Beverage product with stable dairy foam

A product, milk foam technology, applied in the direction of milk preparations, dairy products, food ingredients, etc., can solve the problem of insufficient stability of toppings, and achieve the effect of enhancing stability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] cold coffee drink

[0043] a) Preparation of coffee liquid:

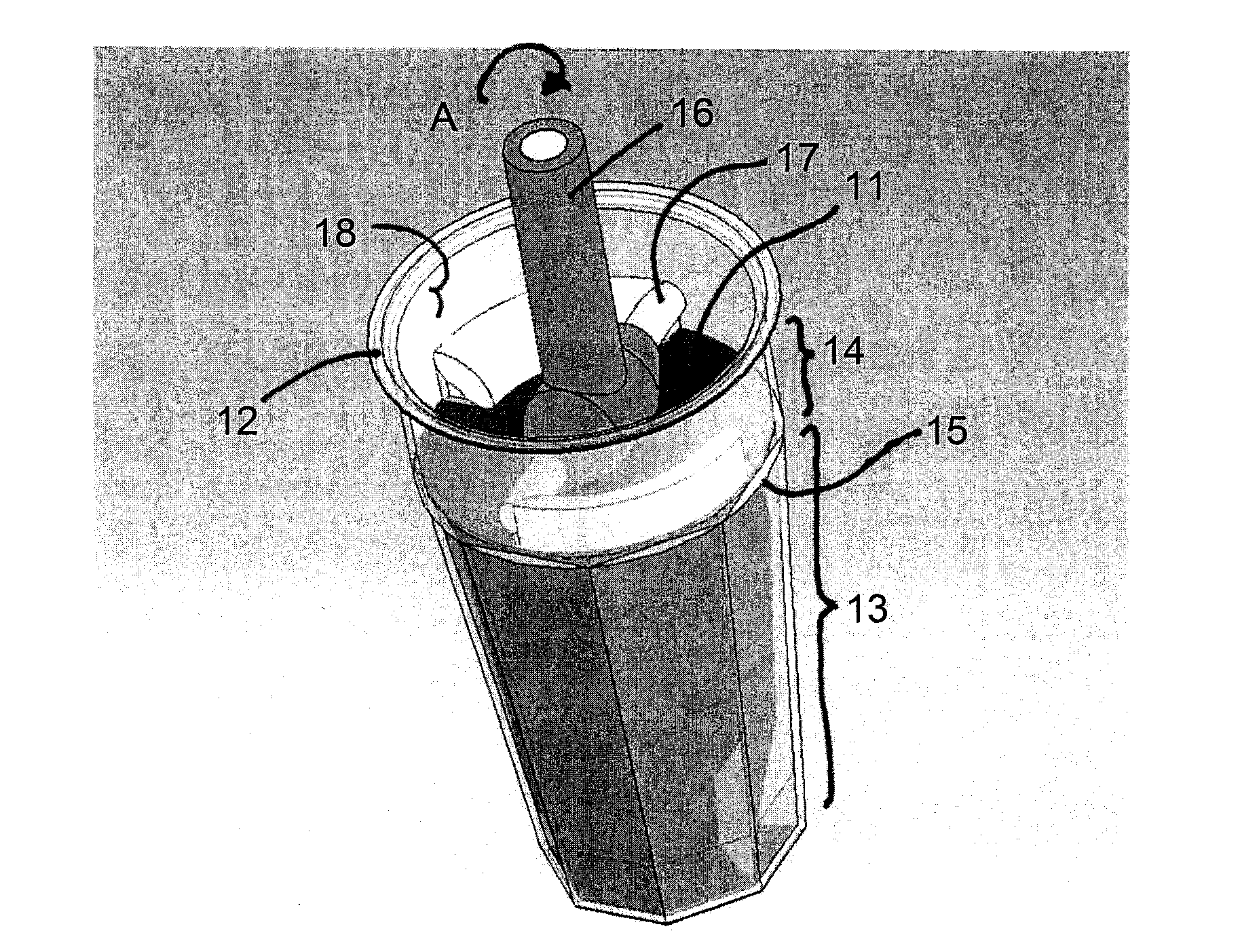

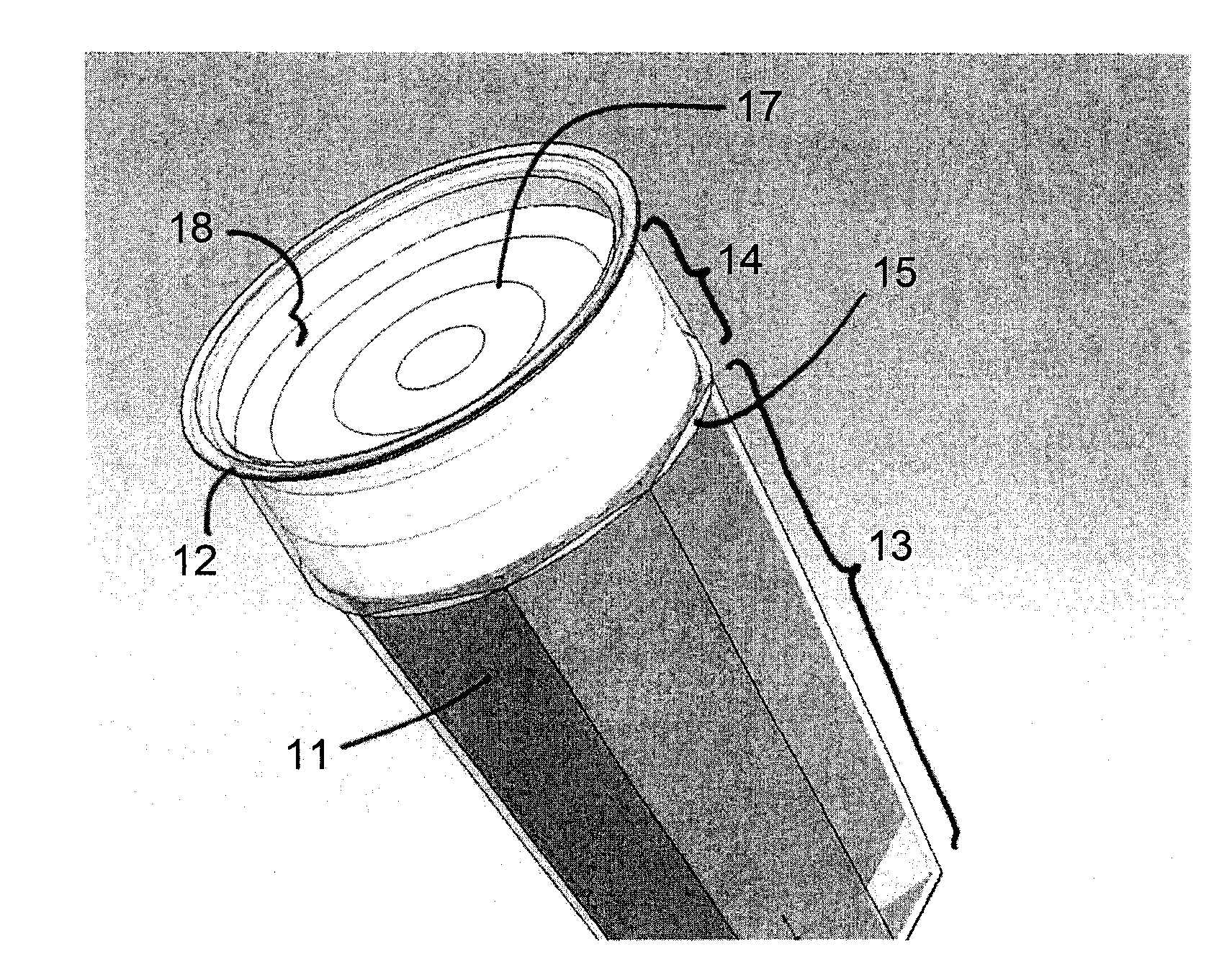

[0044] Commercially available dried coffee extract, sucrose and milk protein were mixed together and added to a liquid phase comprising milk, cream and water for standardization. After hydration, the mixture was briefly sterilized at high temperature and thereafter homogenized. The resulting coffee liquid is then cooled to a temperature of 6°C and filled into transparent plastic cups such as figure 1 shown in .

[0045] b) Preparation of milk foam:

[0046] A mixture of dry stabilizers, ie, 150 g carrageenan, 50 g xanthan gum and 8 g locust bean gum, was added to 100 liters of standardized liquid milk containing whole milk, cream and 6.5 wt% sucrose. After hydration, the milk-based composition was sterilized at 145°C for 60 seconds. Thereafter, the composition was cooled to 6°C.

[0047] The milk mixture was then whipped with a standard industrial aerator of the Aeromix type at a temperature of 8°C by i...

example 2

[0054] Mango Flavored Fermented Milk Drink

[0055] a) Preparation of fermented milk liquid:

[0056] The milk was mixed with sucrose and pasteurized at 92°C for 6 minutes. Thereafter, the milk liquid was homogenized and cooled to 41° C. before being inoculated with the yoghurt strain used for fermentation. Once pH 4.6 was reached, the fermentation was stopped and mango puree was added to the liquid and mixed. Cool the liquid to 6 °C and fill into clear plastic cups such as figure 1 shown in .

