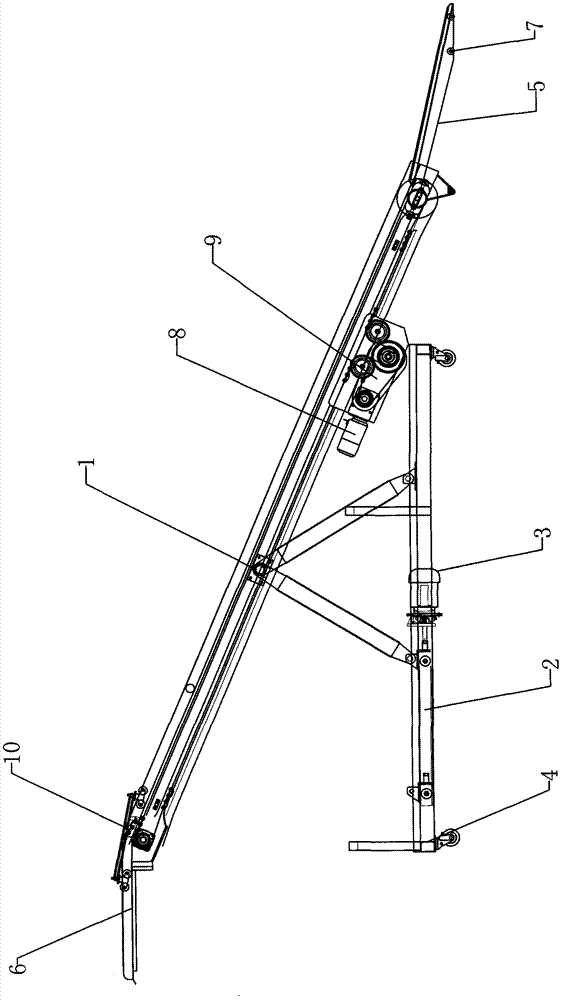

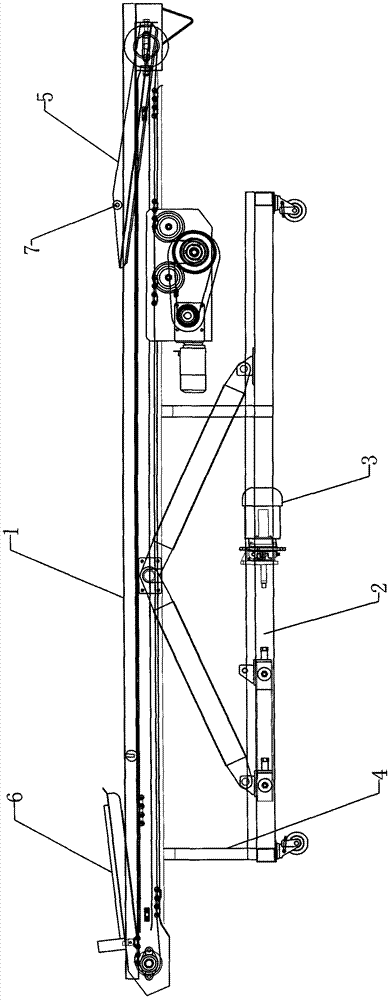

Seat conveyor and conveying method

A technology for conveyors and seats, applied in the field of seat conveyors and transportation, can solve the problems of low reuse rate of wooden pallets, waste of manpower and material resources, and high labor intensity, so as to save assembly time, save pallet costs, and reduce labor intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0031] XX company adopts the method of the present invention, and the reutilization rate of the wheel set is low. There are 40 seats in each carriage, and the calculation of 8 carriages in each row requires a wooden pallet fee of 32,000 yuan. The implementation of this technology is calculated on the basis of an annual output of 60 vehicles. Compared with the system, our company can save 3 million yuan a year internally; from dismantling and installing bolts to no need for 2 people to lift, saving more than 50% of labor, electric transmission, saving more than 20% of seat assembly time, and improving production capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com