Single-floor masonry residential building steel-frame canopy guard structure and construction method thereof

A construction method and masonry technology, applied in building construction, protective buildings/shelters, building maintenance, etc., can solve problems such as poor vertical bearing capacity and horizontal seismic capacity, no seismic resistance, and overall collapse, etc. Low cost, simple structure and clear force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

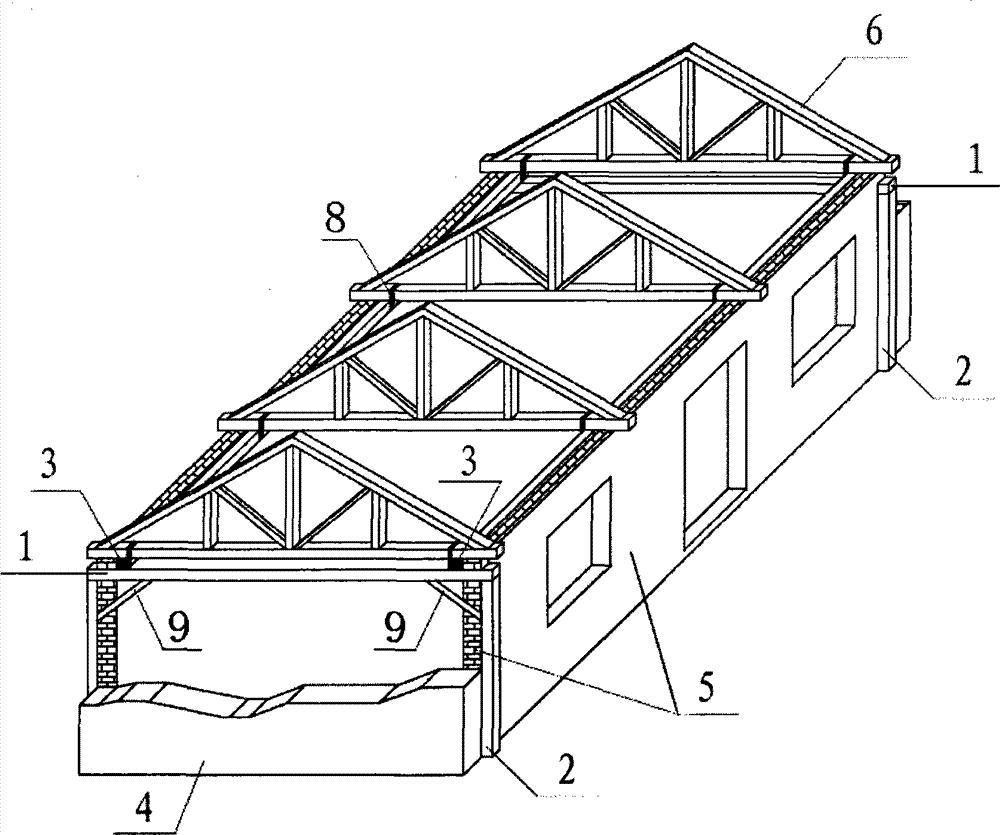

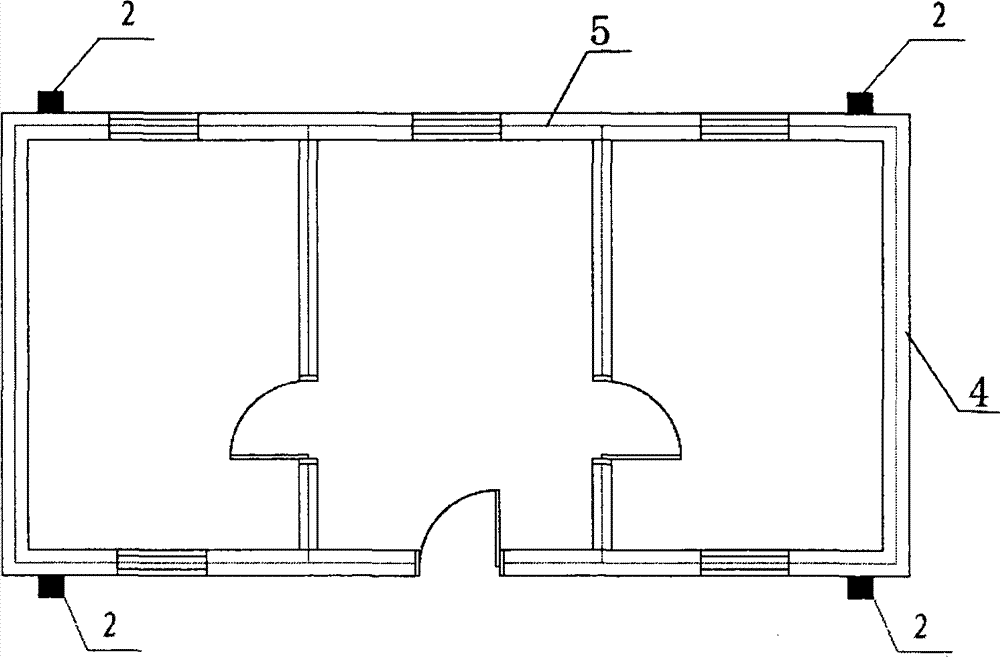

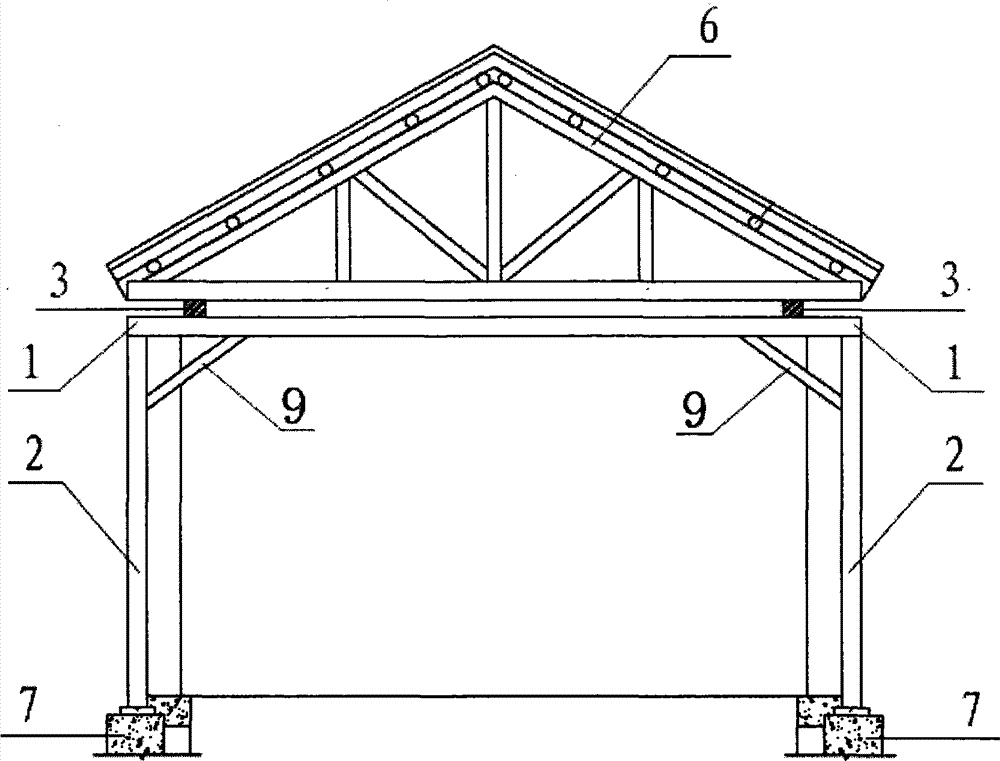

[0032] Such as Figure 1-4 As shown, a steel frame roof protection structure for a single-story masonry house, the single-story masonry house is provided with an original roof truss 6, and a reinforced steel frame is installed on the bottom surface of the original roof truss 6, and the reinforced steel frame is composed of at least two external horizontal Steel beams 1, two additional longitudinal steel beams 3, four additional steel columns 2 and an additional foundation 7, the additional longitudinal steel beams 3 are inside the original longitudinal wall 5, and the additional transverse steel beams 1 are arranged outside the original gable wall 4, The ends of the added longitudinal steel beams 3 rest on the added transverse steel beams 1, and the two are fixedly connected to form the same outline as the original structure plane shape, and the added steel columns 2 are close to the original gable 4 or the original longitudinal wall 5, the top end is supported on the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com