10kv cable molded intermediate joint heating equipment

A technology of intermediate joints and heating equipment, applied in the direction of ohmic resistance heating parts, etc., can solve the problem of long time consumption, and achieve the effect of ensuring personal safety, saving time and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

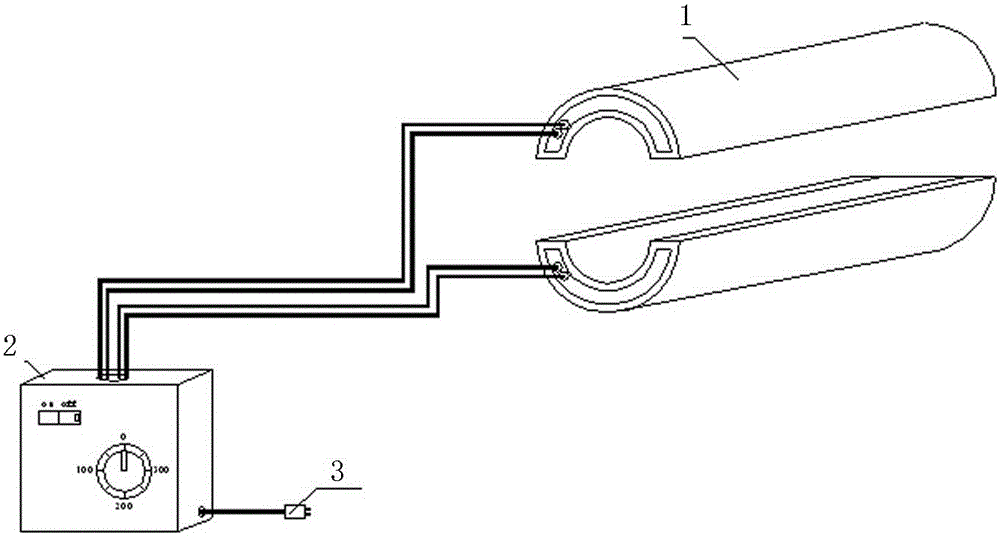

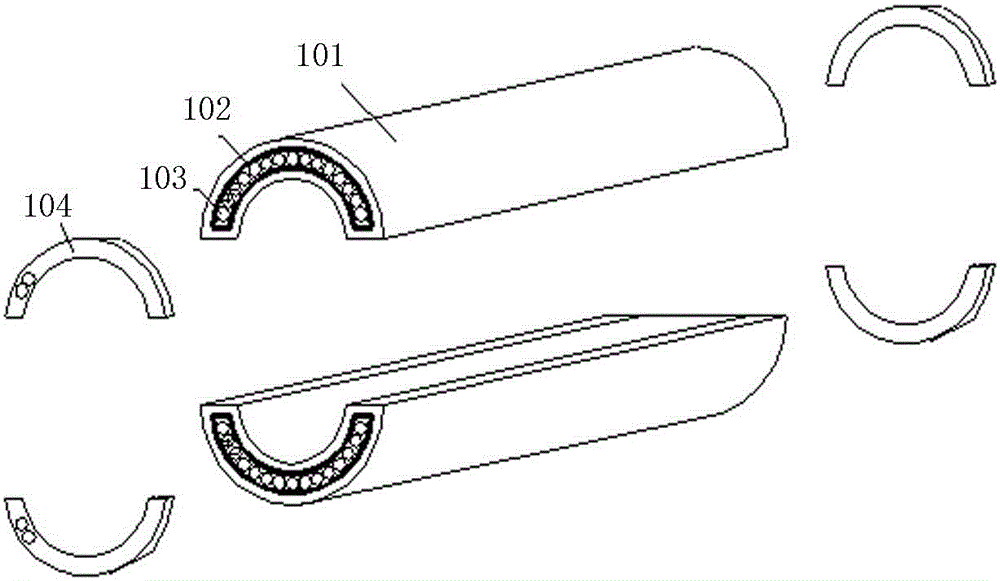

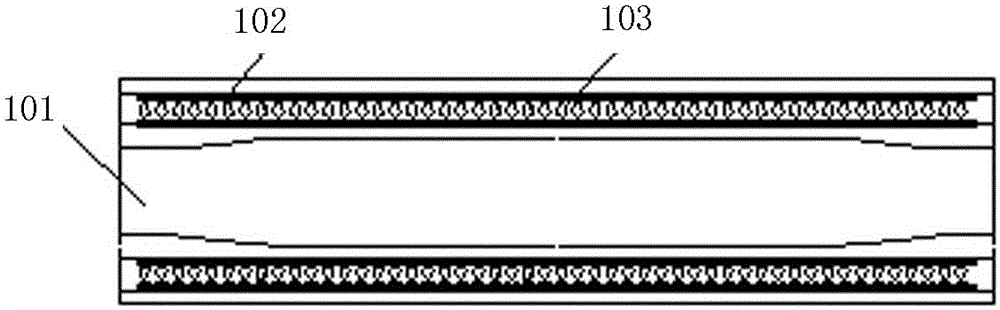

[0025] Such as Figure 1-3 As shown, the mold 1 is connected to the thermostat 2, and the thermostat 2 is provided with a plug 3; the mold 1 is set to be hollow, and the inner cavity of the mold 1 is provided with a heating resistor 103, and the heating resistor 103 runs through the entire mold 1, The outer surface of the heating resistor 103 is covered with the aluminum nitride ceramic insulating and heat-conducting layer 102 . Both ends of the mold 1 are provided with a blocking cover 104, and a detachable rubber insulating pad is provided on the blocking cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com