Secondary Insulation Method for Positive Pole of High-voltage Ni-MH Storage Battery

A nickel storage battery and secondary insulation technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of battery safety hazards, battery short circuits, etc., and achieve the effect of improving safety and increasing insulation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0015] The preparation process of the secondary insulation of the positive pole column inside the high-voltage nickel-hydrogen battery of the present invention:

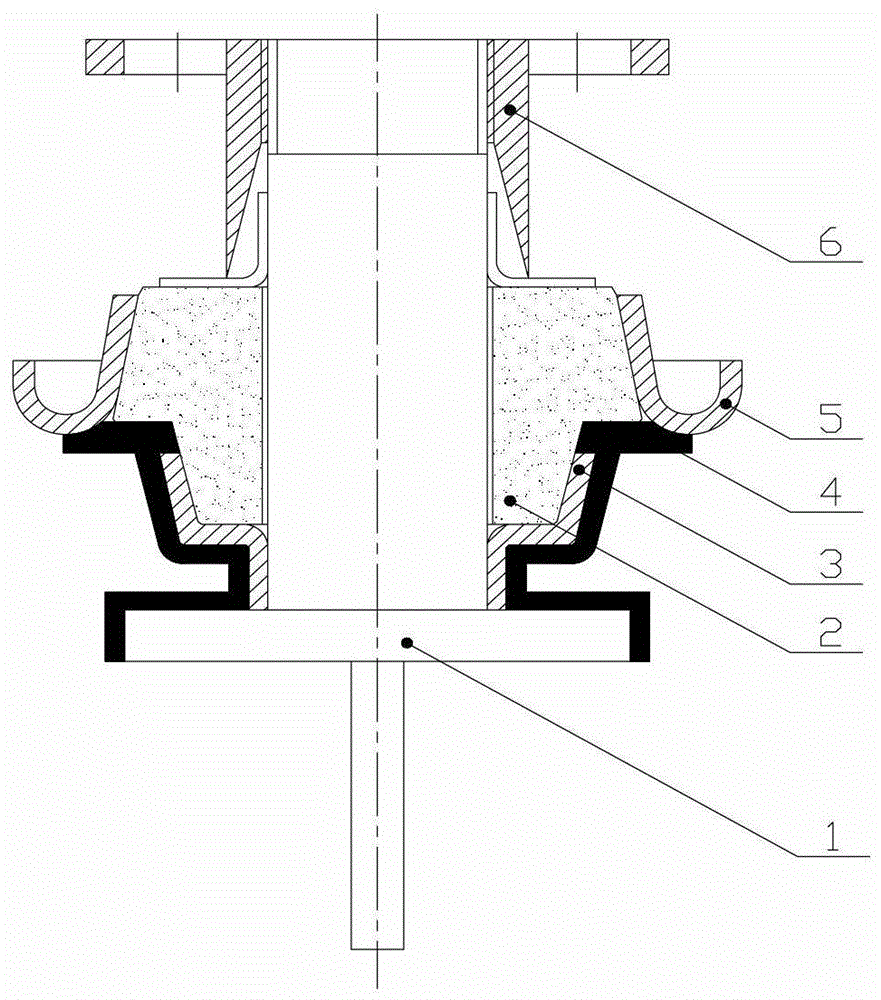

[0016] Such as figure 1 As shown, a pole rod 1 with a small shaft at both ends and a large shaft in the middle is made of nickel, and the small shaft is made as a threaded shaft near the end; the lower transition sleeve 3 with a small hole and a tapered hole is made of nickel The small hole of the lower transition sleeve can be set on the small shaft with threaded shaft of the pole rod; the ceramic sleeve 2 is made of ceramics and set on the small shaft with threaded shaft of the pole rod; the clamp is made of nickel alloy The transition ring 5 on the ceramic sleeve; the connecting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com