[0057] b) Preparation of fermented milk foam

[0058] 500 g of lactoyl palmitin emulsifier and 500 g of dry gelatin were added to 100 liters of liquid whole milk containing 5 wt % cream and 5 wt % sucrose, and mixed.

[0059] After hydration, the milk base was pasteurized at 105° C. for 2 minutes and then homogenized first at 200 bar and in a second step at 40 bar. The milk base was then cooled to 41°C before being inoculated with the yogurt strain used for fermentation. Once th...

example 3

[0068] Comparative Example I of Coffee Beverages

[0069] As in Example 1, coffee liquid was prepared and dosed into clear plastic cups.

[0070] A milk mix was prepared with the same standardized liquid milk comprising whole milk, cream and 6.5 wt% sucrose as in Example 1, but without added stabilizers, namely carrageenan, xanthan gum and locust bean gum. The milk mixture was then sterilized, cooled and whipped in the same manner as the milk mixture in Example 1.

[0071] Such as figure 1 The resulting milk froth is applied to a clear plastic cup containing coffee liquid as shown in .

[0072] The cups were then stored at 8°C for several days and observed daily. It was thus observed that for the beverage product samples without stabilizer in the milk foam, the milk foam started to shrink after 1 day (24 hours), ie collapsed and mixed into the liquid. By the next day (48 hours), the milk froth was no longer sticking to the inside of the cup, and remnants of the milk froth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com