Heating plate for wire drawing machine

A wire drawing machine and heating plate technology, which is applied in the field of plastic processing machinery parts, can solve the problems of wasting electric energy and easily causing electric shock accidents, and achieve the effect of utilizing waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

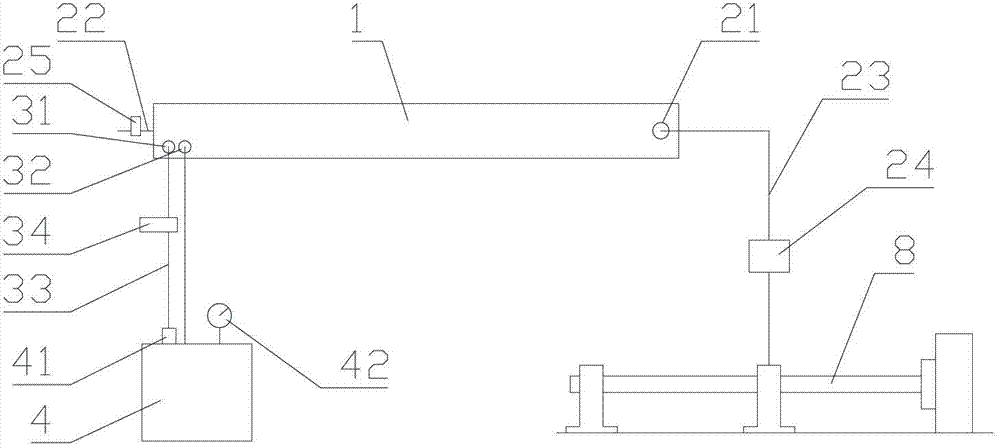

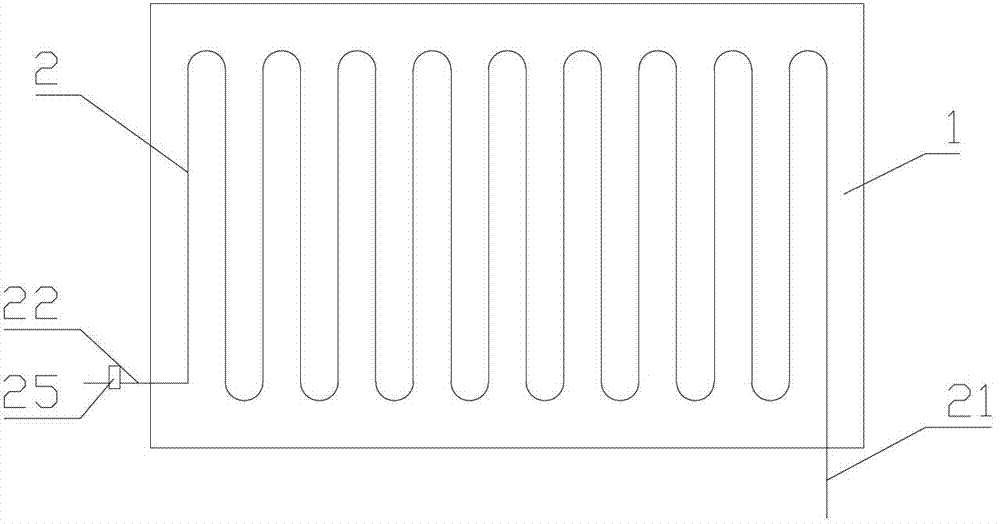

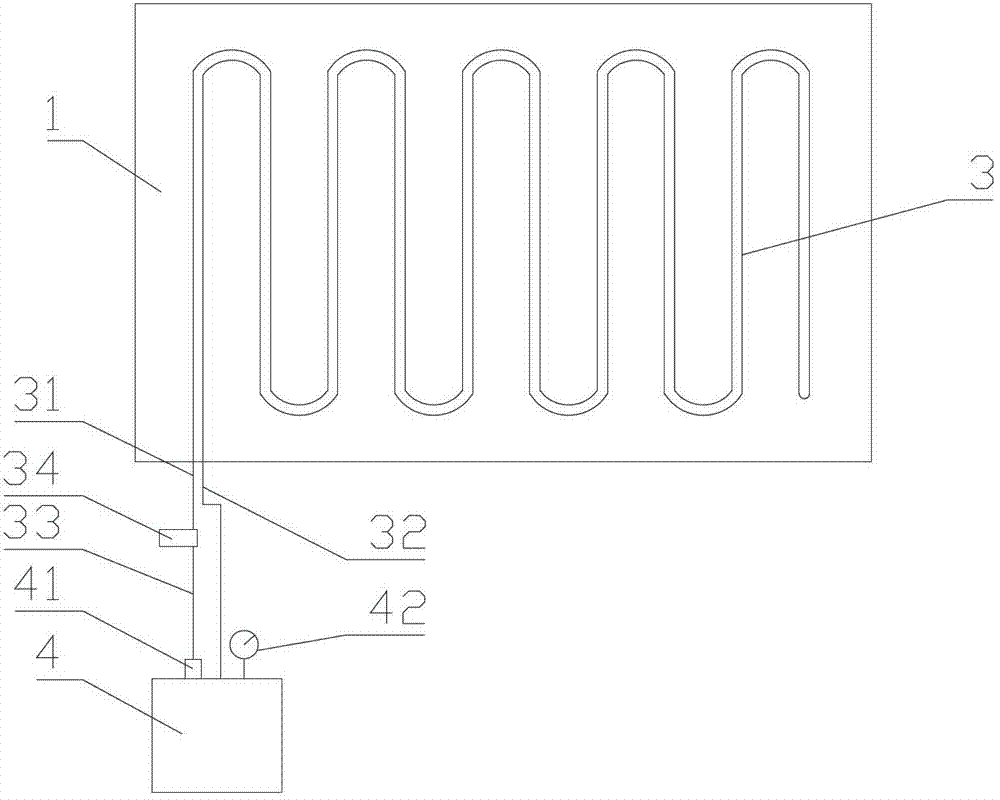

[0019] like Figures 1 to 3 Shown is an embodiment of the present invention, a heating plate for a wire drawing machine, including a plate body 1, a heating pipe 2 is arranged in the plate body, and an air inlet 21 of the heating pipe is arranged at one end of the plate body and is connected to the heating plate body. The inner cavity of the vacuum screw 8 in the heating tube is communicated, and the hot gas in the vacuum screw is passed into the heating tube, and the gas outlet 22 of the heating tube is arranged at the other end of the plate body, and the hot gas in the inner cavity of the vacuum screw in heating The temperature can reach 150 degrees, which is enough to heat the heating plate. Through the utilization of waste heat, the goal of energy saving and emission reduction in industrial production can be achieved, which is safe and environmentally friendly. Preferably, the heating pipes are arranged in an S shape or an inverted S shape to speed up heat transfer. Here,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com