Axle box hole measuring device and its application method

An axle-holding box and hole-measuring technology, which is applied to measurement devices, mechanical measurement devices, and mechanical devices, can solve the problems of low efficiency and high hole cost, and achieve the effects of simple production, improved efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

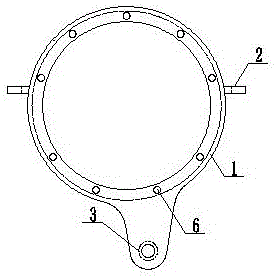

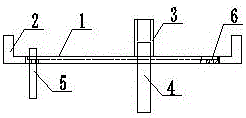

[0019] Such as figure 1 Is a schematic diagram of the structure of the present invention, figure 2 It is a top view of the present invention. A hole measuring device for the axle holding box includes a gauge board 1, a main inspection shaft 4 and a secondary inspection shaft 5. The gauge board 1 is provided with a shaft sleeve 3 and a shaft hole 6, and the main inspection shaft 4 The auxiliary inspection shaft 5 is inserted into the shaft sleeve 3 and the shaft hole 6 respectively. The gauge board 1 is a ring with a mop. The shaft sleeve 3 is vertically welded to the mop of the gauge board 1. The shaft hole 6 is uniformly distributed around the circumference of the gauge board 1. A positioning block 2 is welded symmetrically on both sides of the gauge board 1.

[0020] A method of using the axle box hole measuring device, according to the actual size of the parts to make the axle box hole measuring device, the axle sleeve 3 and the axle hole 6 on the axle box hole measuring d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com