Method for preparing polymer porous microspheres by high-voltage electrostatic anti-solvent process

A porous microsphere, high-voltage electrostatic technology, which is used in the preparation of microspheres, microcapsule preparations, inorganic non-active ingredients, etc., can solve the problems of hollow, non-porous and non-penetrating microsphere surfaces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

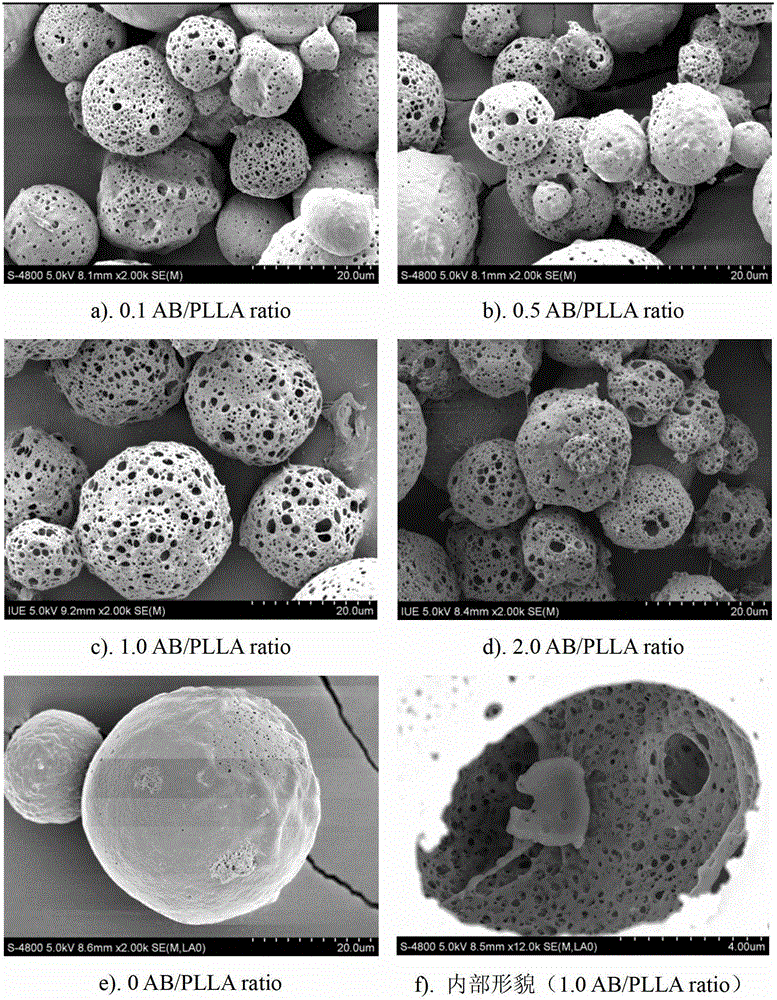

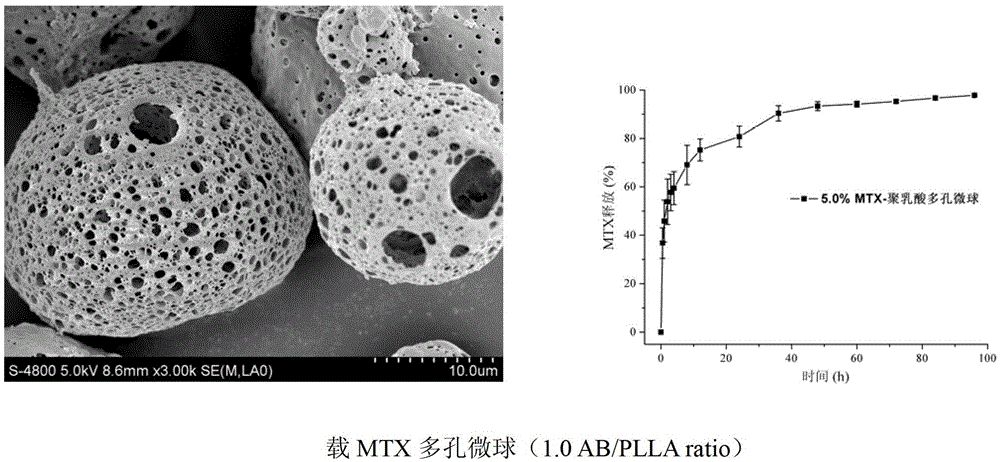

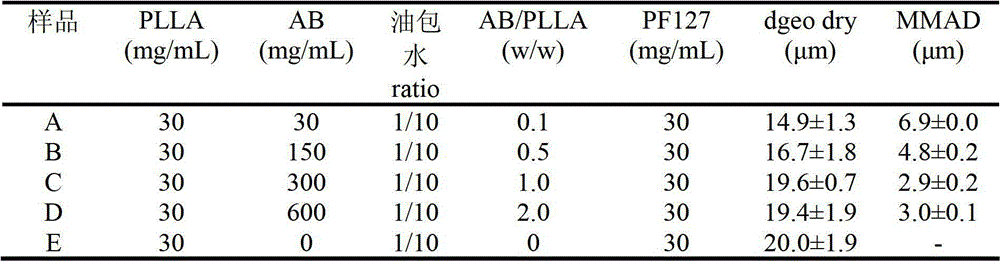

[0019] The amount of ammonium bicarbonate added was changed, and polylactic acid porous microspheres were prepared by high-voltage electrostatic antisolvent method, as shown in Table 1. figure 1 The preparation procedure is as follows: 150 mg PLLA and 150 mg pluronic F127 (PF127) were dissolved in 5 mL dichloromethane as the oil phase (O). Freshly prepare 0.5 mL of ammonium bicarbonate (AB) aqueous solution of different concentrations as the water phase (W), and mix the two with a cell disruptor for ultrasonic emulsification for 1 min (power 200W, ultrasound 1s, interval 1s) to form a water-in-oil emulsion. The prepared water-in-oil emulsion is immediately loaded into a syringe, electrosprayed into an anhydrous ethanol solution through a high-pressure microcapsule forming device and a syringe pump, and is precipitated and solidified due to an anti-solvent process. The process parameters are: voltage 10kV, advancing speed 50mm / h, 26G needle (inner diameter 0.24mm), receiving di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com