Cyclic slurry feeding system of coating machine

A coating machine and slurry technology, applied in the field of coating machine slurry circulation feeding system, can solve problems such as no good solution, achieve good coating quality consistency, reduce coating particles, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

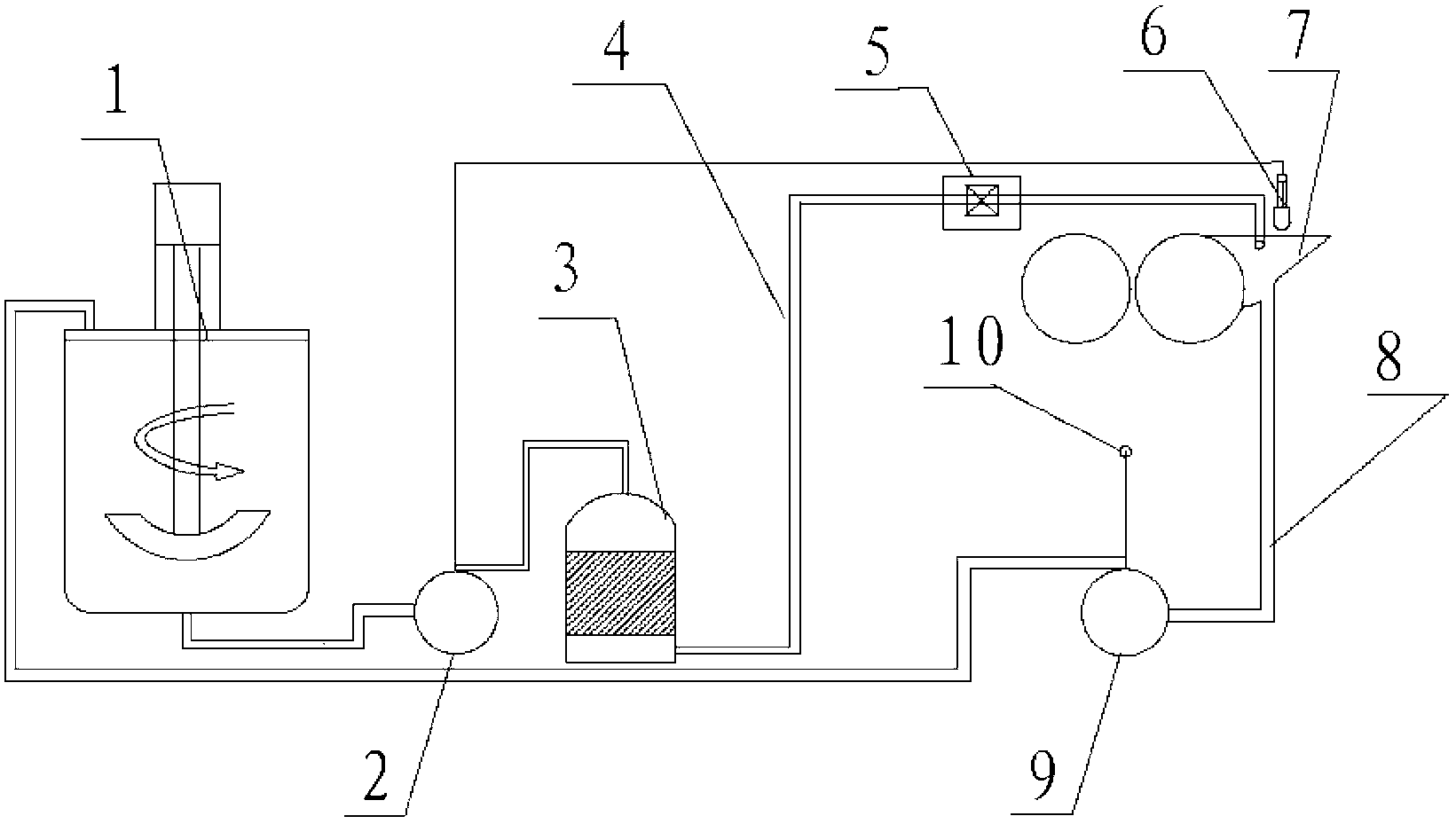

[0014] As shown in the figure: a coating machine slurry circulation feeding system, the system includes a slurry transfer tank 1, the top and bottom of the slurry transfer tank are respectively connected with a return pipeline 8 and a feeding pipeline 4; The circulating feeding system includes an automatic feeding part and an automatic returning part; wherein the feeding part includes a feeding diaphragm pump 2, a slurry filtering iron remover 3 and a liquid level sensor 6; the feeding diaphragm pump and the slurry filtering remove The ironware is connected to the coater trough 7 through the feeding pipeline; the return part includes the return diaphragm pump 9 and the controller 10 on it, and the slurry transfer tank 1 and the coater trough are respectively connected through the return pipeline 7.

[0015] The feeding diaphragm pump 2 is controlled by a liquid level sensor 6 located in the feed tank 7 of the coater.

[0016] The slurry transfer tank 1 is made of stainless st...

Embodiment 2

[0020] As shown in the figure: a coating machine slurry circulation feeding system, the system includes a slurry transfer tank 1, the top and bottom of the slurry transfer tank are respectively connected with a return pipeline 8 and a feeding pipeline 4; The circulating feeding system includes an automatic feeding part and an automatic returning part; wherein the feeding part includes a feeding diaphragm pump 2, a slurry filtering iron remover 3 and a liquid level sensor 6; the feeding diaphragm pump and the slurry filtering remove The ironware is connected to the coater trough 7 through the feeding pipeline; the return part includes the return diaphragm pump 9 and the controller 10 on it, and the slurry transfer tank 1 and the coater trough are respectively connected through the return pipeline 7.

[0021] The feeding diaphragm pump 2 is controlled by a liquid level sensor 6 located in the feed tank 7 of the coater.

[0022] The slurry transfer tank 1 is made of stainless st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com