Automatic printing and managing system for bar code

An automatic printing and management system technology, applied in the engineering field, can solve problems such as chip program programming errors, product quality is difficult to guarantee, board position assembly dislocation, etc., to achieve the effect of complete material information, improve production efficiency, and ensure product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

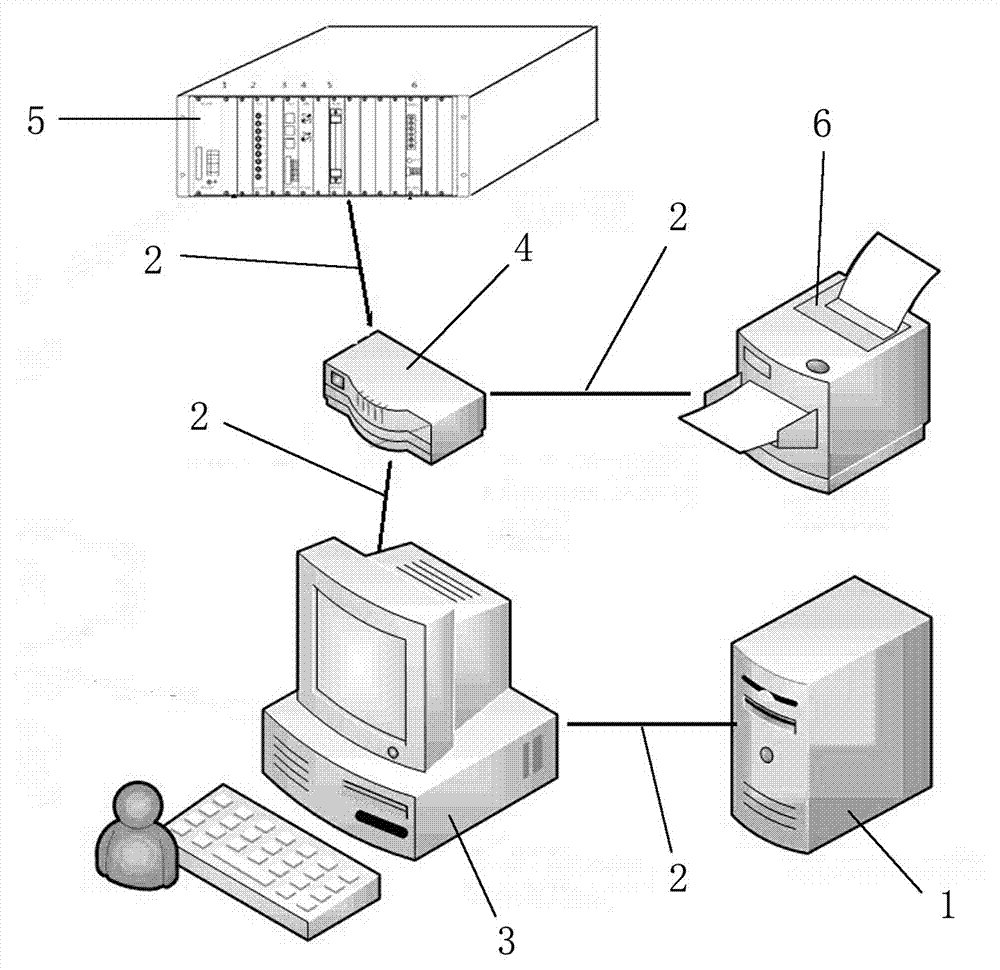

[0021] refer to figure 1 , the barcode automatic printing and management system of the present invention includes: a database server 1, a terminal computer 3 that realizes data connection with the database server 1 through the data line 2, a program burner 4 that realizes the data connection with the terminal computer 3 through the data line 2, and A bar code printer 6 that realizes data connection with the program burner 4 through the data line 2 .

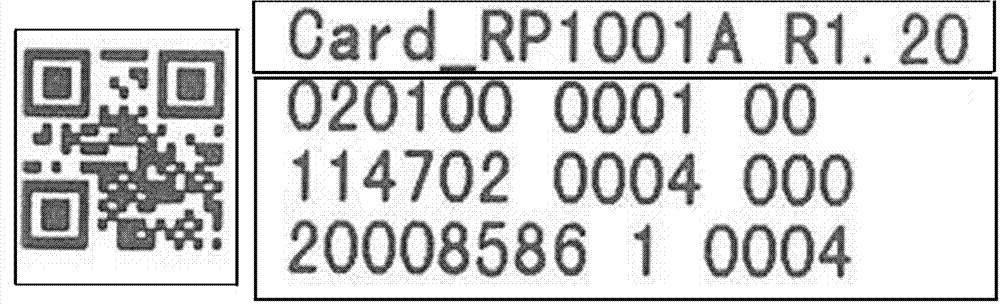

[0022] The debugger sends the terminal program instructions to the program programmer 4 through the terminal computer 3. After receiving the instructions, the program programmer 4 writes the program into the board chip of the electrical protection device 5. After the burning program is completed, the program burner The device 4 sends a print command to the barcode printer 6 connected to it,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com