber liquid ammonia mercerized and its application in size-free woven fabrics

A processing method and liquid ammonia mercerization technology, which is applied in the mercerizing, weaving, and fabric directions of yarn/thread/filament to achieve the effects of less hairiness, environmental protection, and enhanced dye penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

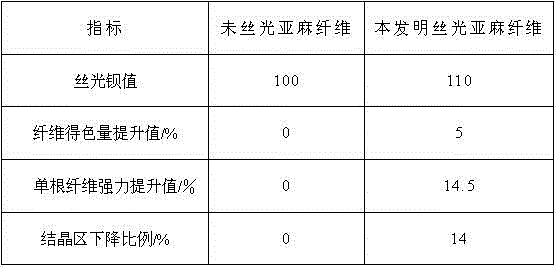

Image

Examples

Embodiment 1

[0034] A kind of warp yarn is 60S / 2 mercerized cotton thread, and weft yarn is 60S / 2 mercerized cotton thread and the processing method of size-free woven fabric is as follows:

[0035] 1. Fiber sliver making: The long-staple cotton is blended, cleaned, carded, slivered and rolled, and combed into fiber sliver.

[0036] 2. Weaving into rope braids: Weave 3 untwisted fiber strips into three-strand braids or ponytail braids according to certain rules, which are used for mercerizing in the subsequent process.

[0037] 3. Pre-drying: reduce the liquid-carrying rate of the treated fiber, so that the liquid-carrying rate of the fiber entering the liquid ammonia immersion tank is 3%.

[0038] 4. Liquid ammonia mercerizing: the temperature of liquid ammonia in liquid ammonia mercerizing is -33.5 ℃, the soaking time is 15 minutes, the temperature of the squeeze liquid ammonia treatment room is 60 ℃, the tensile tension is 10kg, and the pressure of the dipping roll is 1 kg.

[0039] 5....

Embodiment 2

[0049]A kind of warp yarn is 80S / 2 mercerized cotton / tencel (75 / 25) single yarn, and the weft yarn is 80S / 2 fine cotton, and the processing method of the size-free woven fabric is as follows:

[0050] 1. Fiber sliver making: Cotton and Tencel are blended, cleaned, carded, slivered and rolled, and combed into fiber sliver.

[0051] 2. Weaving into rope braids: Weave 3 untwisted fiber strips into three-strand braids or ponytail braids according to certain rules, which are used for mercerizing in the subsequent process.

[0052] 3. Pre-drying: reduce the liquid-carrying rate of the treated fiber, so that the liquid-carrying rate of the fiber entering the liquid ammonia immersion tank is 1%.

[0053] 4. Liquid ammonia mercerizing: the temperature of liquid ammonia in liquid ammonia mercerizing is -35°C, the soaking time is 30 minutes, the temperature of the liquid ammonia treatment chamber is 80°C, the tensile tension is 6kg, and the pressure of the dipping roller is 2kg.

[0054...

Embodiment 3

[0064] A kind of warp yarn 28S / 2 mercerized cotton, the weft yarn is the processing method of 21D polyester elastic yarn size-free woven fabric as follows:

[0065] 1. Fiber sliver making: Cotton is blended, cleaned, carded, slivered and rolled, and combed into fiber sliver.

[0066] 2. Weaving into rope braids: Weave 4 untwisted fiber strips into four-strand braids or braided cables according to certain rules, which are used for mercerizing in the subsequent process.

[0067] 3. Pre-drying: reduce the liquid-carrying rate of the treated fiber, so that the liquid-carrying rate of the fiber entering the liquid ammonia immersion tank is 1.5%.

[0068] 4. Liquid ammonia mercerizing: the temperature of liquid ammonia in liquid ammonia mercerizing is -36°C, the soaking time is 3 minutes, the temperature of the liquid ammonia treatment chamber is 90°C, the tensile tension is 5kg, and the pressure of the squeeze roller is 1.5 kg.

[0069] 5. Drying and steaming: Dry the rope-like fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com