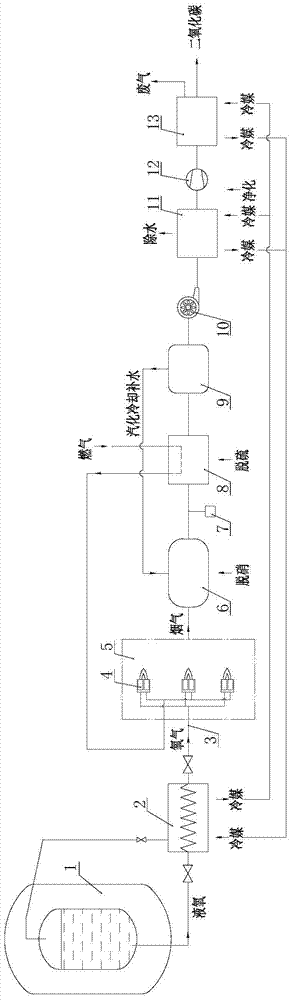

A heating furnace pure oxygen combustion and carbon dioxide capture system and process

A carbon dioxide, heating furnace technology, applied in lighting and heating equipment, process efficiency improvement, furnace and other directions, can solve the problems of difficult capture and high process energy consumption, and achieve the reduction of capture cost, noise pollution, and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0043] Transport the liquid oxygen storage tank from the gas company to the gas station near the heating furnace by tanker. The carburetor is fixedly installed in the gas station. The liquid oxygen storage tank and the vaporizer are connected by a liquid oxygen pipeline. The evaporator adopts a circulating refrigerant bath evaporator. The refrigerant is calcium chloride solution with a mass fraction of 29.4%. The operating pressure of the vaporizer is ≤0.4MPa. There are valves between the vaporizer, the liquid oxygen storage tank and the oxygen delivery pipeline to control the flow of liquid oxygen and oxygen. The liquid oxygen pipeline adopts low-temperature special valves.

[0044] The liquid oxygen in the liquid oxygen storage tank is vaporized into oxygen by the vaporizer. Oxygen enters the oxygen delivery pipeline at normal temperature. The valves of the oxygen delivery pipelines are special valves for oxygen at room temperature. The oxygen delivery main pipe is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com