Automatic early warning winding device

A winding device, automatic warning technology, applied in the directions of transportation and packaging, transportation of filamentous materials, thin material processing, etc., can solve the problems of insufficient winding, time-consuming and labor-intensive, winding degree, etc. Efficiency and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

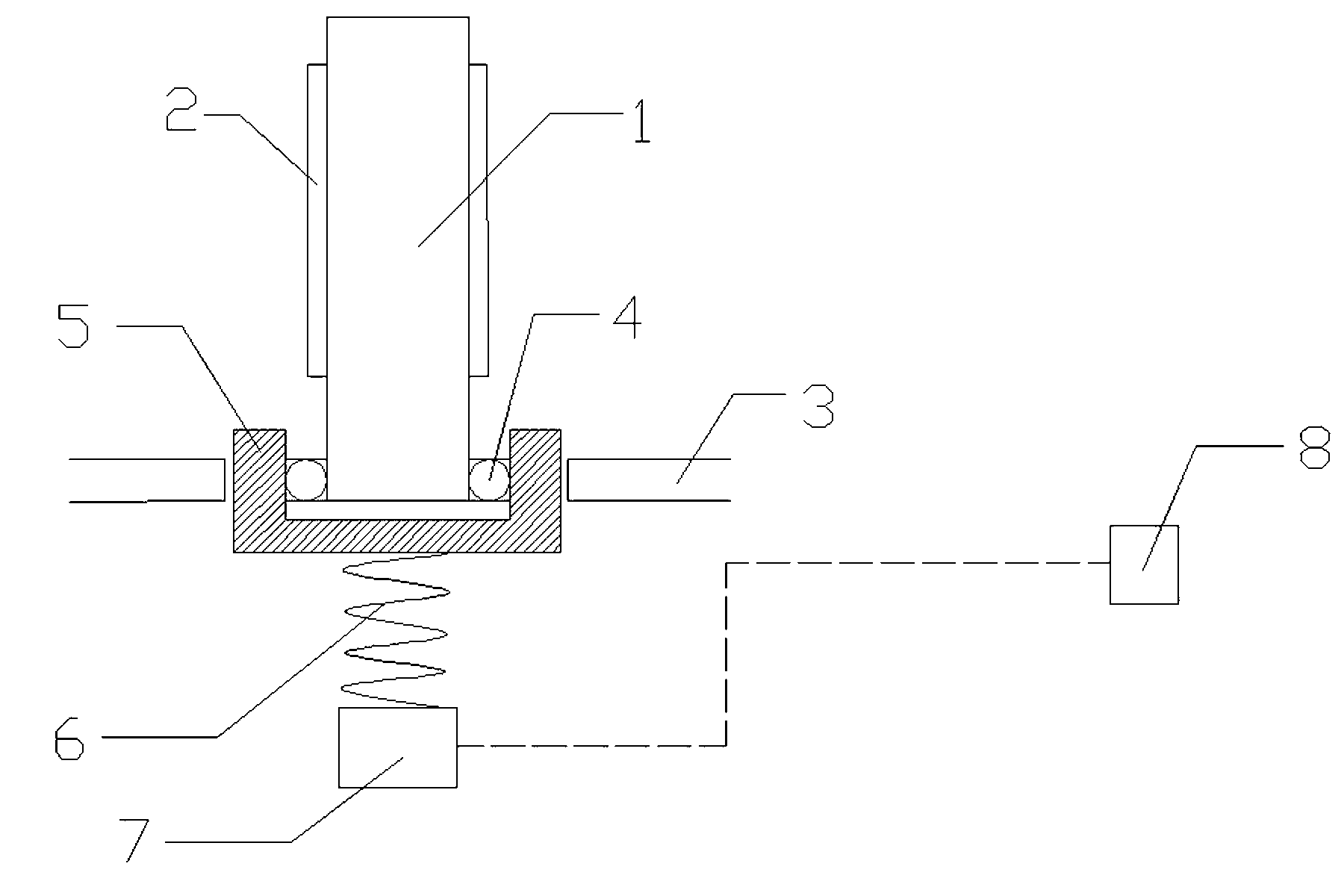

[0013] Such as figure 1 The automatic early warning winding device includes a winding shaft 1, a winding tube 2 and a placement table 3, the winding tube 2 is sleeved on the outside of the winding shaft 1, and a bearing 4 is arranged at the bottom of the winding shaft 1, and the bearing 4 A U-shaped pallet 5 is arranged below, and the winding shaft 1 and the U-shaped pallet 5 are connected by bearings 4 . Keep a distance between the U-shaped pallet 5 and the placement table 3 without contact. As a preferred solution, this distance is 1-3 mm, so that the U-shaped pallet 5 can move up and down inside the placement table 3 .

[0014] A spring 6 is provided below the U-shaped pallet 5, and a pressure sensor 7 is provided below the spring 6, and the pressure sensor 7 is connected to the early warning device 8. When the textile machine starts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com