Carbon dioxide catching device and method

A technology for carbon dioxide and capture devices, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems such as blockage, consumption of more energy, corrosion of pipelines or storage tanks, etc., to achieve the effect of improving the purity of capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

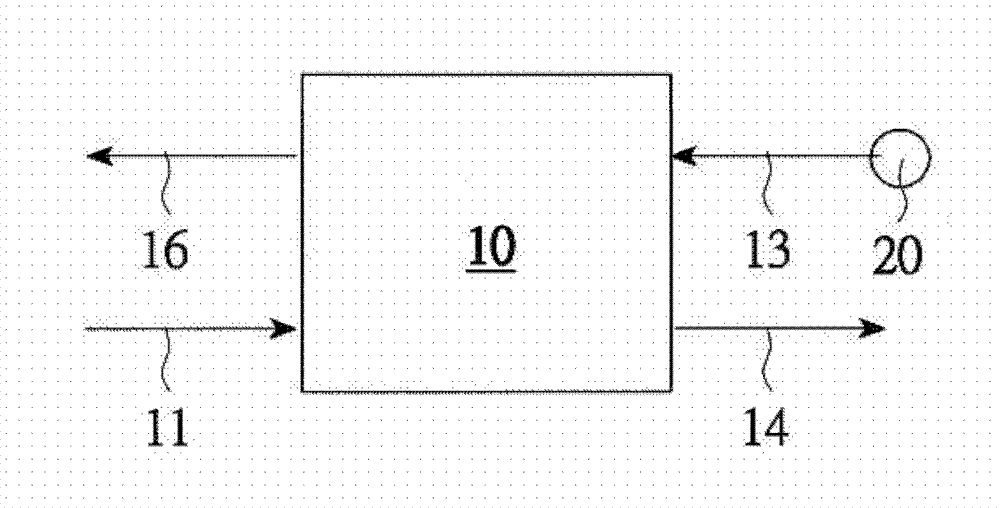

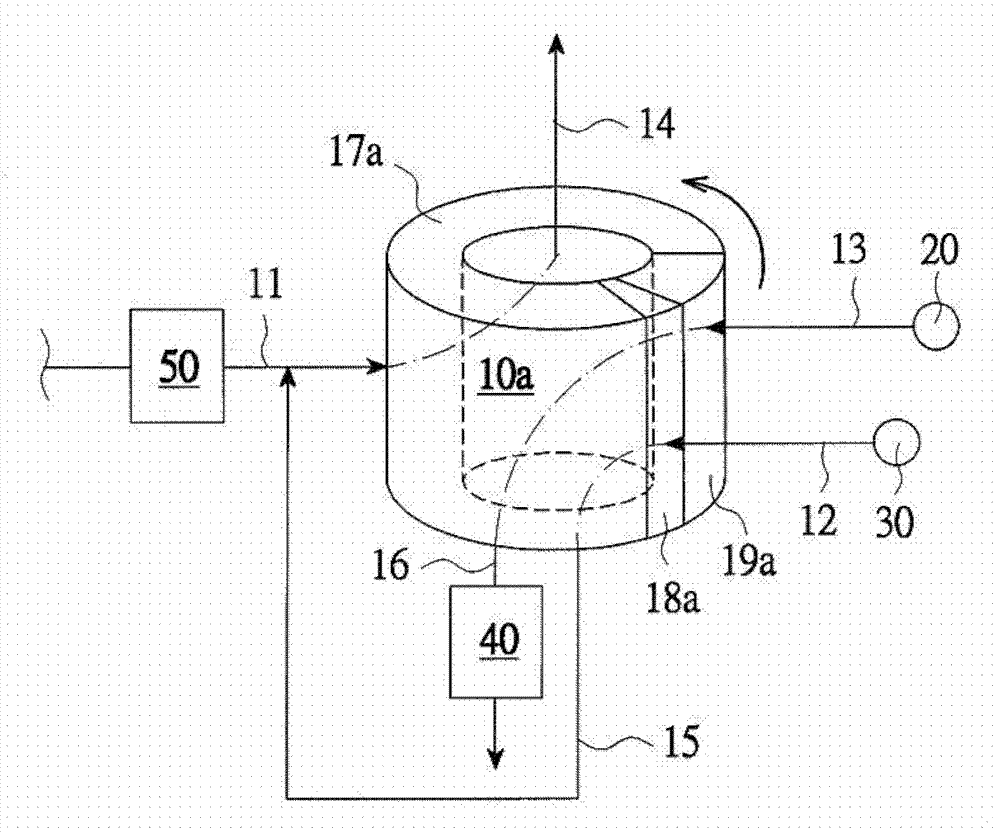

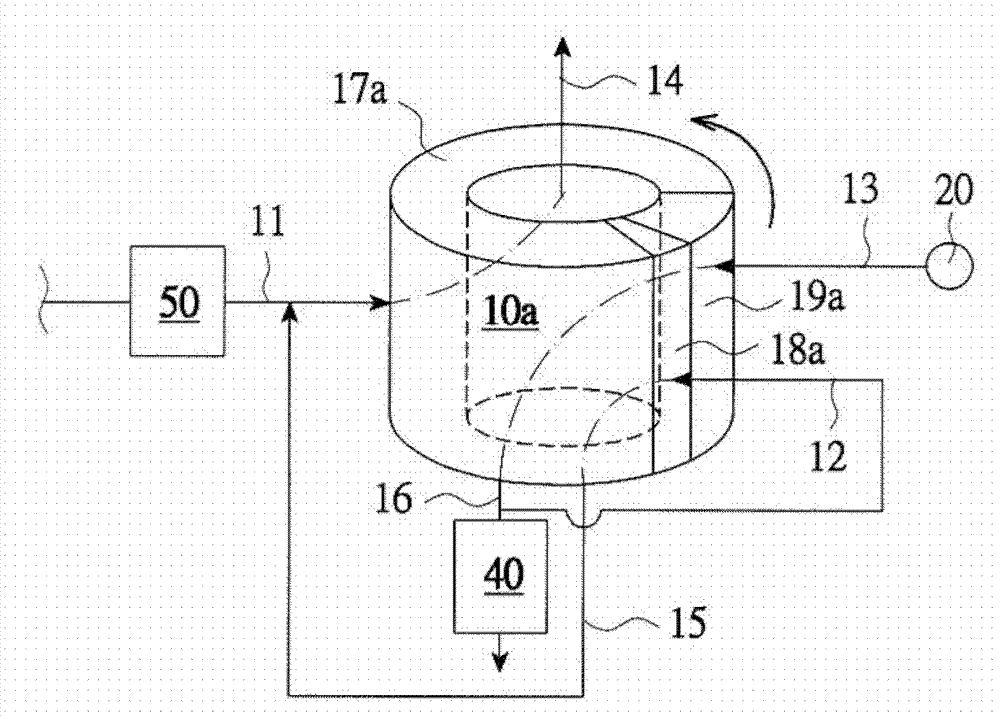

[0034] First, see Figure 2A , Figure 2B , Figure 2C As shown, the first embodiment of the present invention includes:

[0035] A swivel-type adsorption-desorber 10a has an adsorbent for absorbing carbon dioxide inside, and is externally connected with a gas flow input pipe 11 to be treated, a flushing gas flow input pipe 12, a desorption steam input pipe 13, and a treated gas flow output pipe. Pipe 14, an air flow output pipe 15 after flushing and a desorbed steam output pipe 16, and follow the direction of rotation to separate the adsorption area 17a, the washing area 18a and the desorption area 19a, and make the air flow to be treated input pipe 11 The treated gas flow output pipe 14 is oppositely connected to both sides of the adsorption area 17a, the flushing air flow input pipe 12 is connected to the both sides of the flushing area 18a oppositely to the washed air flow output pipe 15, and the desorption steam input pipe 13 is connected to the The desorbed steam outp...

no. 4 example

[0051] Alternatively, see Figure 5A , Figure 5B , Figure 5C As shown, the fourth embodiment of the present invention includes:

[0052] A fluidized bed adsorption-desorber 10d has an adsorption material for absorbing carbon dioxide inside, and is an adsorption bed 101, a desorption bed 102, and a delivery pipeline for circulating the adsorption material between the adsorption bed 101 and the desorption bed 102 103, the lower and upper sides of the adsorption bed 101 are connected to a gas flow input pipe 11 to be treated and a gas flow output pipe 14 to be treated, and the lower and upper sides of the desorption bed 102 are connected to a flushing gas flow The input pipe 12 and a flushed air flow output pipe 15 and a desorption steam input pipe 13 and a desorption steam output pipe 16;

[0053] The flushing air inlet pipe 12 is connected to a flushing air supply source 30 (such as Figure 5A shown), and the flushing airflow supply source 30 supplies the flushing airflow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com