Local dry-type underwater friction stitch welding device

A friction stitch welding and dry water technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of complex equipment, high cost, unsatisfactory welding quality, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

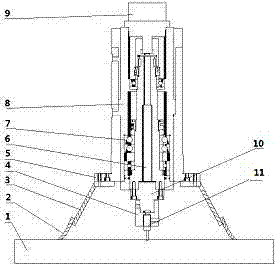

[0014] Depend on figure 1 It shows a partially dry underwater friction stitch welding device, in which: the sealing gasket 2 made of rubber material is connected to the cover body 3, and the cover body 3 is connected to the hydraulic cylinder body 5 through bolts, and the transmission shaft 6 passes through The coupling is connected to the hydraulic motor 9, and the hydraulic motor 9 is connected to the hydraulic cylinder body 5 through bolts. The transmission shaft 6 and the hydraulic cylinder piston 8 are positioned by the support bearing 7, and the distance between the spindle housing and the workpiece 1 can be adjusted. Small adjustments.

[0015] Before welding starts, position the device at a reasonable height to ensure a certain seal between the gasket 2 and the workpiece 1, and then discharge the water by filling the cover 3 with high-pressure gas to form a stable local dry welding environment. At the same time, it plays a role of gas protection for the welding proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com