A double-layer flexible cover

A flexible cover, double-layer technology, applied in layered products, rubber layered products, closures, etc., can solve the problems of not meeting the needs of use, anti-skid, poor burst resistance, etc., and achieve simple structure and good burst resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

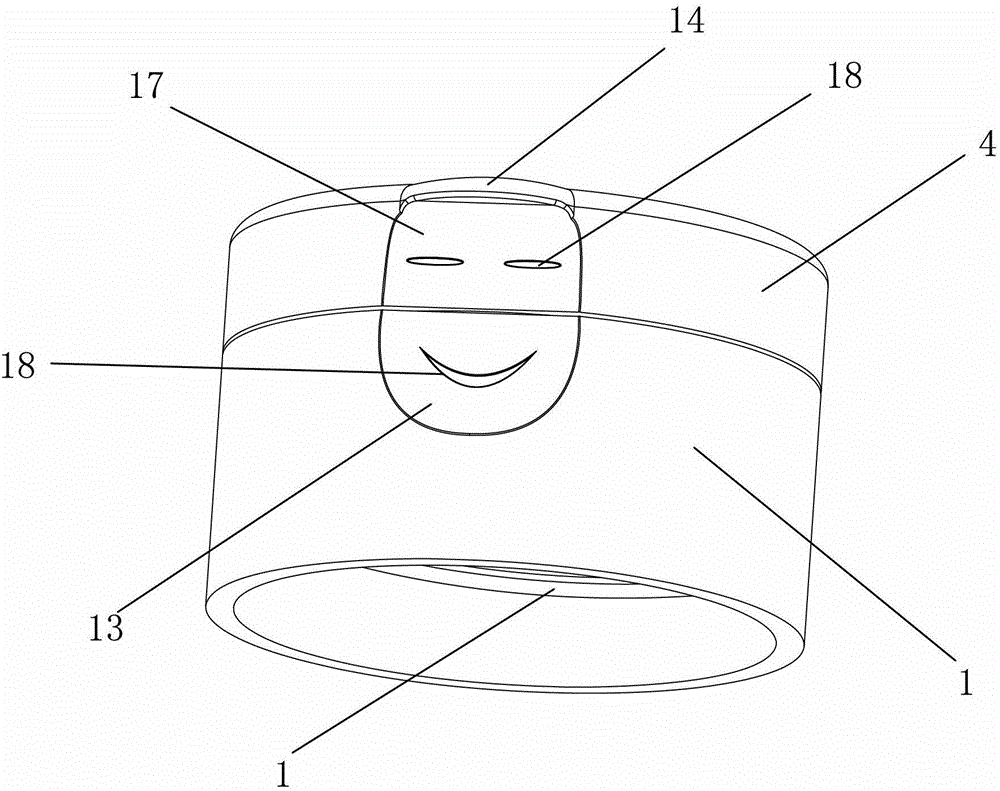

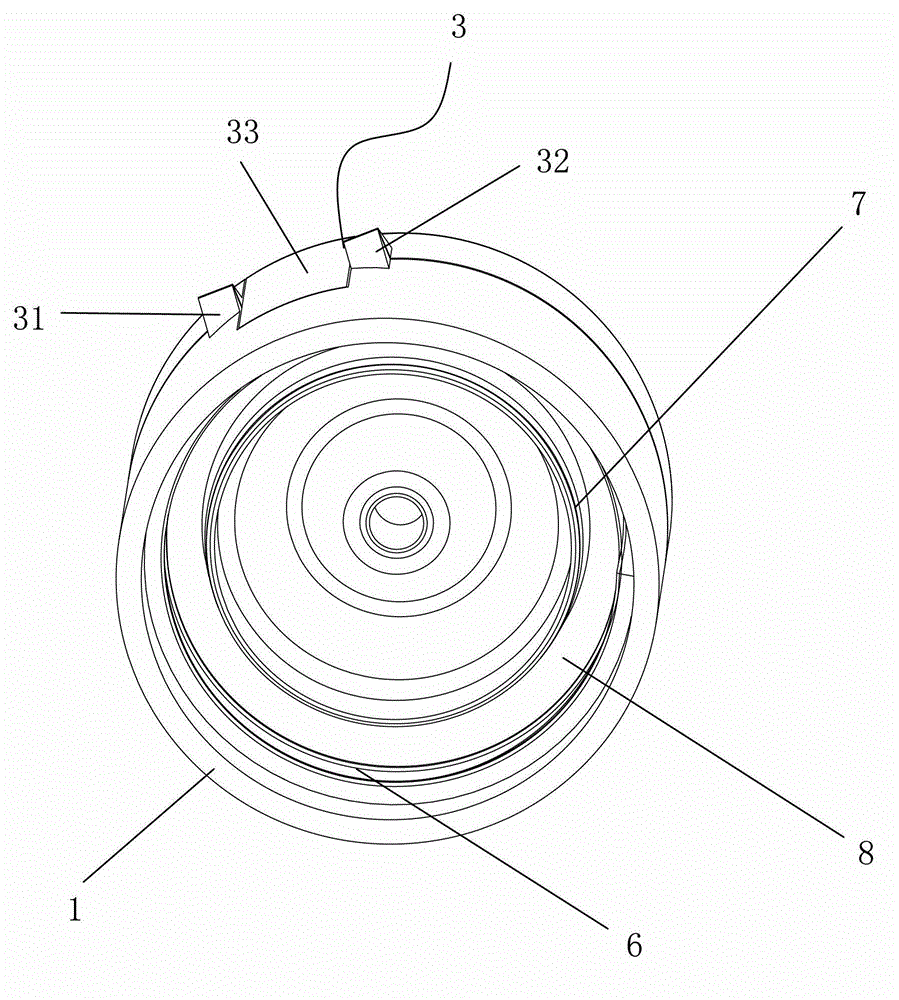

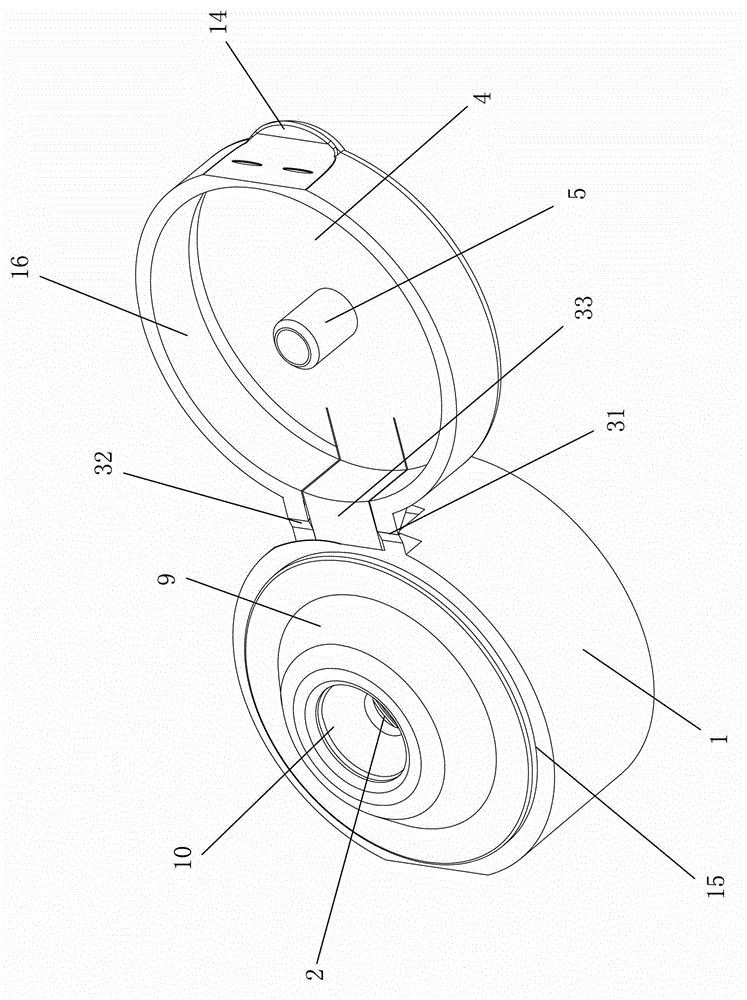

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0022] like Figures 1 to 5 The shown double-layer flexible cover includes a cover body base 1, the cover body base 1 includes a base body 11, and a non-slip and damage-resistant rubber outer layer 12 is injection-molded on the base body 11. The upper end of the cover base 1 is provided with an opening 2, and the cover base 1 is connected with a cover 4 that can be turned over and opened through a hinge assembly 3.

[0023] In the present invention, the cover body 4 is provided with a top post 5, the top post 5 is inserted into the opening 2, and the cover body base 1 is provided with an external connection with the opening of the bottle body 100. Threaded connection with internal thread 6.

[0024] In the present invention, a downwardly extending convex ring 7 is arranged in the cover base 1, a connecting groove 8 is provided between the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com