Homopolar motor phase

A unipolar motor, yoke technology, applied in unipolar motors, electrical components, electromechanical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

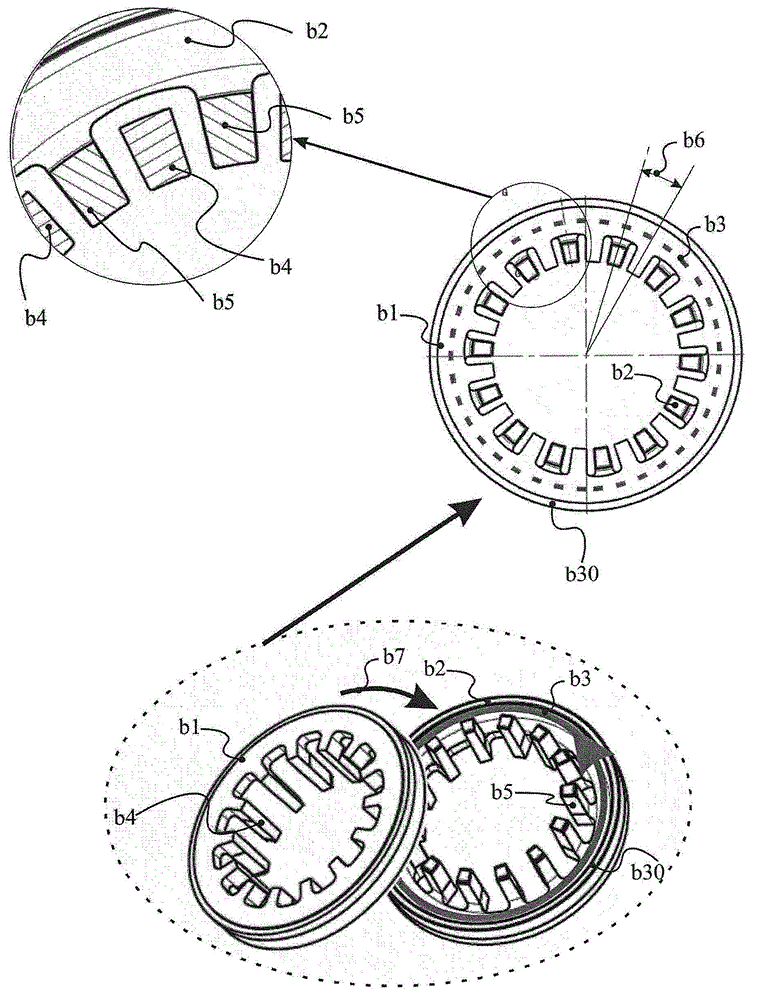

[0046] exist Image 6 The above invention shows a specific embodiment of a tooth formed by its tooth foot ( a5 ) and its tooth leg ( a3 ), which redirects the magnetic flux between two consecutive teeth ( a3 ) in the connecting surface, so that it takes a magnetic path other than the radial direction. This results in a corresponding increase in the copper cross section available for the winding ( b3 ).

[0047] exist Image 6 In the implementation, with the Figure 5 In the same manner as above, the magnetic flux Fd (a2) returns through the foot (a5) of each tooth. However, since the space (a6) existing between two consecutive tooth legs (a3) of the tooth is filled with magnetic material, instead of Figure 5 The vacuum that exists on the surface, before reaching the opposite tooth (a5a) through the winding magnetic circuit, the magnetic flux Fd (a2) is divided into two magnetic fluxes Fc (a1), passing through the latter inter-tooth space (a6), subordinate to the phase (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com