Crystal cotton three mercerized fabric and processing method thereof

A technology of mercerized fabrics and processing methods, which is applied in the mercerization of indefinite length fabrics, the mercerization of yarn/thread/filament, textiles and papermaking, etc. Weaving, different degrees of mercerization, etc., to achieve the effect of superior dimensional stability, ensuring uniform dyeing, and sufficient mercerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

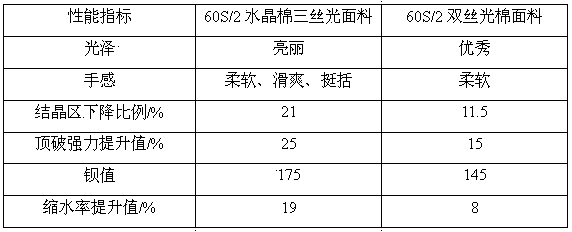

[0062] A 60S / 2 crystal cotton three-mercerized fabric and a processing method thereof, comprising the following processing steps:

[0063] 1. Fiber mercerizing: Weave 4 untwisted Egyptian long-staple cotton slivers into 4 strands of braided cables, and carry out mercerizing in 35 Baume degree liquid alkali. The hot water washing time is 40s, the room temperature water washing time is 20s, the alkali soaking time is 120s, the tensile length is 6%, and decomposed into 4 cotton fiber strips.

[0064] 2. Spinning: mercerized fiber is drawn, roving, spun and twisted to produce 60S / 2 mercerized yarn.

[0065] 3. Singeing: the yarn passes through the burner at 1050°C at a speed of 875m / min, and the hair on the surface is burned off.

[0066] 4. Shaking yarn: Singeing yarn is shaken into 800g / skeined yarn for mercerizing.

[0067] 5. Yarn mercerizing: Carry out mercerizing processing on the skein mercerizing machine, wherein the alkali concentration is 28 degrees Baume, the reaction...

Embodiment 2

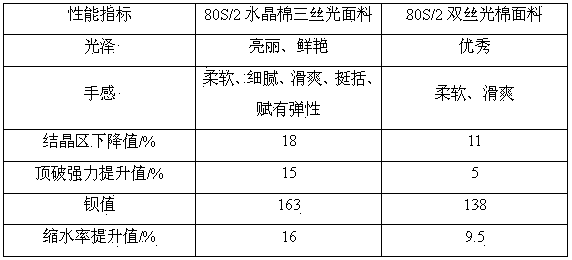

[0080] An 80S / 2 crystal cotton three-mercerized fabric and a processing method thereof, comprising the following processing steps:

[0081] 1. Fiber mercerizing: Weave 3 untwisted Egyptian long-staple cotton slivers into 3 ponytails, and carry out mercerizing in 15 Baume degree of liquid alkali, wherein the temperature of alkali solution is 25°C, and the temperature of hot water washing is 80°C. ℃, hot water washing time is 60s, room temperature washing time is 30s, stretching length is 4%, alkali soaking time is 150s, and decomposed into 3 cotton fiber strips.

[0082] 2. Spinning: 80S / 2 mercerized yarn is obtained by drawing, roving, spun and twisting the mercerized fiber.

[0083] 3. Singeing: the yarn passes through the burner at 1000°C at a speed of 1000m / min, and the hair on the surface is burned off.

[0084] 4. Shaking yarn: shaking and twisting singeing yarn into 650g / skeined yarn for mercerizing.

[0085] 5. Yarn mercerizing: Carry out mercerizing processing on the...

Embodiment 3

[0098] A kind of 70S / 2 bamboo fiber crystal cotton triple mercerized fabric and its processing method, comprising the following processing steps:

[0099] 1. Fiber mercerizing: Weave 4 untwisted bamboo fiber strips into 4 strands of braided cables, and carry out mercerizing in liquid ammonia. The temperature of liquid ammonia is -33.5°C. The tension is 8kg, the vehicle speed is 20m / min, and it is decomposed into 4 bamboo fiber strips.

[0100] 2. Spinning: The mercerized bamboo fiber is drawn, roved, spun and twisted to obtain 70S / 2 mercerized bamboo yarn.

[0101] 3. Singeing: The yarn passes through the burner at 1100°C at a speed of 950m / min to burn off the fine hair on the surface.

[0102] 4. Shaking yarn: shaking and twisting singeing yarn into 550g / skeined yarn for mercerizing.

[0103] 5. Yarn mercerizing: Carry out mercerizing processing on the skein mercerizing machine, wherein the alkali concentration is 15 degrees Baume, the reaction time is 6 minutes, the stretc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com