Lifting-free borehole bottom rope freezing coring drilling tool and method

A core drilling tool and drilling bottom technology, applied in the direction of extracting the undisturbed core device, earthwork drilling and mining, etc., can solve the problems of inability to fully utilize liquid nitrogen, waste of man-hours, and failure of coring, so as to improve drilling efficiency, Save man-hours and enhance the freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

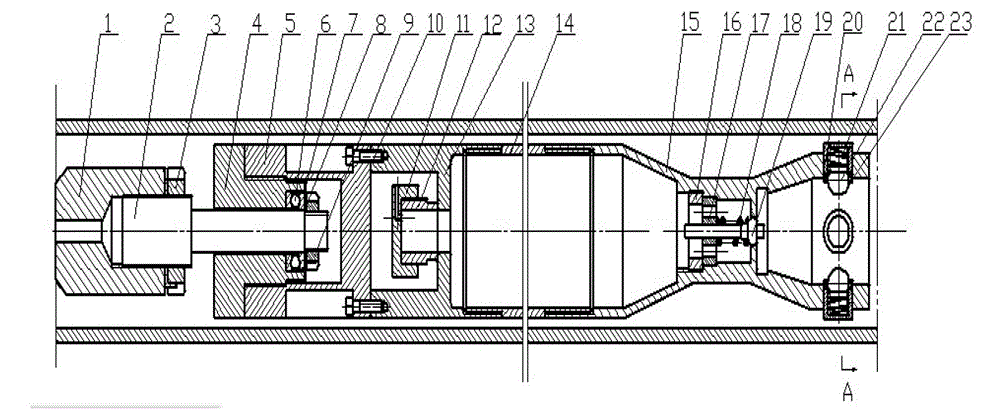

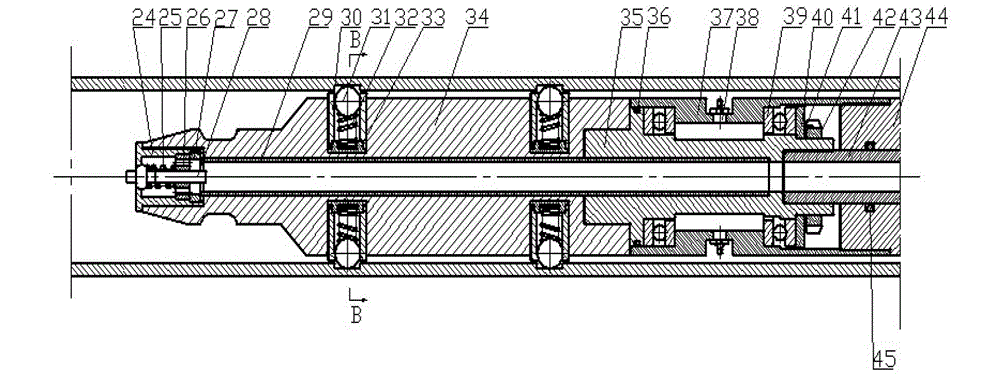

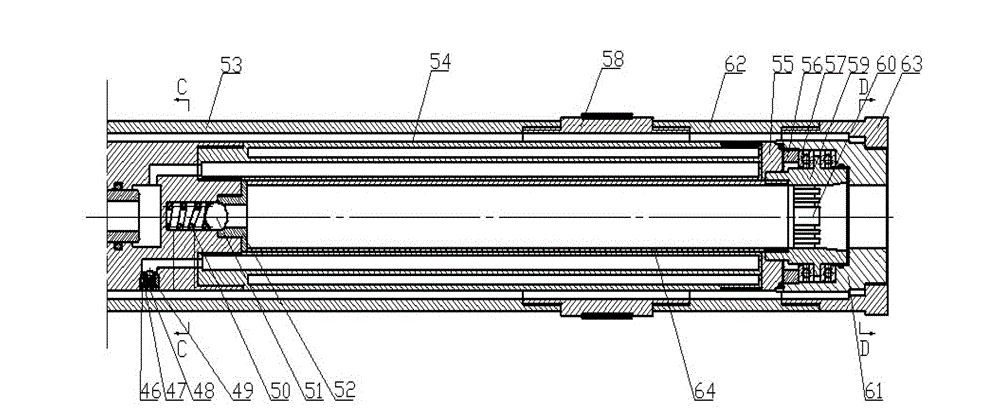

[0030] The drilling tool is composed of three parts, which are the overshot, the inner pipe assembly and the outer pipe assembly. When drilling, the ordinary core drilling Take out the pipe assembly, put it into the inner pipe assembly of the frozen wireline coring tool at the bottom of the borehole, and drill together with the small drill bit 61 on the inner pipe assembly and the large drill bit 63 on the outer pipe assembly to obtain the hydrate core; After the completion of the round, put in the overshot that does not lift the frozen rope core drilling tool at the bottom of the drilling hole, inject the liquid nitrogen in the overshot into the core tube to freeze the core, and then use the overshot to salvage the inner tube assembly to the surface to obtain the hydrate core .

[0031] The liquid nitrogen used in the frozen hydrate core in the present invention is stored in the overshot, and after the return is completed, it is put into the hole and connected with the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com