Heat insulating device of isothermal thermal forming forging press

A heat preservation device and warm forming technology, which is applied in the field of forging machinery, can solve the problems of affecting work efficiency, increasing the difficulty of forging, wasting energy, etc., and achieve the effects of improving production efficiency, reducing processing costs, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

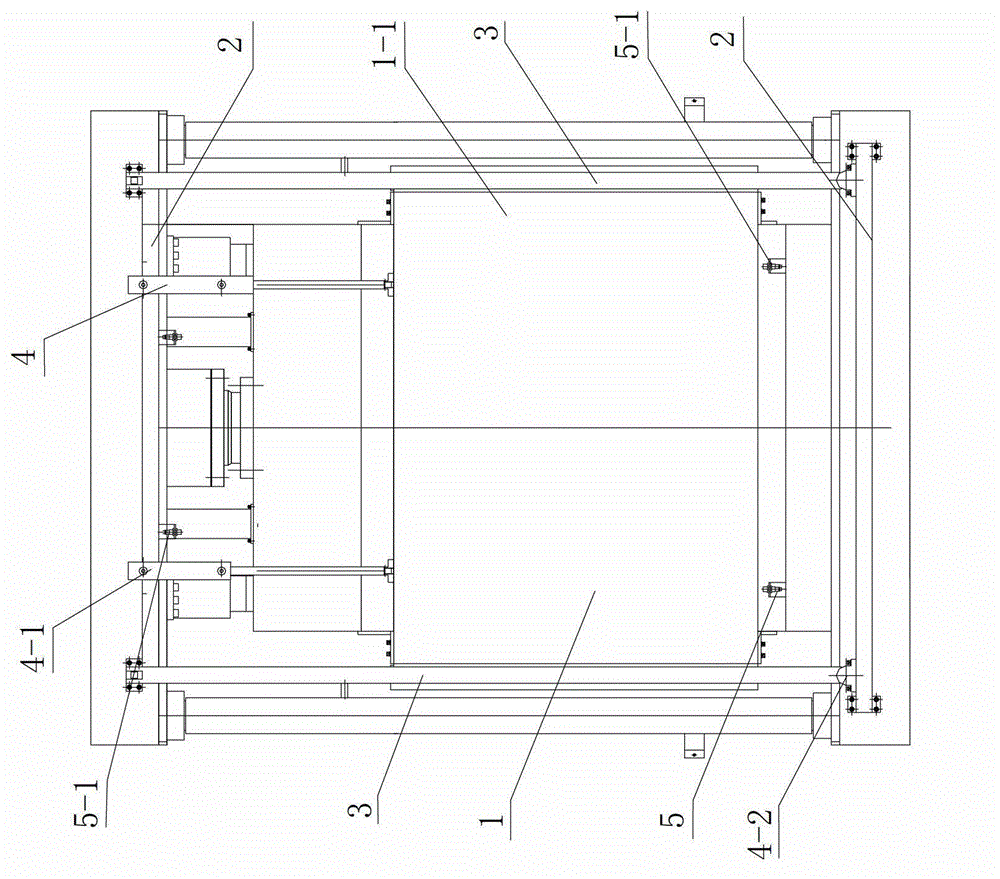

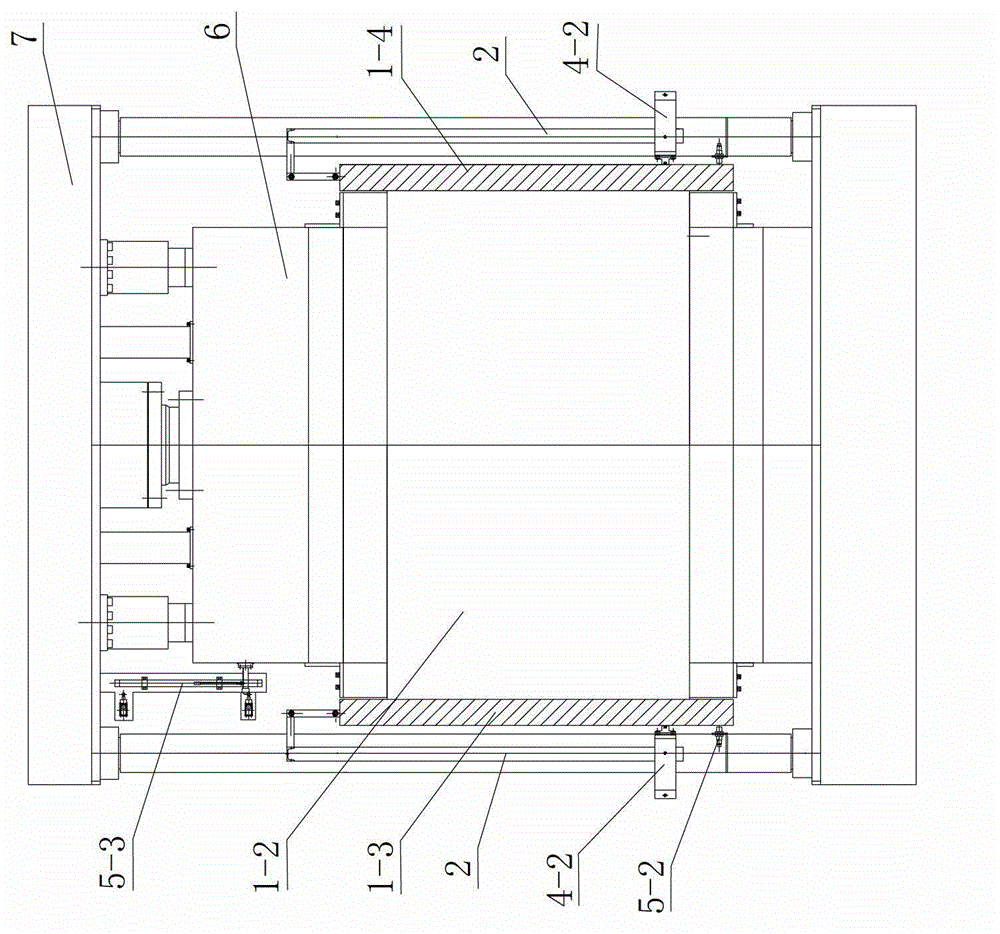

[0019] see figure 1 and figure 2 , isothermal thermoforming forging press insulation device, including forging press main body 7 and slider 6, also includes furnace door 1, furnace door bracket 2, driving mechanism 4 for driving the furnace door to move and for detecting the slider and furnace door The sender of the mobile location 5. The furnace door bracket is fixed to the main body of the forging press, and the furnace doors are distributed around the main body of the forging press, and are respectively connected to the furnace door brackets through hinges. One end of the driving mechanism is fixedly connected to the furnace door bracket, and the other end is fixed to the furnace door. The sending mechanism is respectively installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com