Method for visually testing internal molding shrinkage characteristic of high polymer material

A polymer material, molding shrinkage technology, applied in the analysis of materials, material analysis by optical means, measuring devices, etc., can solve the quantitative determination and analysis of the inability to mold shrinkage, and restrict the improvement and development of precision molding technology, etc. problems, to achieve the effect of improving the level of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The best embodiment of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

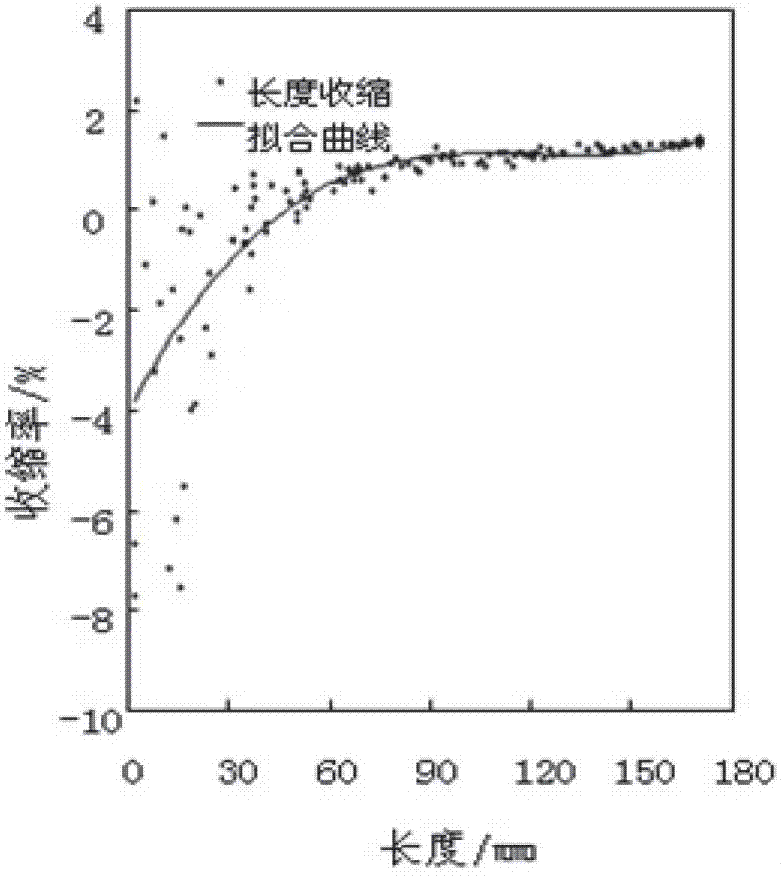

[0030] This example is used for the visual analysis of the internal shrinkage of the poured molded product of the polyurethane elastomer flat plate. The product is a rectangular parallelepiped plate with a size of 170×100×10mm.

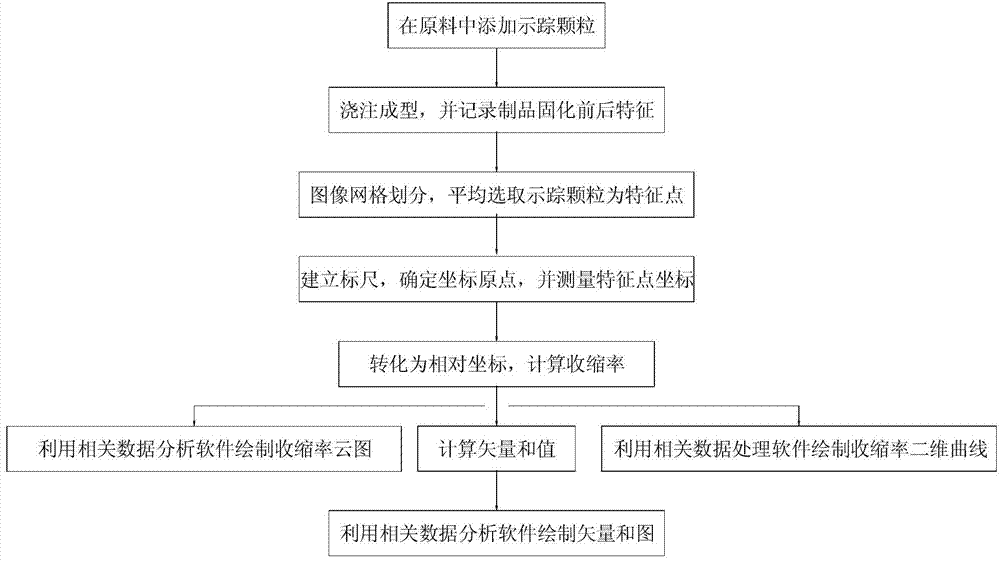

[0031] Embodiment steps are as follows:

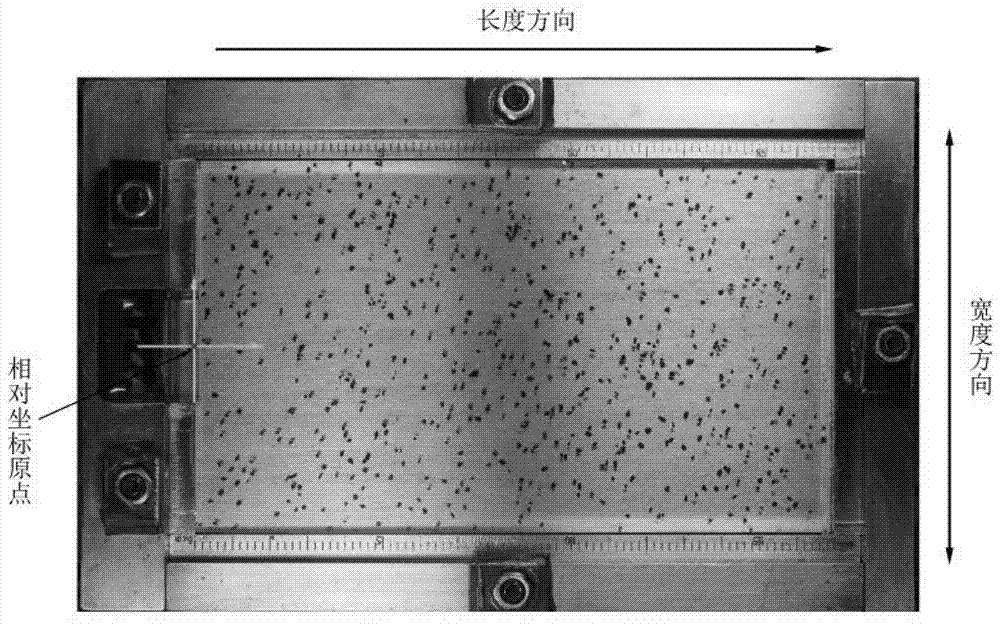

[0032] 1) In the experiment, take the mold cavity as a reference scale, and record the images of the product before molding and curing and after curing and stabilization;

[0033] 2) Divide the product area equally in the form of 8×6 grids (length×width) in Photoshop, and then select 3 to 4 relatively clear feature points in each grid by using the two pictures as a mutual reference, and pay attention to ensuring the feature points Uniformity of bit distribution;

[0034] 3) Measure the coordinate position of each side of the product, and determine the coor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com