Plate type heat exchanger having outer heat exchanger plates with improved connections to end panels

A plate heat exchanger, heat exchange plate technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve problems such as being prone to errors, increasing production costs and maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

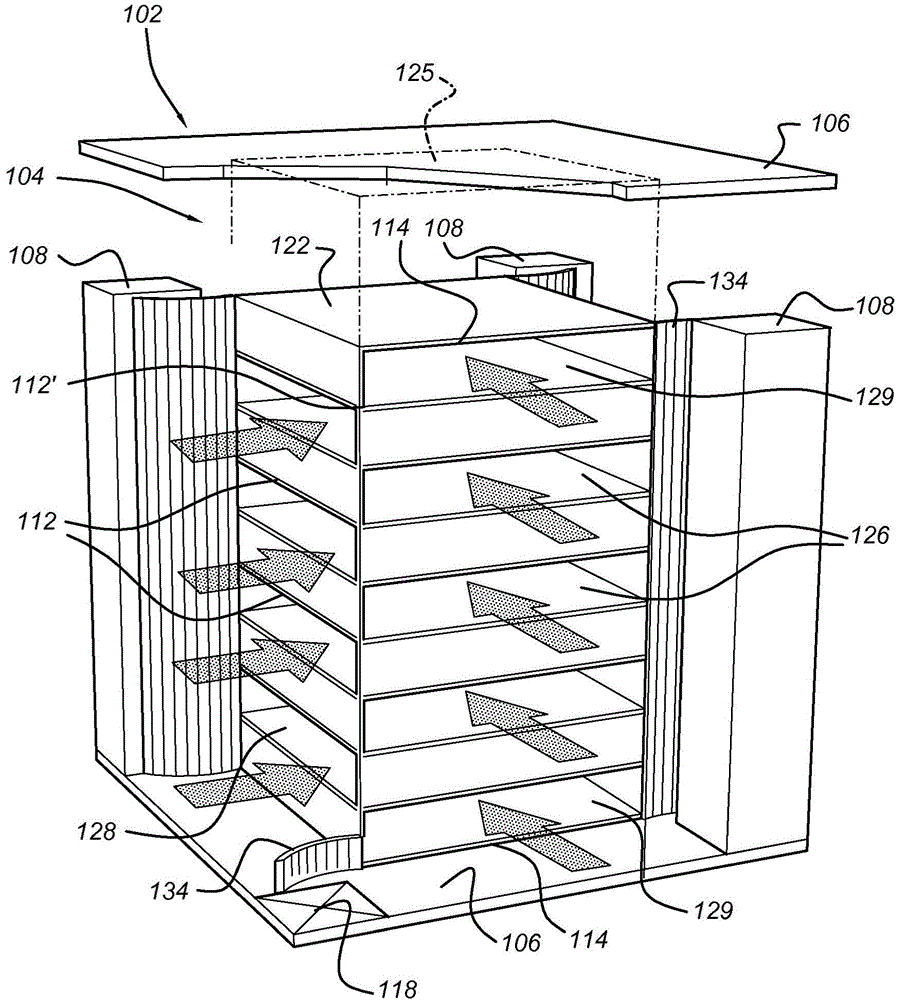

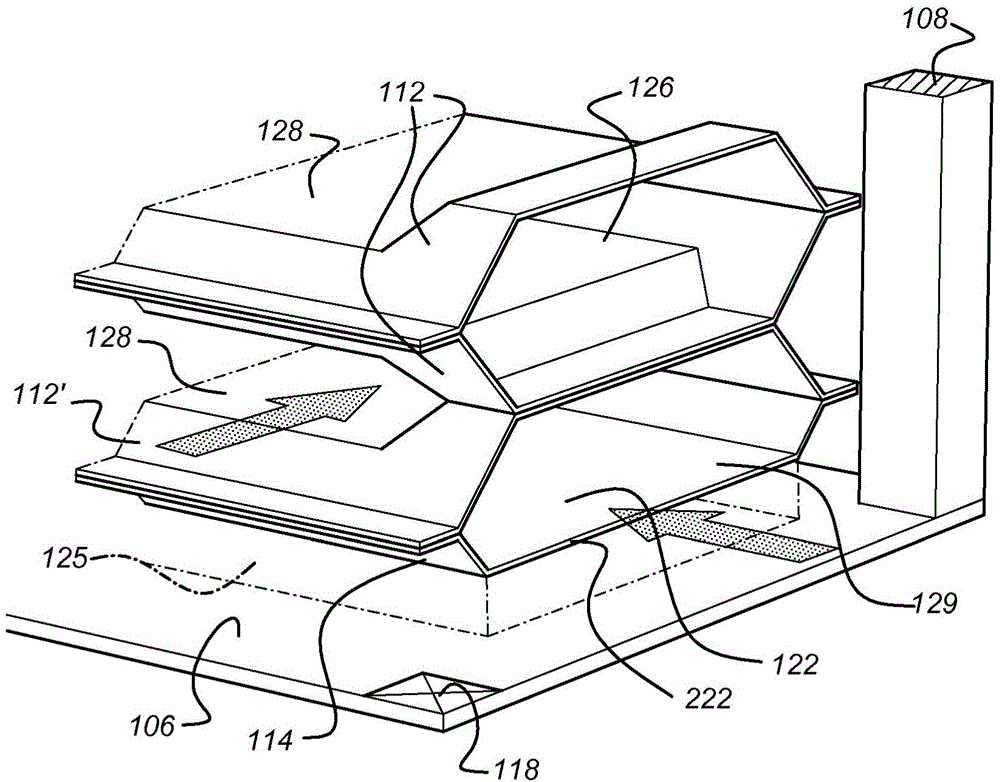

[0018] figure 1 A perspective view of one embodiment of a plate heat exchanger 102 is schematically shown. The plate heat exchanger 102 includes a heat exchanger assembly 104 , end plates 106 , and end plate connectors 107 connecting the end plates 106 . In general, end plate connectors 107 may be provided to connect end plates 