A method for improving copper clad laminate and pcb warping or twisting deformation

A copper clad laminate and warping technology, applied in the field of electronic materials, can solve the problems of high cost, complex process, unfavorable large-scale industrial application, etc., and achieve the effect of low cost, simple operation, and favorable large-scale industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

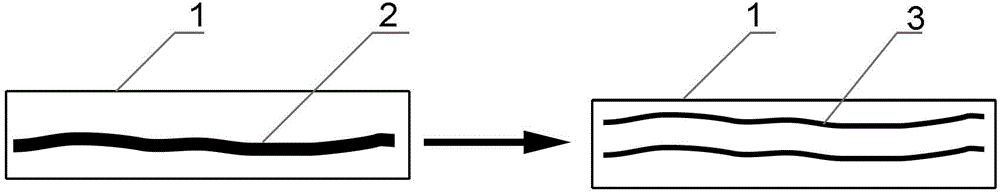

Method used

Image

Examples

Embodiment 1

[0077] Example 1: Bending strength and deformation resistance of plates with the same thickness and different composition structures. The structure of the copper clad laminate is shown in Table 1 to Table 4.

[0078] Table 1

[0079]

[0080]

[0081] Table 2

[0082]

[0083]

[0084] table 3

[0085]

[0086]

[0087] Table 4

[0088]

[0089]

[0090] For the analysis results of the experimental data in Tables 1 to 4, see Figure 3~Figure 14 shown.

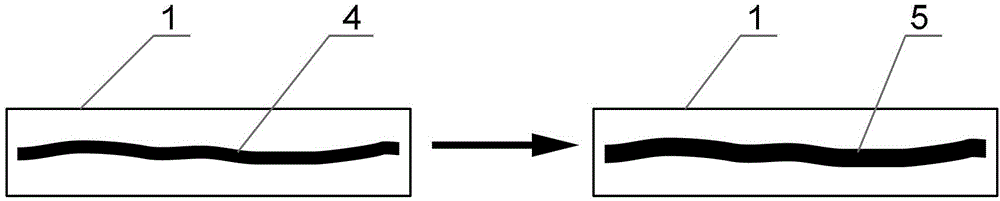

[0091] 1. Tensile strength

[0092] From the results of tensile strength data analysis, for the same thickness of the plate, the tensile strength of S1141 / S1000 / S1000-2 / S1155 does not change purely with the RC and ingredient structure, but is a process of mutual influence, mainly The following two rules:

[0093] (1) In general, as the weight fraction of glass cloth in the sheet decreases, the tensile strength of the sheet also decreases;

[0094] (2) For the 1×7628 and 2×2116 structures with almo...

Embodiment 2

[0099] Embodiment 2: Rigidity comparison of plates containing different numbers of glass cloths

[0100] The structure of the copper clad laminate is shown in Table 5~Table 6.

[0101] In order to further prove that when the RC is almost the same, whether the rigidity of multiple sheets of glass cloth is really better than that of sheets with fewer sheets of glass cloth, the test is carried out, and the results are shown in Table 5~Table 6.

[0102] table 5

[0103]

[0104]

[0105] Table 6

[0106]

[0107]

[0108] For the analysis results of the experimental data in Table 5 to Table 6, see Figure 15~Figure 18 shown.

[0109] The data shows that in the case of almost equal glass cloth weight fractions, the rigidity of the sheet with multiple glass cloth structures is better than that of a single sheet structure.

Embodiment 3

[0110] Embodiment 3: Storage modulus of different batching structural plates

[0111] The structure of the copper clad laminate is shown in Table 7~Table 8.

[0112] Table 7

[0113]

[0114] Table 8

[0115]

[0116] For the analysis results of the experimental data in Table 7 to Table 8, see Figure 19~Figure 20 shown.

[0117] The data analysis results of the storage modulus show that for the plates with the same thickness, the change law of the storage modulus of S1141 / S1000 / S1000-2 / S1155 is consistent with the tensile strength and bending strength, that is, it does not simply vary with the glass cloth structure and RC and change, is the interaction of the two:

[0118] (1) In general, as the weight fraction of glass cloth in the plate decreases, its storage modulus decreases;

[0119] (2) However, for sheets of the same thickness with comparable weight fractions of glass cloth, the storage modulus of sheets with multiple sheets of glass cloth is better than tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com