Rotational speed control method for pilot injection type numerical control air-powered engine

A pneumatic engine, speed control technology, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of inconvenient operation of the speed control device, and achieve the effect of enhancing practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

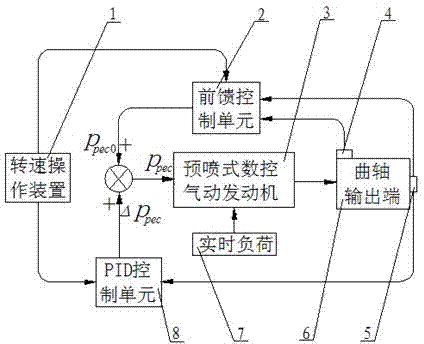

[0021] Such as figure 1 As shown, the torque sensor 4 and the rotational speed sensor 5 are fixedly installed on the crankshaft output end 6 of the pre-injection numerically controlled air motor 3, the rotational speed sensor 5 is connected to the feedforward control unit 2 and the PID control unit 8, and the torque sensor 4 is connected to the feedforward control unit 2.

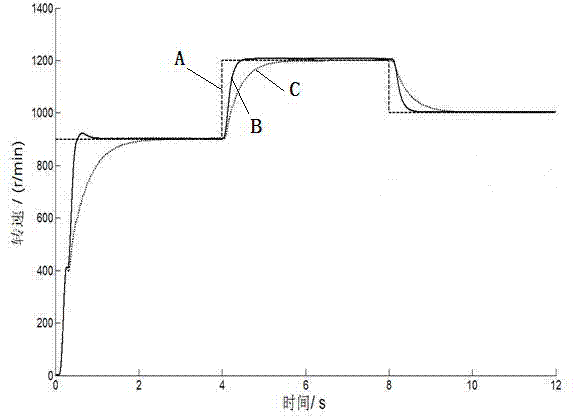

[0022] The pre-injection numerical control pneumatic engine 3 is affected by the real-time load 7, which causes the change of the output end 6 of the crankshaft, and the torque sensor 4 will measure the torque value of the output end 6 of the crankshaft M p Input to the feed-forward control unit 2 through the signal line, and the speed sensor 5 will output the real-time speed of the crankshaft output 6 n r (unit: rev / min) are respectively input to the feed-forward control unit 2 and the PID control unit 8. In order to eliminate the fluctuation of the rotational speed, the real-time rotational speed inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com