Frame combination tooling of semitrailer and manufacturing method thereof

A semi-trailer and frame technology, which is applied in the field of semi-trailer frame assembly tooling and its manufacturing, can solve the problems of easy errors, low precision, cumbersome positioning, etc., and achieve the effect of easy positioning, high precision, and guaranteed assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

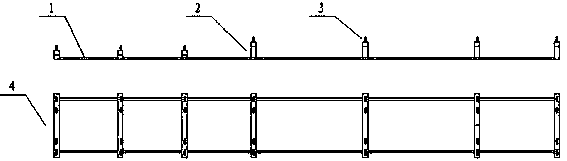

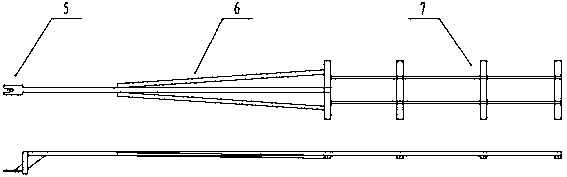

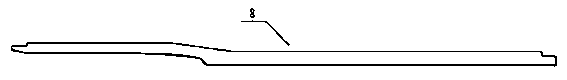

[0039] The combined tooling of this embodiment includes a bracket 10 and a positioning tool 12, the bracket 10 is placed below the longitudinal beam 9 of the semi-trailer frame, and the positioning tool 12 is placed above the longitudinal beam 9 of the semi-trailer frame.

[0040] Bracket 10 includes two connecting rods 1, 7 sets of vertical support rods 2 with different heights and 7 groups of horizontal cross bars 4 with different heights. Connected, the vertical support bar 2 and the horizontal cross bar 4 form a "Π" shape structure and fit together with the upper end surface of the longitudinal beam of the vehicle frame; the positioning blocks 3 for the positioning of the vehicle frame longitudinal beam are installed at both ends of the horizontal cross bar 4.

[0041] In order to facilitate processing and manufacturing, the vertical struts 2 of this embodiment are integrated with the connecting rods 1 and the horizontal bars 4 by welding. The connecting rod 1 is made of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com