Block body for connecting cable protection pipe, and connecting structure of cable protection pipe

A technology for protecting tubes and connecting cables, which is used in cable installation, cable installation in cable rooms, and cable laying equipment. High, simple and reliable connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

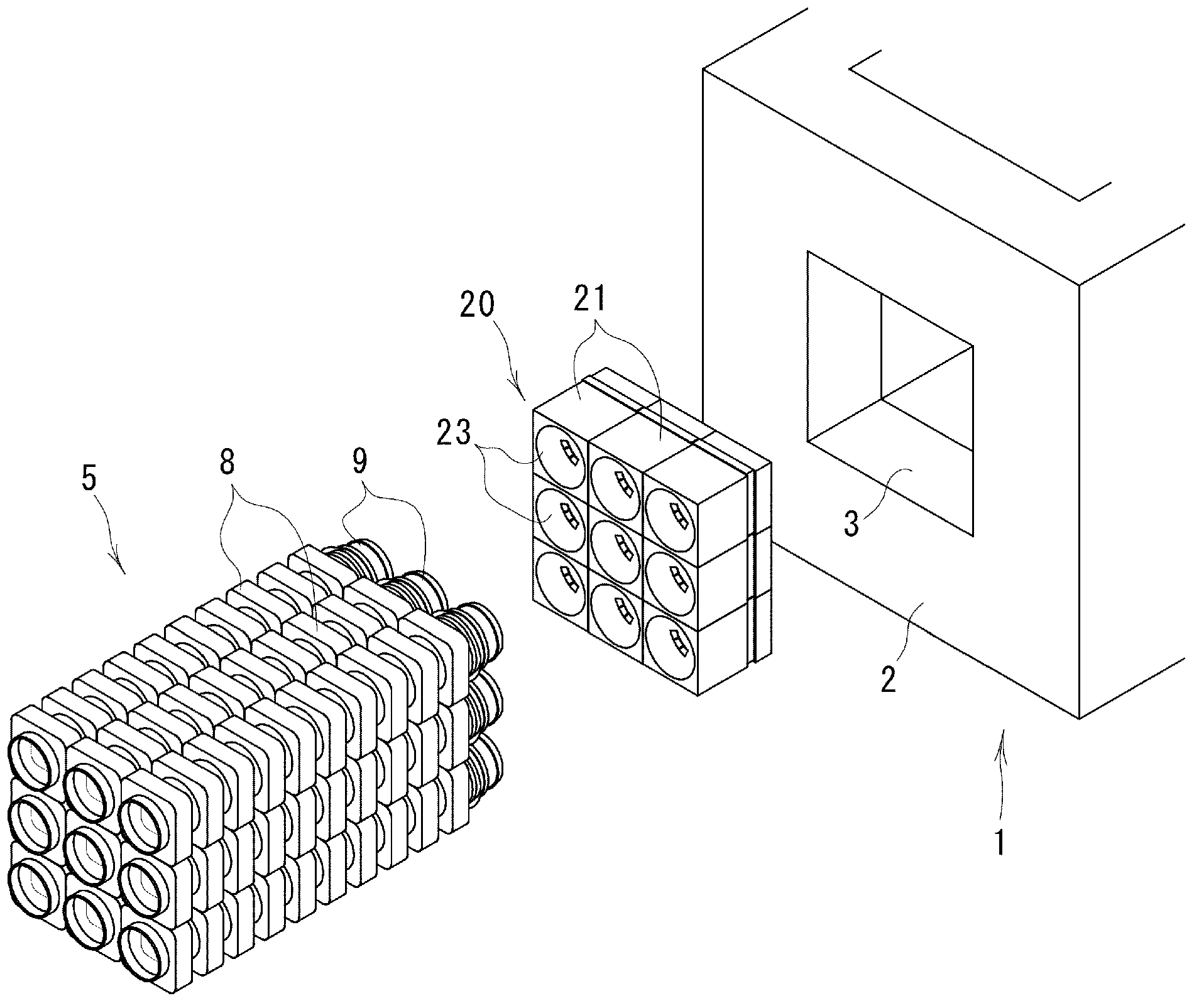

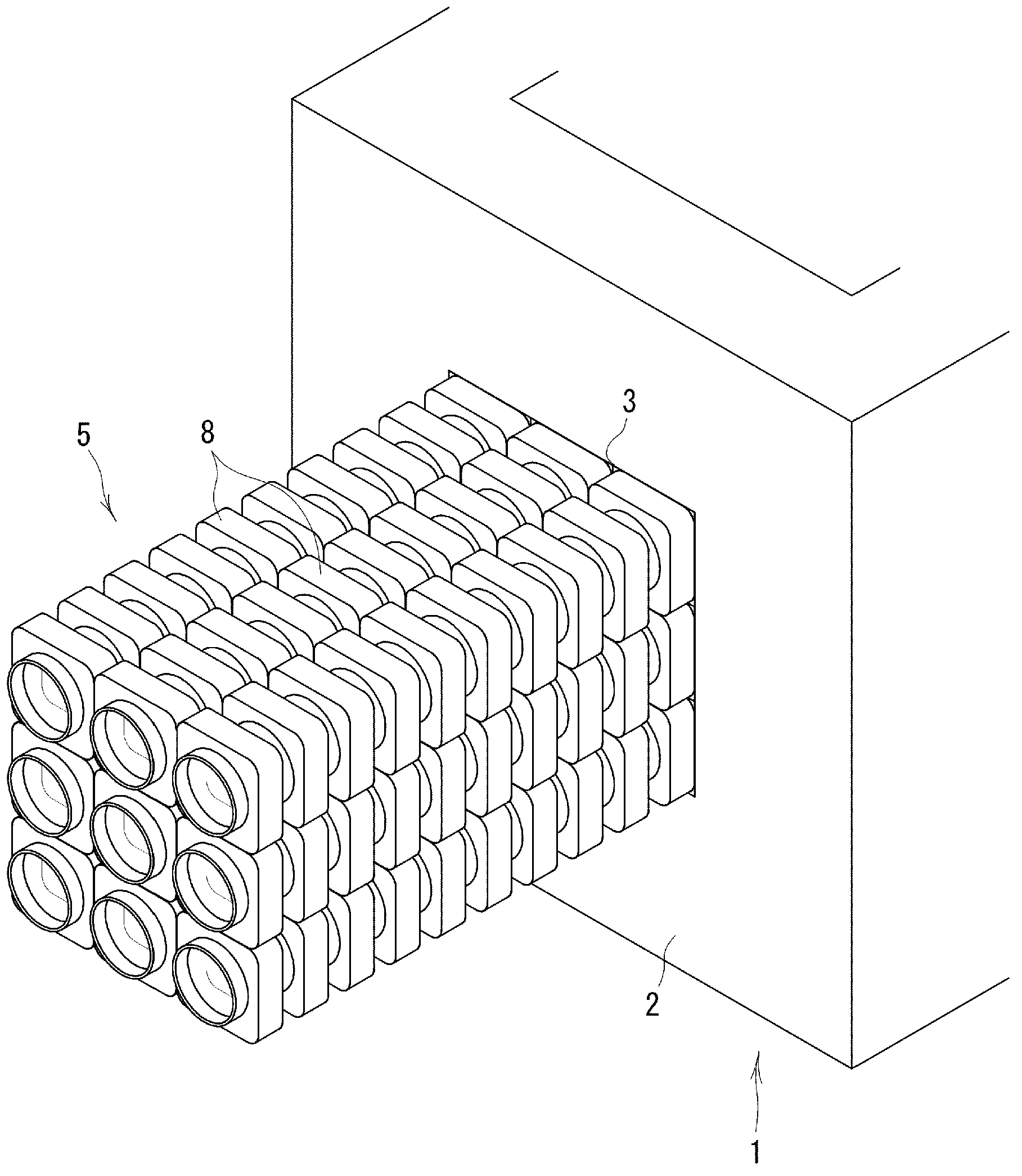

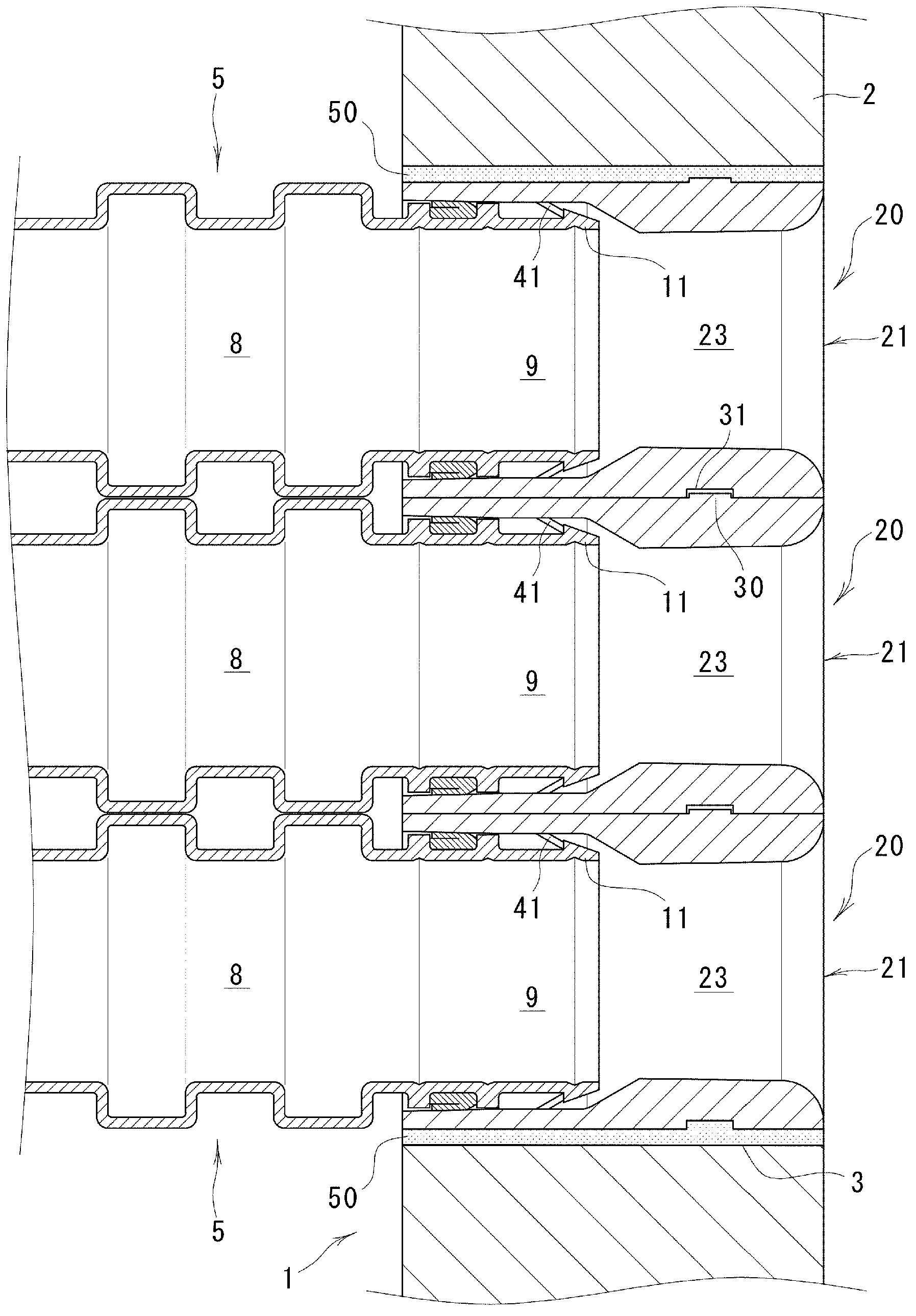

[0045] Hereinafter, embodiments of the present invention will be described in detail based on the drawings. Figure 1 to Figure 3 The connection structure of the cable protection tube which concerns on one Embodiment of this invention is shown. In the figure, 1 is a hand hole (including a man hole) made of concrete or resin concrete, and a square-shaped through-hole portion 3 is formed on the side wall 2 thereof.

[0046] Reference numeral 5 denotes a synthetic resin cable protection tube formed, for example, by blow molding, which is embedded in the ground and cables such as electric wires and optical fiber cables are inserted therein. Such as Figure 4 and Figure 5 As shown, the cable protection tube 5 has a tube wall 8, and the tube wall 8 alternately has protrusions 6 with a tube radial section in a substantially square shape along the tube axial direction and a tube radial section with a roughly square shape. Circular recess 7 . . . Furthermore, a male adapter 9 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com