Position detection system with auxiliary cylinder

A detection system and auxiliary cylinder technology, applied in measurement devices, electrical devices, instruments, etc., can solve the problems of sensor service life, measurement accuracy, reliability impact, etc., achieve long service life, reliable data transmission, and achieve protection functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

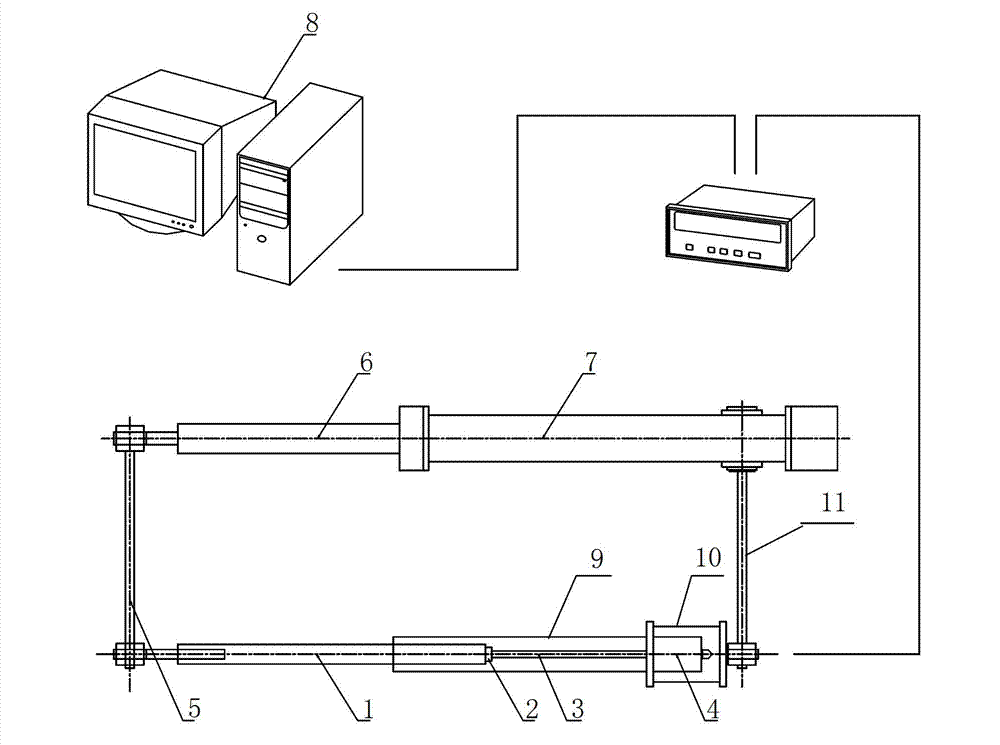

[0016] See figure 1 , position detection system with auxiliary cylinder, including built-in displacement sensor 4, auxiliary cylinder piston cylinder 1, position detection magnet 2, magnetostrictive waveguide 3, auxiliary cylinder outer wall 9, pull rod 5, the system puts the position detection device on the outside On the running mechanism, the position of the running mechanism is detected by the principle of synchronous operation of the position detection magnet 2 and the running mechanism. The movable end 6 of the running mechanism and the fixed end 7 of the running mechanism are respectively provided with a pull rod device 5, which is connected to the movable end 6 of the running mechanism. The other end of the tie rod device 5 is connected w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap