Blade for electrophotography

A squeegee and polyurethane technology, which is applied to circuits, electrical recordings, electrical components, etc., can solve the problems of squeegee application and squeegee reversal, and achieve the effects of reducing load, increasing printing speed, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

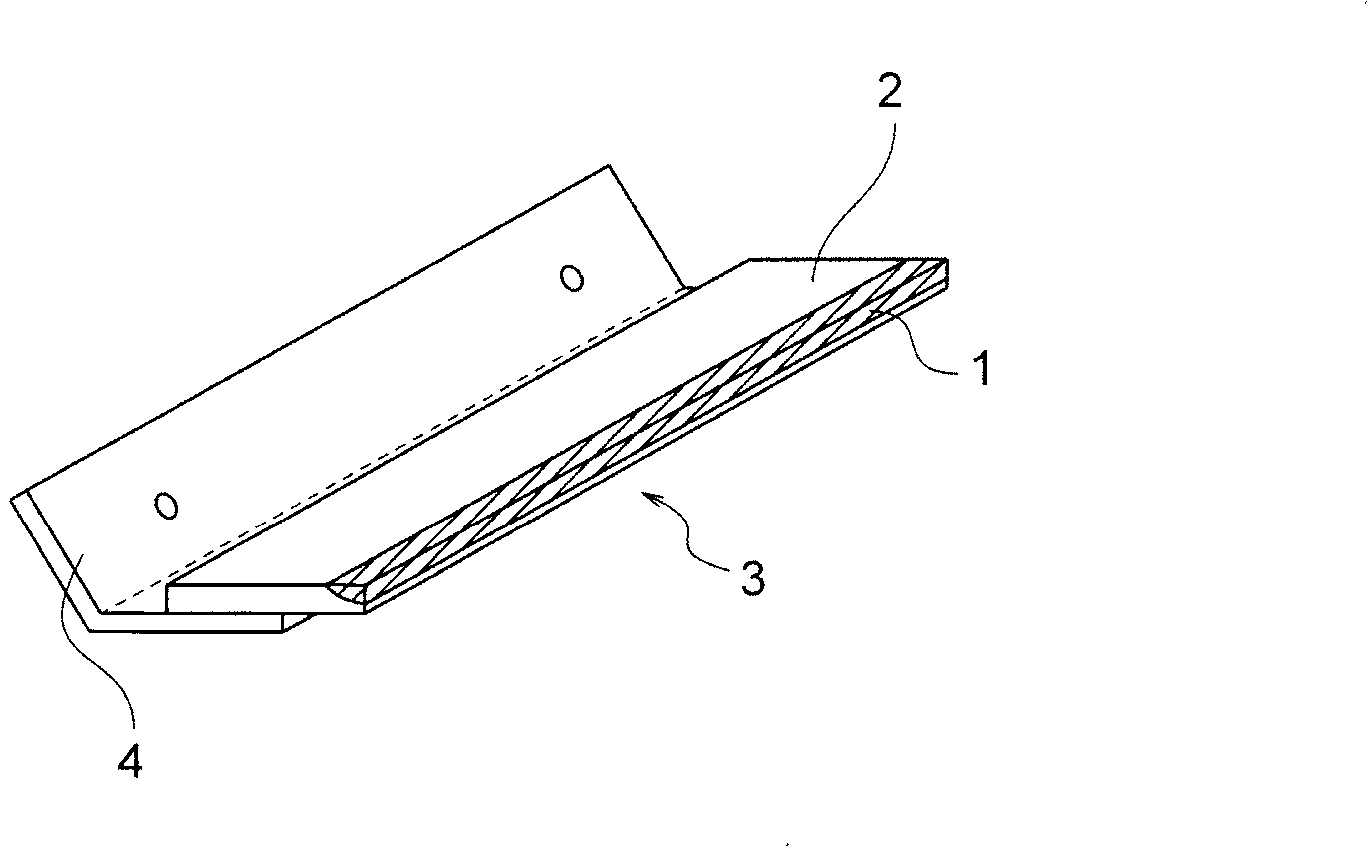

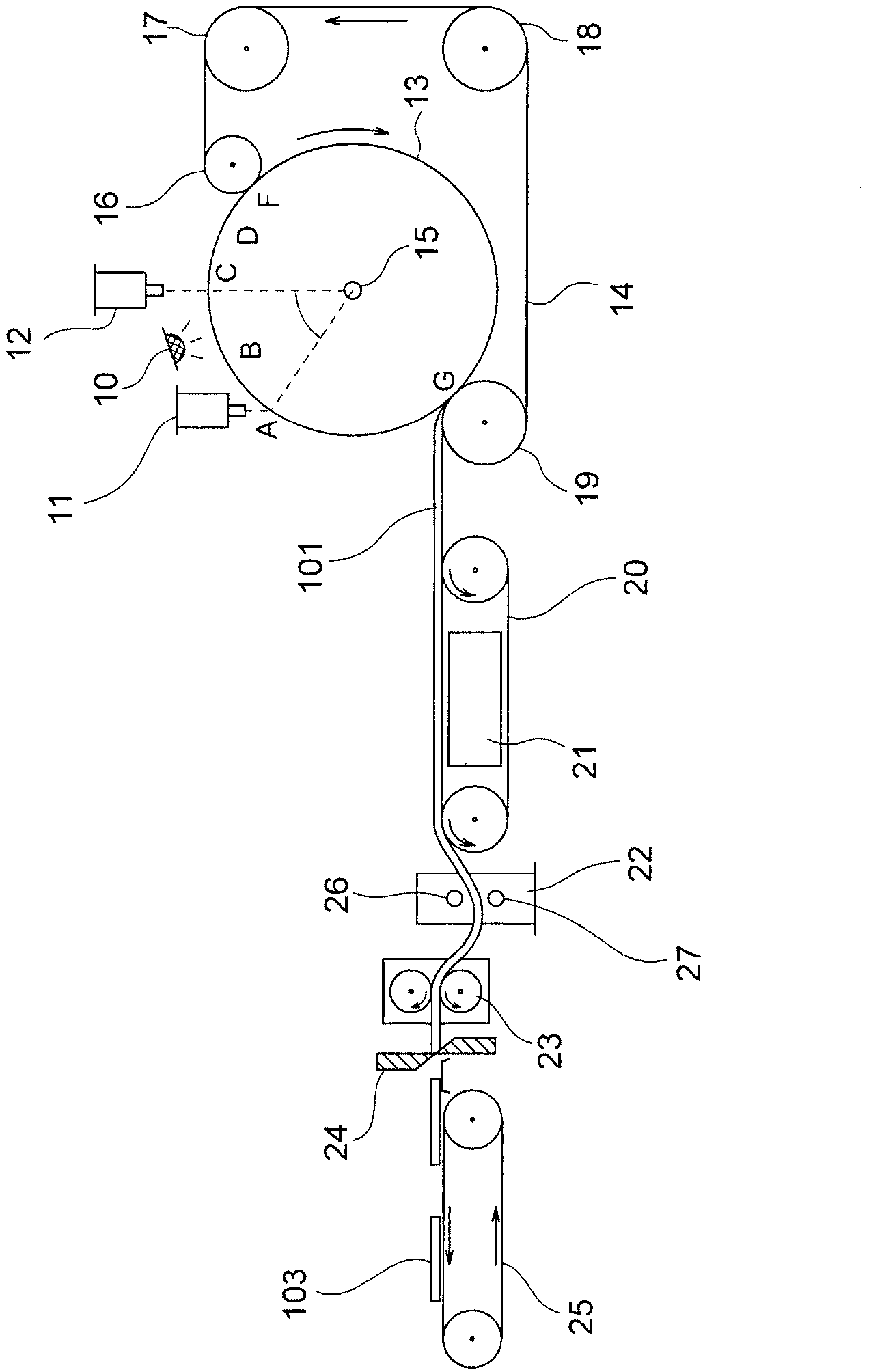

[0159] An example of the blade for cleaning the blade is shown. The manufacturing method uses a continuous molding method using a rotating molding drum that forms grooves on the outer periphery.

