Capping machine with synchronous tensioning mechanism

A technology of tensioning mechanism and cap locking machine, which is applied in the direction of mechanical equipment, flanged bottle caps, belts/chains/gears, etc., and can solve problems such as difficulty in guaranteeing the quality of caps, low production efficiency, and large manual operations. , to achieve the effect of expanding machine performance and application range, reducing work intensity and labor costs, and improving product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

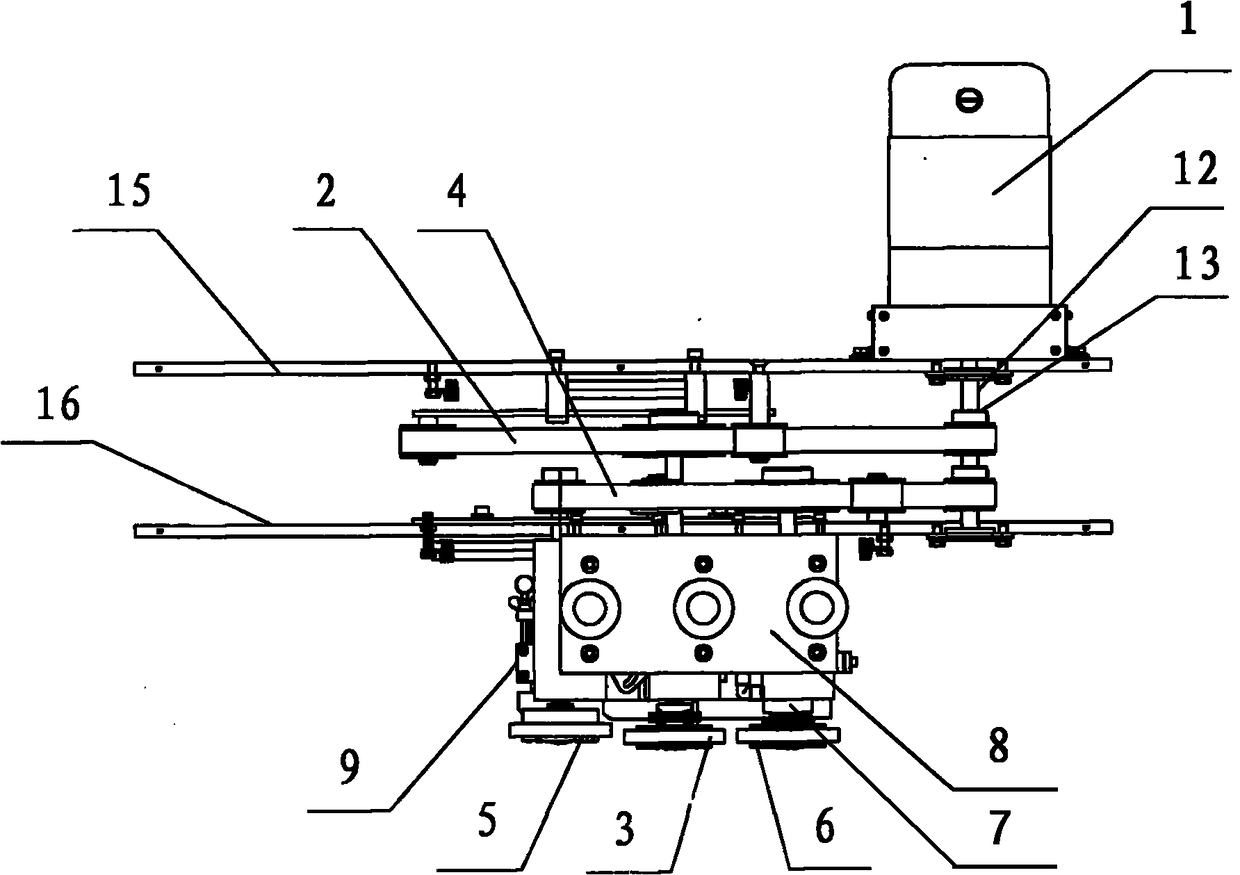

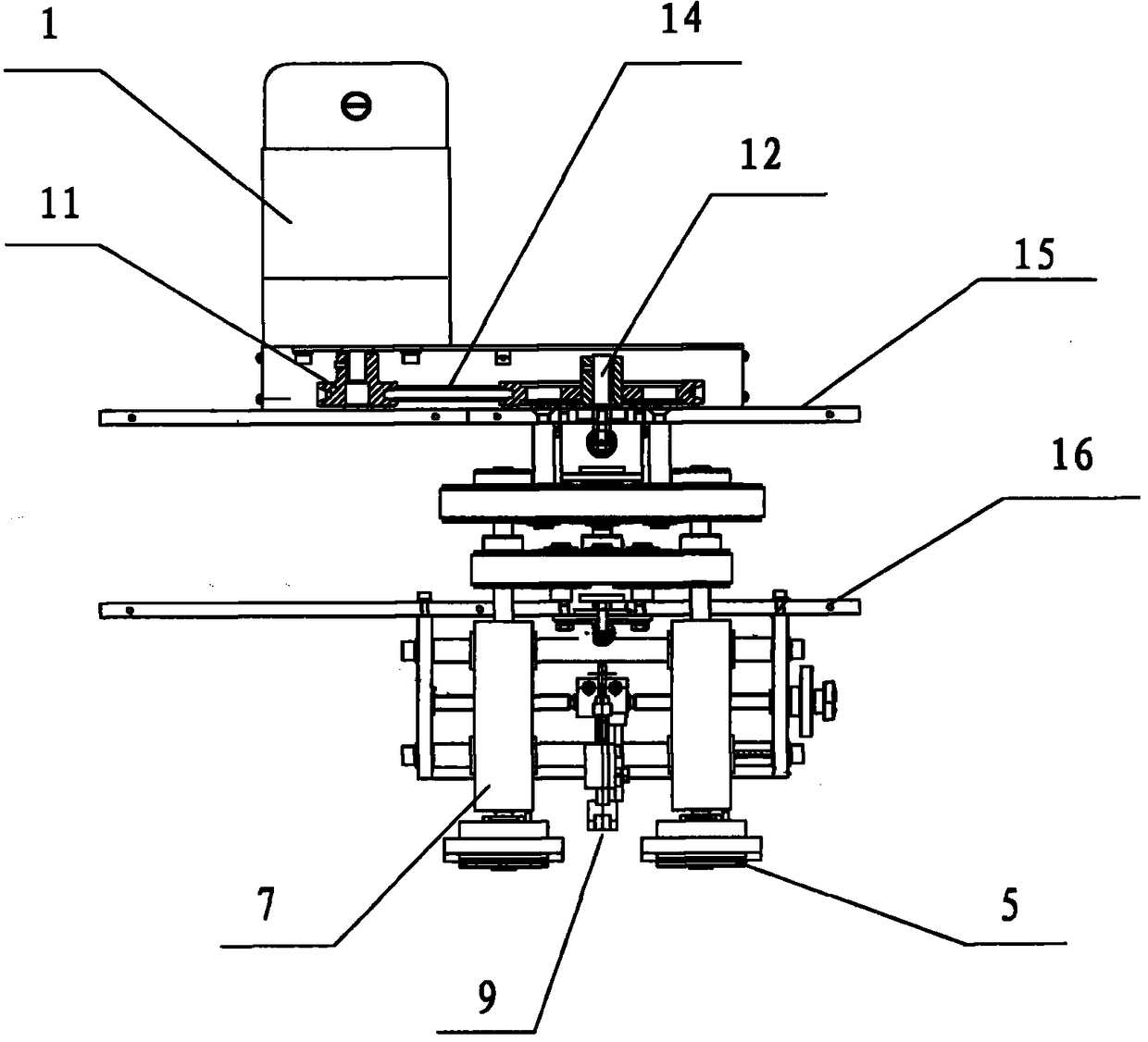

[0018] according to Figure 1~2 The specific structure of the present invention will be described in detail. The capping machine with a synchronous tensioning mechanism includes a motor 1, two sets of transmission parts, and a capping disc; the upper transmission part fixed on the upper mounting plate 15 includes an upper timing belt 2, a pair of second group of timing belt tensioning wheels 3. The shaft of the second group of synchronous belt tensioner 3 is fixed with the second group of capping disc assembly, and the upper synchronous belt 2 is set on the synchronous pulley 13 synchronously driven by the motor 1; the lower one fixed on the lower mounting plate 16 The transmission components include the lower synchronous belt 4, a pair of the first synchronous belt tensioner 5, a third synchronous belt tensioner 6; the first synchronous belt tensioner 5 and the third synchronous belt tensioner The first set of capping disc assemblies and the third set of capping disc assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com