Laser positioning detection system of automatic ship mooring system

A mooring system and laser positioning technology, applied in the field of ships, can solve problems such as insufficient detection margin, achieve the effects of reducing damage and loss, protecting system safety, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

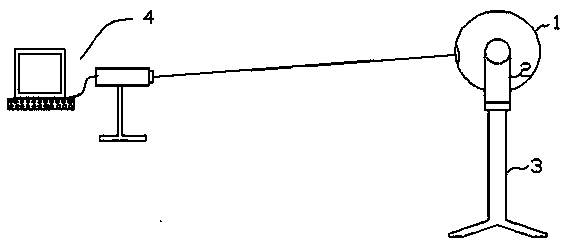

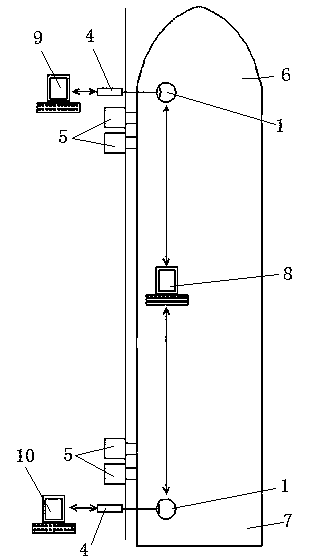

[0013] like figure 1 and image 3 As shown, the present invention includes a laser beam analyzer 4 and a laser processor 1, wherein the laser beam analyzer 4 is fixedly installed on both sides of the automatic mooring system 5 of the bow 6 and the stern 7 along the wharf, and the two laser beams The spatial position of the analyzer 4 corresponds to the two laser processors 1 installed on the bow and stern respectively.

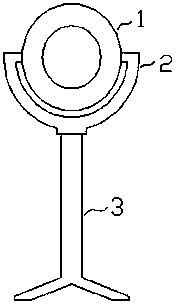

[0014] like figure 2 As shown, the laser processor 1 is an assembled instrument including a laser transmitter and receiver and a precision stopwatch. By emitting laser light and receiving diffusely reflected laser light, it measures the time of laser emission and return. Its shell is designed as a circle with a middle opening There are round holes on the left and right sides of the laser emission hole, through which the arc bracket 2 is hinged, so that the laser processor 1 can swing up and down 360 degrees around the arc bracket 2. The base of the arc brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com