A kind of asphalt water-based drilling fluid treatment agent and preparation method thereof

A water-based drilling fluid and treatment agent technology, which is applied in chemical instruments and methods, chemical processing of tar pitch/petroleum pitch/natural asphalt, earthwork drilling, etc. Poor filtration loss, difficult to meet the high temperature working environment requirements of deep wells and ultra-deep wells, etc., to achieve good anti-slump, low high temperature and high pressure filtration loss, and high oil-soluble content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the asphalt water-based drilling fluid treatment agent provided by the present invention, the recovery includes: distilling the neutralized qualified mixture, drying and pulverizing the obtained solidified product to obtain a high softening point asphalt water-based drilling fluid treatment agent, and distilling the obtained asphalt water-based drilling fluid treatment agent After the mixture of sulfonated dispersant and water is cooled, it is left to settle and stratified to obtain sulfonated dispersant and water respectively, and the sulfonated dispersant is used for recycling. During the distillation process, the distillation temperature is controlled not to exceed 150°C, preferably not to exceed 120°C.

[0022] In the method for using the drilling fluid treatment agent provided by the invention, the drilling fluid includes 1% to 3% by weight of the asphalt water-based drilling fluid treatment agent.

[0023] The drilling fluid treatment age...

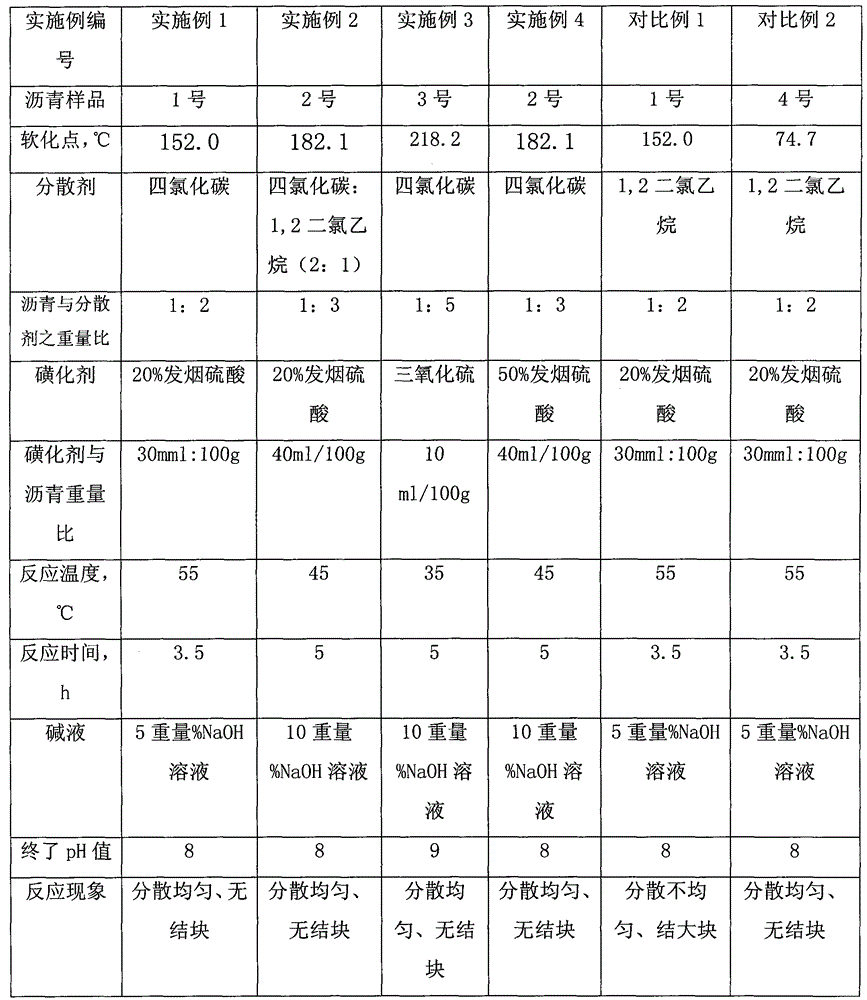

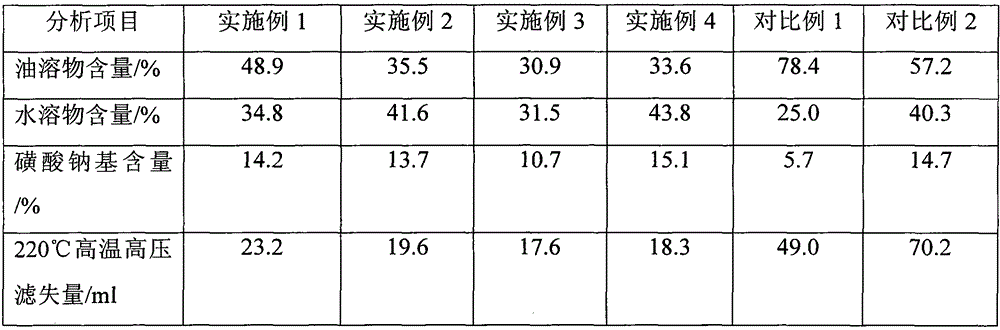

Embodiment 1

[0029] The properties of No. 1 asphalt used in this embodiment are shown in Table 1.

[0030] Take by weighing No. 1 bitumen sample 100g and pour in the 1000ml three-necked flask, add 200g carbon tetrachloride reagent (chemically pure) wherein, the three-necked flask is placed in the electric heating mantle, the mixture of pitch sample and dispersant is heated to a temperature of 40 DEG C, and stirred at a temperature of 40 DEG C for 10 minutes; by an isobaric burette, 20 ml of 20% oleum (sulfur trioxide content is 21.5% by weight) was added dropwise in the there-necked flask at a rate of 1 ml / min, after adding Stir at 40°C for 3.5h, and then slowly drop an aqueous sodium hydroxide solution with a concentration of 5% by weight into a three-necked flask through an isobaric burette to conduct asphalt sulfonic acid, unreacted sulfur trioxide and sulfuric acid generated by the reaction. Neutralization reaction, stop dripping sodium hydroxide solution when the pH value of reaction ...

Embodiment 2

[0032]According to the method of Example 1, the properties of No. 2 bitumen used in this example are shown in Table 1, and the sulfonated dispersant used is a mixed solution of carbon tetrachloride: ethylene dichloride (volume ratio 2: 1), and the used sulfonated agent is 50% oleum (sulfur trioxide content ≥ 50%). The operating conditions are shown in Table 2, and the product property analysis results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com