Control unit of motor vehicle and method to operate motor vehicle

A technology for control devices and motor vehicles, applied in transmission control, mechanical equipment, vehicle parts, etc., can solve problems such as damage to switching elements, and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

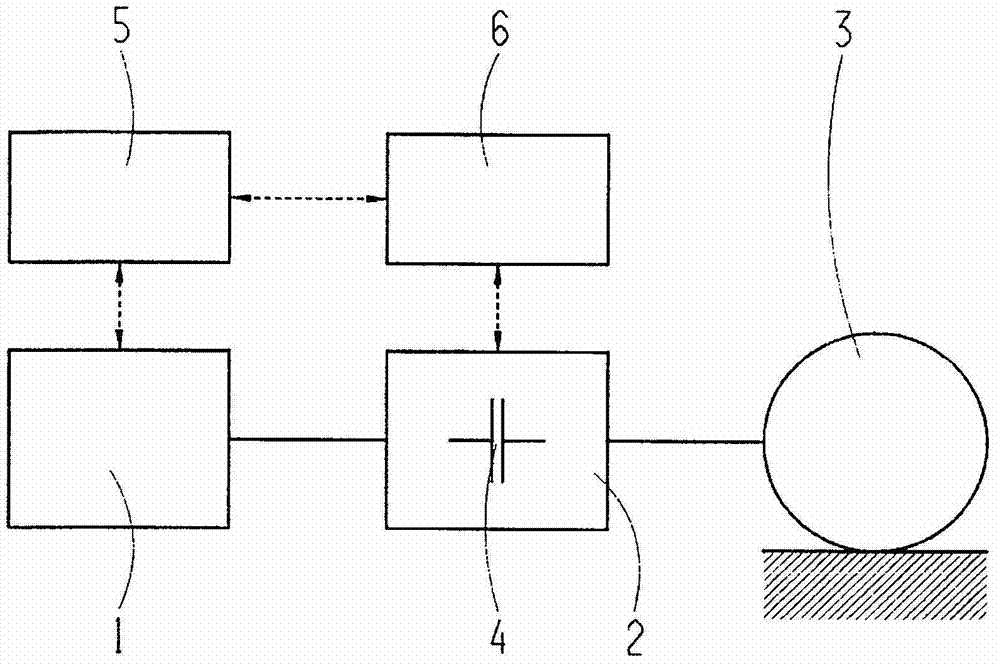

[0014] figure 1 A simplified diagram of the powertrain of a motor vehicle is shown schematically on a large scale. Therefore according to figure 1 The motor vehicle has a drive assembly 1 , a transmission 2 and a driven end 3 , wherein the transmission 2 is connected between the drive assembly 1 and the driven end 3 .

[0015] The transmission 2 comprises at least one form-fitting shifting element 4 , which can be realized, for example, as a pawl and has a drive-side component and an output-side component.

[0016] also figure 1 An engine control unit 5 for controlling and / or regulating the operation of the drive assembly 1 and a transmission control unit 6 for controlling and / or regulating the operation of the transmission 2 are shown. The engine control unit 5 exchanges data with the drive unit 1 in the direction of the double arrow. Likewise, the transmission control unit 6 exchanges data with the transmission 2 . Furthermore, data exchange takes place between the engi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com