106 in multiple regions of end plates 106 . exist figure 1 In the embodiment, the end plate connector 107 includes an angle beam 108 connected to the end plate 106 in the angle beam connection area 118 .

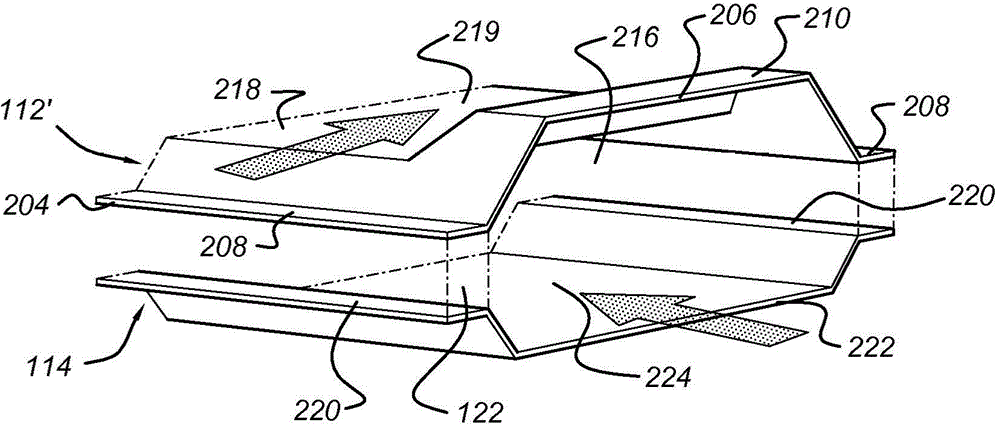

[0019] The heat exchanger assembly 104 includes a set of heat exchange plates 112 and a pair of outer heat exchange plates 114 on opposite sides of the heat exchanger assembly 104 . Heat exchange plate 112 and outer heat exchange plate 114 are shown in a spaced apart and parallel configuration.

[0020] Also shown is end plate 106 , which is located near the opposite side of heat exchanger assembly 104 . The end plates 106 are shown parallel to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com