Arrangement structure and fire extinguishing method of large-size high-expansion foam fire extinguishing system

A foam fire extinguishing and high-power technology, which is applied in fire rescue and other fields, can solve the problems of easy failure of foam stock solution, unreasonable design scheme, and improvement, so as to achieve the effect of not being easy to be corrupted and deteriorated, meeting the requirements of international standards, and reducing the amount of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

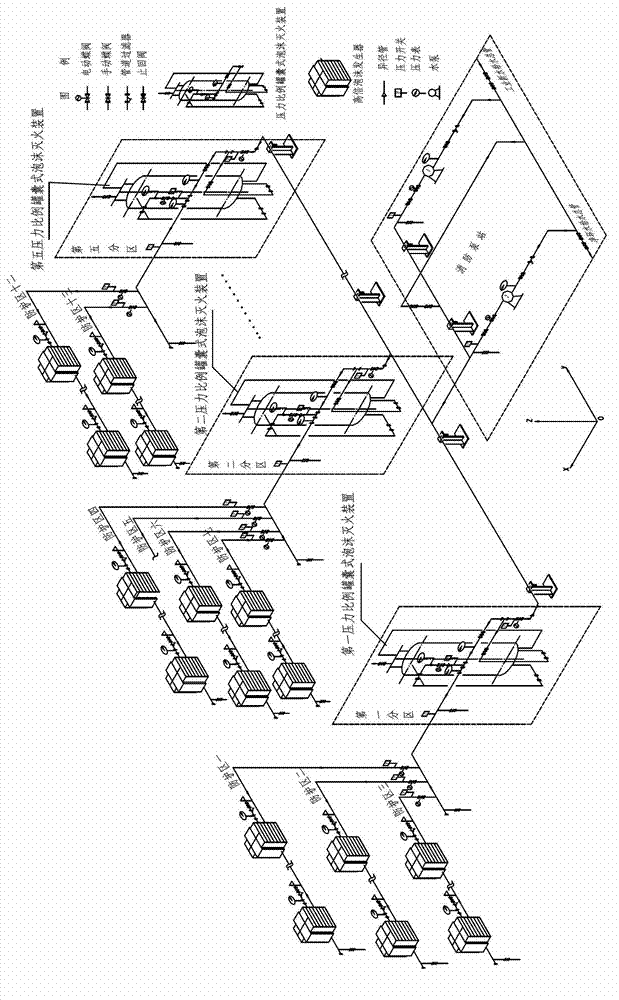

[0016] See figure 1 , which is a structural schematic diagram of an embodiment of the layout structure of the large-scale high-expansion foam fire extinguishing system of the present invention. The protected area under its jurisdiction is divided into several partitions, and each partition adopts a centrally controlled fire pump station and fire control center; the fire pump station is equipped with a fire pump; A set of pressure proportional tank-type foam fire extinguishing device is installed in each partition (the device includes a storage tank, a diaphragm bag and a pressure proportional mixer, and the foam liquid is stored in the storage tank); The size of the protection area and the technological layout select two water conservancy-driven foam generators, PFS4 and PFS10, respectively; The delay time for starting to spray foam shall not exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com