Microchannel evaporator and air conditioner with microchannel evaporator

An evaporator and micro-channel technology, applied in evaporators/condensers, refrigeration components, refrigerators, etc., can solve problems such as uneven distribution of refrigerant flow, and achieve improved uneven distribution of refrigerant, optimized length, and optimized distribution Effect of Hole Spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Unless otherwise specified, the terms used in the context of the present invention have the meanings given below. Other terms not specifically given herein have their usual meanings in the art.

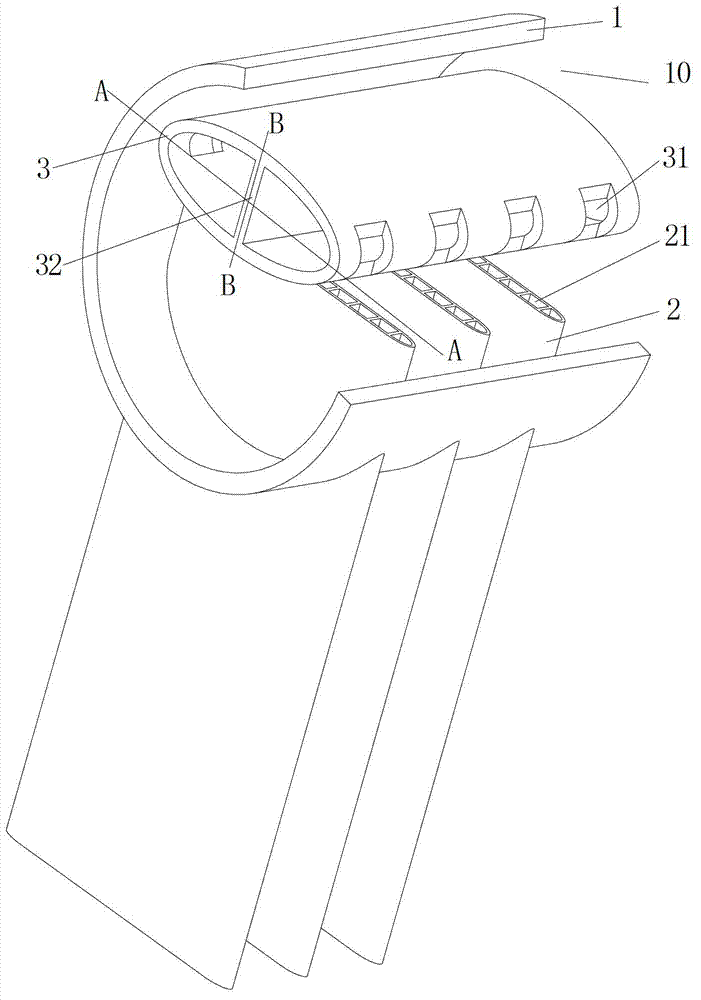

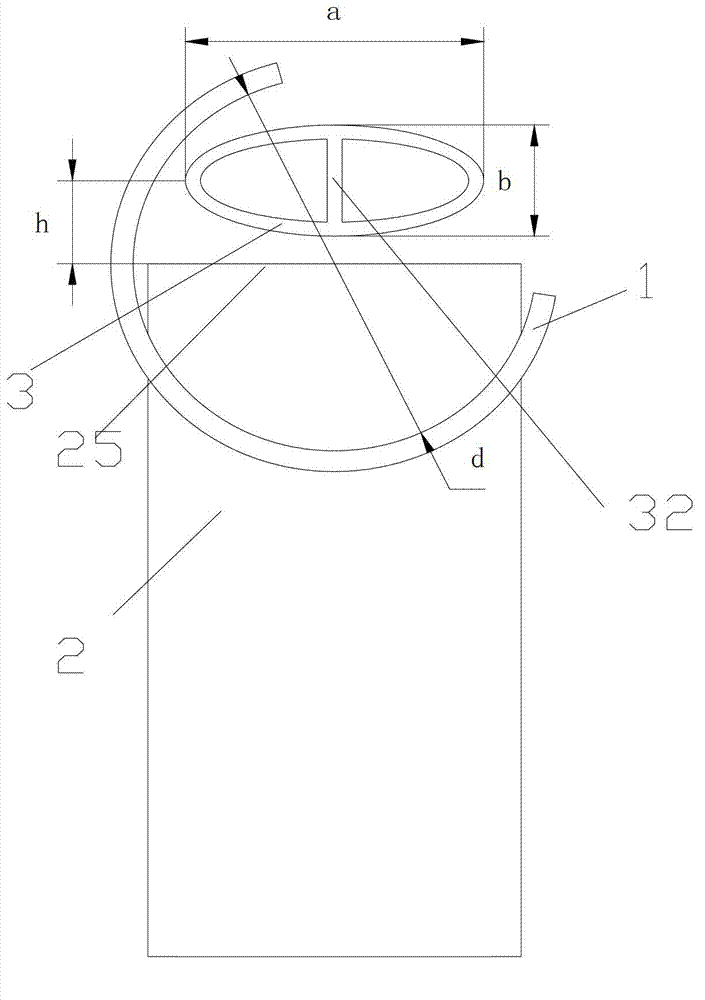

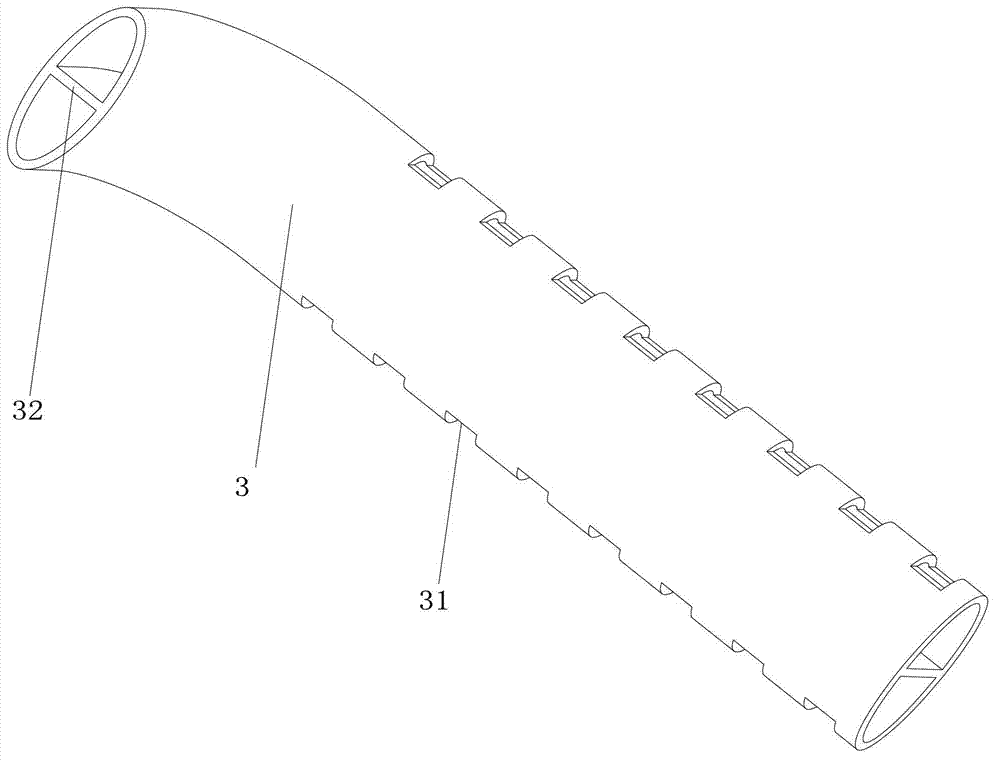

[0024] Such as figure 1 , figure 2 and image 3 , the microchannel evaporator according to the embodiment of the present invention includes a distribution pipe 3, and the distribution pipe 3 is a flat tube, such as a linear flat tube, such as Figure 4 As shown, the distribution pipe 3 can be, for example, L-shaped when viewed from the top view, so as to meet the needs of the internal structure and heat exchange efficiency of the micro-channel evaporator. Since the height of the flat tube-shaped distribution pipe is significantly reduced, the height of the refrigerant in the distribution pipe is correspondingly reduced, and the refrigerant is not prone to stratified flow in the distribution pipe, or the degree of stratified flow is significantly reduced. distribution is mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com