rGO-LiOH micro-spring/wood composite electrode material and preparation method and application thereof

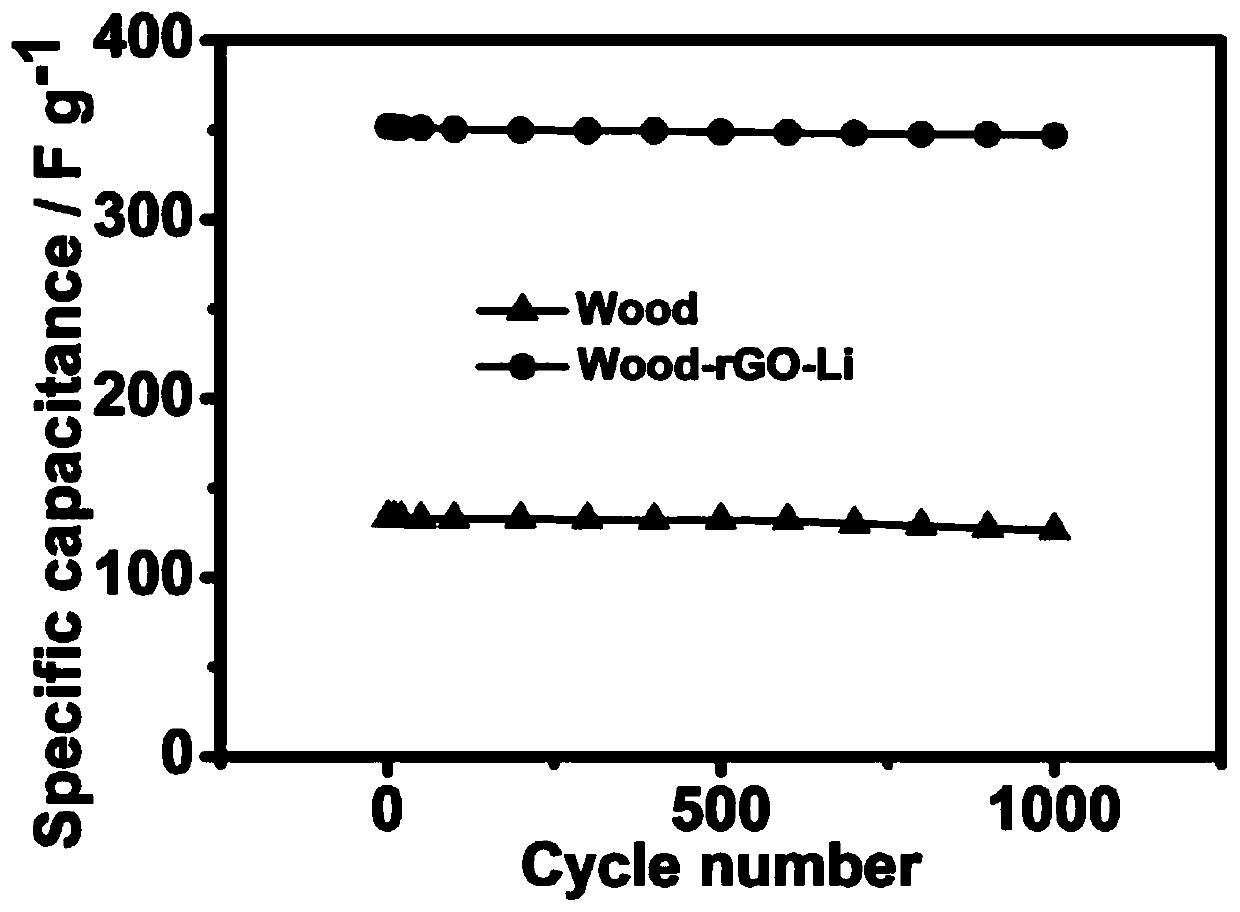

A composite electrode and micro-spring technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems that have not been reported, and achieve the effects of reducing internal resistance, high specific capacitance, and increasing load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

