Gas-tight special threaded fittings for low pressure

A special thread and threaded joint technology, applied in drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of shackle operation and slow make-up, unable to meet the economic and effective development of gas fields, etc., and achieve fast make-up and fast make-up. Easy make-up, make-up and shackle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

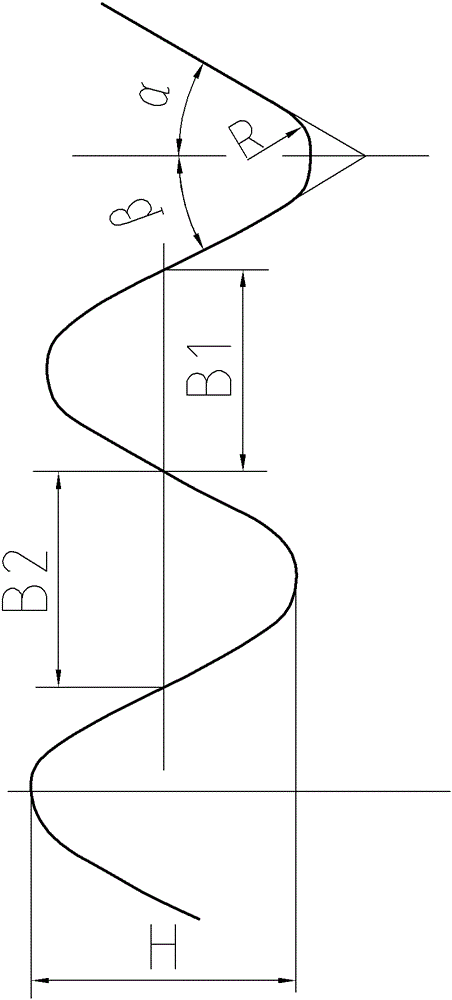

[0027] see figure 1 , a special threaded joint for low-pressure air-tightness according to Embodiment 1 of the present invention, said threaded joint is an externally threaded joint, the angle of bearing surface of said externally threaded joint is α=3°~30°, and the angle of guide surface β= 30°~45°, tooth top arc radius R=0.38mm~0.42mm, alveolar width B1=1.3mm~1.5mm, tooth ridge width B2=1.6mm~1.8mm, tooth height H=1.9mm~2.2mm , The pitch N is 6 to 8 teeth per inch.

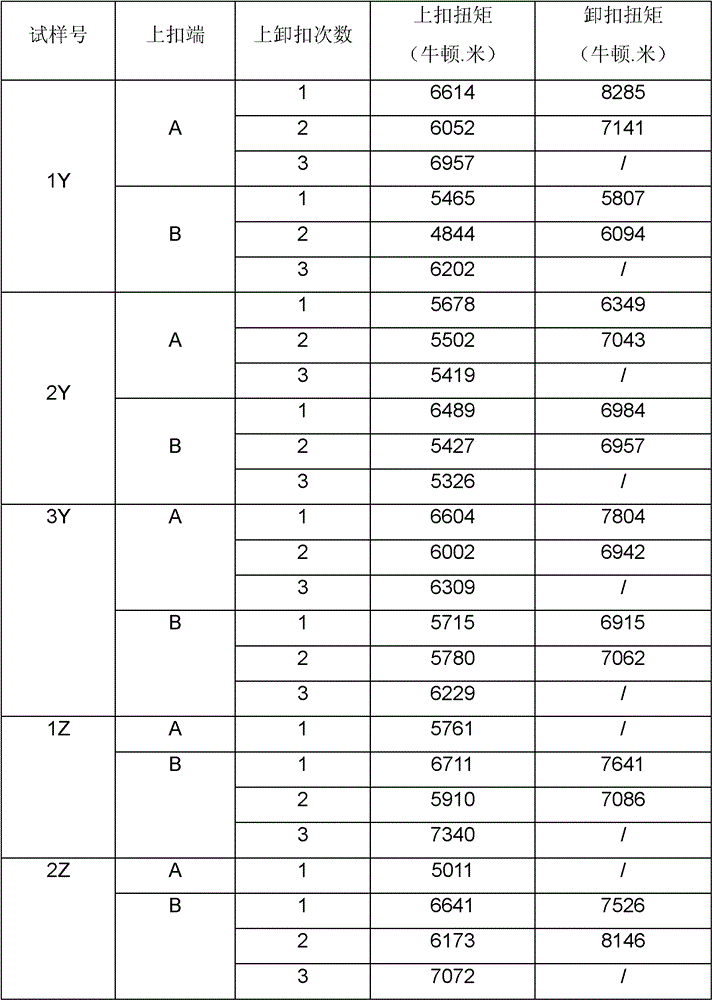

[0028] During specific implementation, the special threaded casing of different specifications can be selected according to the requirements of specific working conditions. The same processing technology as API thread is used in manufacturing. Among them, the coupling and the pipe body are of the same steel grade or a higher steel grade. When making up, both ends are evenly coated with API thread grease, and the middle part of the coupling is clamped. The factory side is made up with the maximum torque, and th...

Embodiment 2

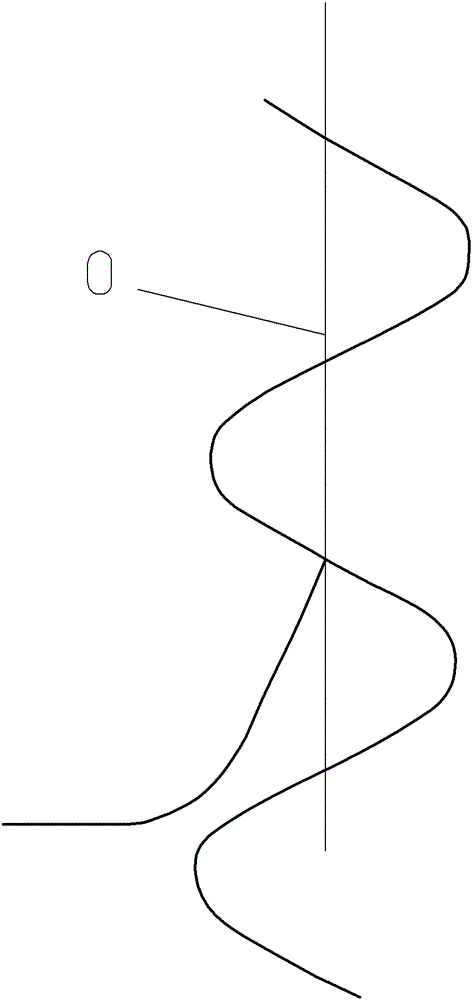

[0032] see figure 1 , a special threaded joint for low pressure air-tightness according to Embodiment 2 of the present invention, the threaded joint is an internal threaded joint, the bearing surface angle of the internal threaded joint is α=3°~30°, and the guide surface angle β= 30°~45°, tooth bottom arc radius R=0.38mm~0.42mm, alveolar width B1=1.3mm~1.5mm, tooth ridge width B2=1.6mm~1.8mm, tooth height H=1.9mm~2.2mm , the pitch N is 6 teeth per inch to 8 teeth per inch, see figure 2 , The internal thread variable taper O is 67mm / m~73mm / m.

[0033] During specific implementation, the special threaded casing of different specifications can be selected according to the requirements of specific working conditions. The same processing technology as API thread is used in manufacturing. Among them, the coupling and the pipe body are of the same steel grade or a higher steel grade, the phosphating thickness of the internal thread is ≥ 20um, API thread grease is evenly applied t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com