Method for correcting machined workpiece angles

A technology for processing workpieces and angle correction, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems of low accuracy, time-consuming and laborious, etc., and achieve the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

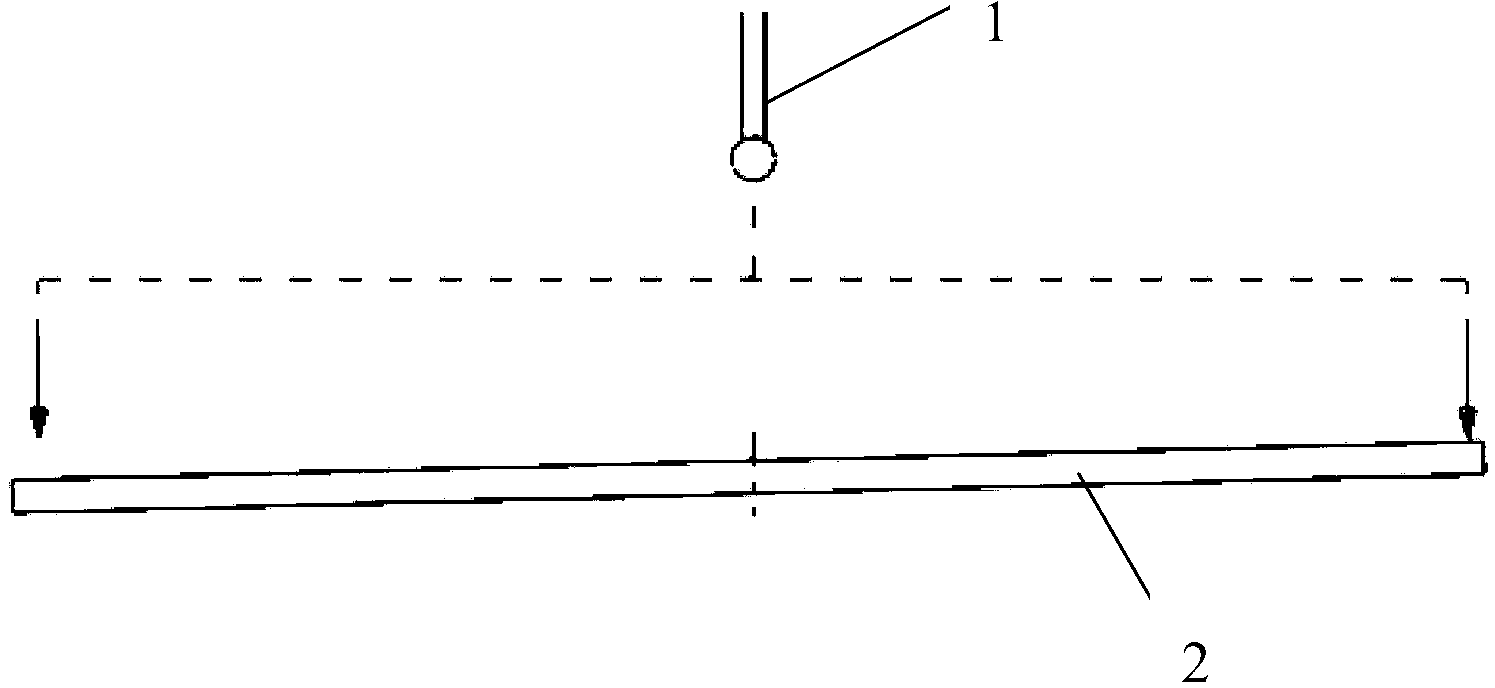

[0025] refer to figure 1 , a machining workpiece angle correction method, the correction method comprises the following steps:

[0026] (1) The workpiece 2 is preliminarily aligned on the worktable, the rough alignment distance of the preliminary alignment cannot exceed 10mm, and the workpiece is clamped;

[0027] (2) The machine tool controller controls the operation detection of the measuring head 1, and the process is as follows:

[0028] 2.1), set the coordinate system, and quickly locate the X and Y axes of the machine table to the first alignment point;

[0029] 2.2) Execute the length compensation of the measuring head and position the Z axis to 30mm of the workpiece;

[0030] 2.3) Then approach the workpiece at a slow speed of 7mm, start the first alignment point measurement, and after alignment return to the safe point, the alignment data will be automatica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com