[0160]

[0161] Polyurethane elastic rubber member: thickness 2.0mm, width 12.3mm, length 326mm

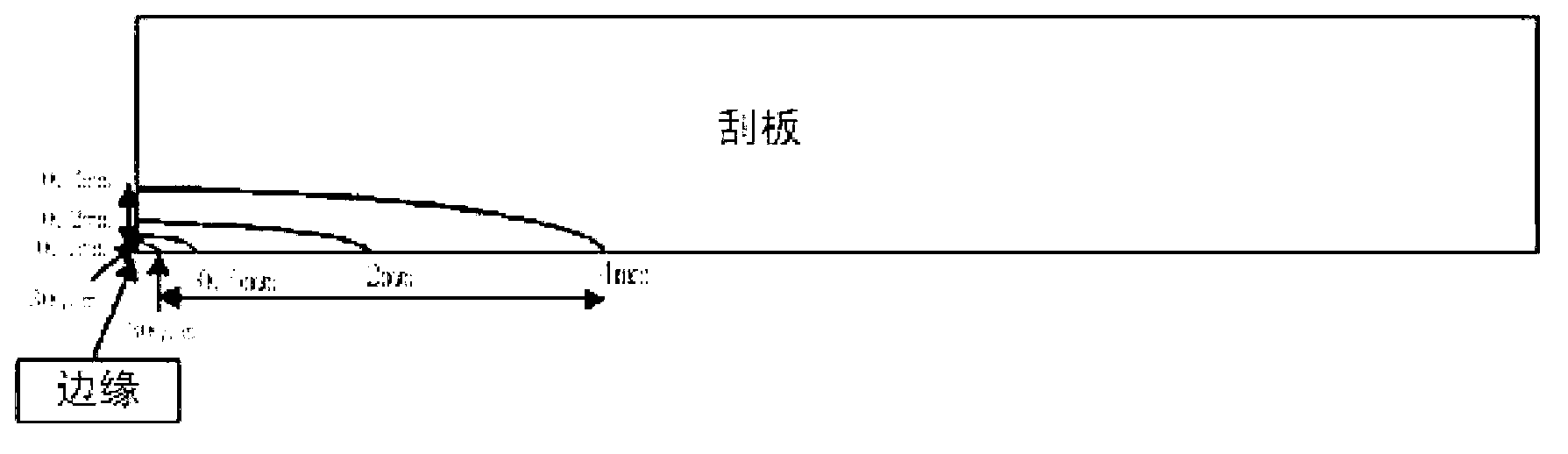

[0162] The size of the edge: the size shown in Table 2

[0163] Metal support body: steel plate with a thickness of 1.2mm

[0164] Adhesive treatment: use dimer acid type hot melt adhesive

[0165]

[0166] The combination of ester urethane and ether urethane used in the edge layer or base layer is as shown in Table 1. Table 3 shows combinations and evaluations of urethanes.

[0167] Table 1

[0168]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com