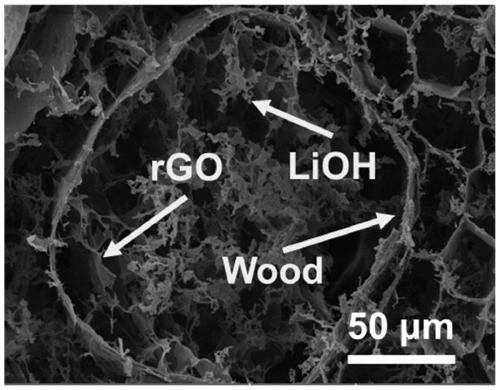

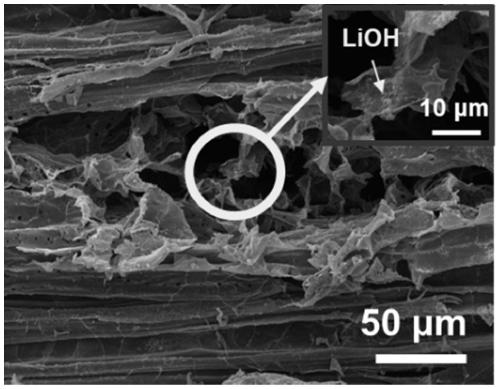

[0035] A kind of preparation method of the elastic electrode material that the rGO-LiOH micro-spring of the present invention is a kind of 3D and wood compound comprises the following steps:

[0036] Step 1, prepare 100ml of 1-3mol / L lithium carbonate solution, take 0.1-0.5g of self-made graphene oxide, add 50-300ml of deionized water and disperse it with an ultrasonic cell pulverizer for 10-30min, at -50--5℃ freeze-dried for 2-4 hours to obtain LiCO 3 and GO airgel;

[0037] Ultrasonic cell pulverizer fully mixes graphene oxide and lithium carbonate, and pulverizes large pieces of graphene oxide so that it can enter wood pores; working frequency is 20-24KHz, ultrasonic power is 200-600W, temperature: 25-40°C ;

[0038] Step 2, the LiCO 3 Put the airgel with GO into a tube furnace for temperature programming, and raise the temperature to 130-300°C in the air at room temperature at a rate of 2-15°C / min for 2-4 hours to remove moisture;

[0039] Then raise the temperature to...

Embodiment 1

[0047] A kind of 3D rGO-LiOH miniature spring of the present invention and the preparation method of the composite elastic electrode material of wood comprise the following steps,

[0048] Step 1, prepare 150ml of 1mol / L lithium carbonate solution, take 0.1g of self-made graphene oxide, add them to 50ml of deionized water, disperse with ultrasonic cell pulverizer for 30min, and freeze-dry at -50°C for 3h to obtain LiCO 3 and GO airgel;

[0049] The working frequency of the ultrasonic cell pulverizer is 20KHz, the ultrasonic power is 300W, and the temperature is 30°C;

[0050] Step 2, the LiCO 3 Put the aerogel with GO into a tube furnace, heat up the temperature program, keep it at room temperature at 5°C / min to 150°C for 2 hours, and then keep it at 10°C / min to 1000°C for 2 hours. After the temperature drops to room temperature, take out the material and place it in a dry place. In the device, the rGO microspring supported by LiOH is obtained;

[0051] Step 3, cut a wood c...

Embodiment 2

[0055] A kind of 3D rGO-LiOH miniature spring of the present invention and the preparation method of the composite elastic electrode material of wood comprise the following steps,

[0056] Step 1, prepare 200ml of 1.5mol / L lithium carbonate solution, take 0.15g of self-made graphene oxide, add them to 50ml of deionized water, disperse them with an ultrasonic cell pulverizer for 20min, and freeze-dry them at -20°C for 4h to obtain LiCO 3 and GO airgel;

[0057] The working frequency of the ultrasonic cell pulverizer is 22KHz, the ultrasonic power is 250W, and the temperature is 32°C;

[0058] Step 2, the LiCO 3 The airgel with GO was put into a tube furnace, and the temperature was raised by program. The temperature was kept at 7°C / min to 180°C for 4 hours, and then kept at 15°C / min to 1100°C for 2.5 hours. After the temperature dropped to room temperature, the material was taken out and placed in a In the desiccator, the rGO microspring supported by LiOH is obtained;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com