Filter capacitor

A technology of filter capacitors and capacitors, which is applied to the terminal of fixed capacitors, the casing/package of fixed capacitors, and the components of fixed capacitors, etc., can solve problems such as increased contact resistance, poor contact at electrodes, and affecting the operation of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

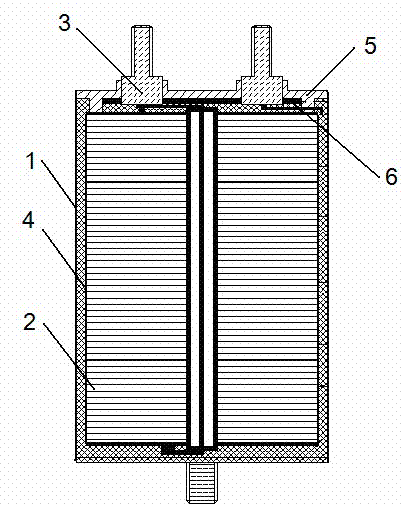

[0017] Embodiment 1: as figure 1 As shown, a filter capacitor related to the present invention includes a capacitor shell, two capacitor cores packaged in the shell, two electrode bolts, a positioning plate and an insulating anti-torsion plate; wherein, the two electrode bolts pass through the positioning plate in turn. The positioning holes of the anti-torsion plate and the anti-torsion plate are connected to the upper and lower gold-sprayed layers of the capacitor core by welding through copper sheets; the epoxy resin of the capacitor package seals and fixes the positioning part of the entire torsion plate and electrode bolts .

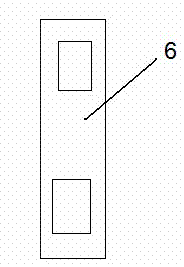

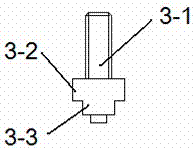

[0018] Such as figure 2 , image 3 , Figure 4 As shown, the electrode bolt is divided into a positioning part with an integrated structure, a boss and an external part. The external part is provided with threads, and the cross-section of the positioning part can be a non-circular structure such as a polygon or an ellipse. The entire bolt is mad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com