Coal chemical industry coke blending scheduling method for fine coal gasification adopting petroleum coke as raw material

A scheduling method and technology of petroleum coke, which is applied in the petroleum industry, granular/powdered fuel gasification, and the manufacture of combustible gas, etc., can solve the problems of inapplicability and achieve the effect of achieving similarity and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

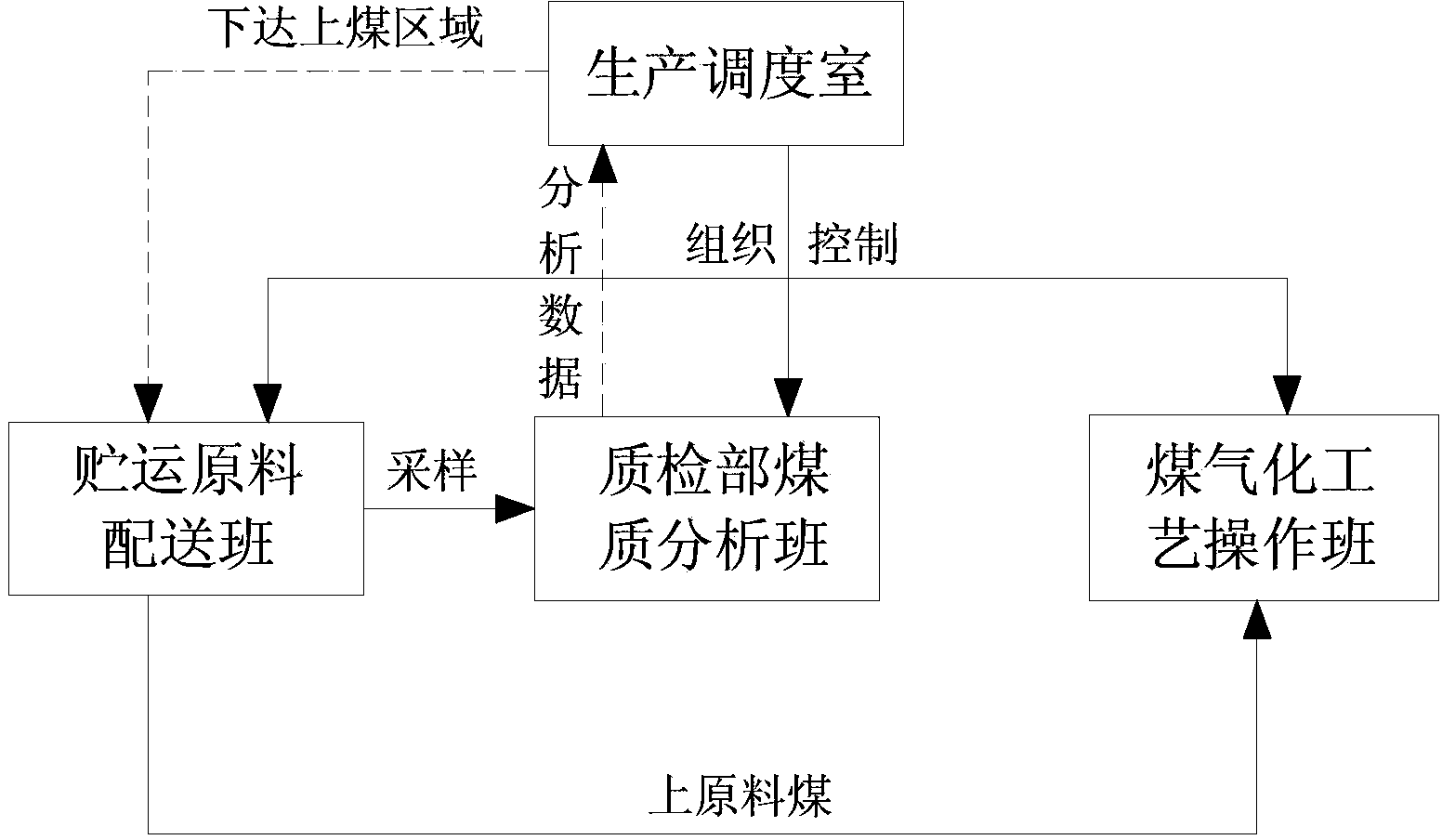

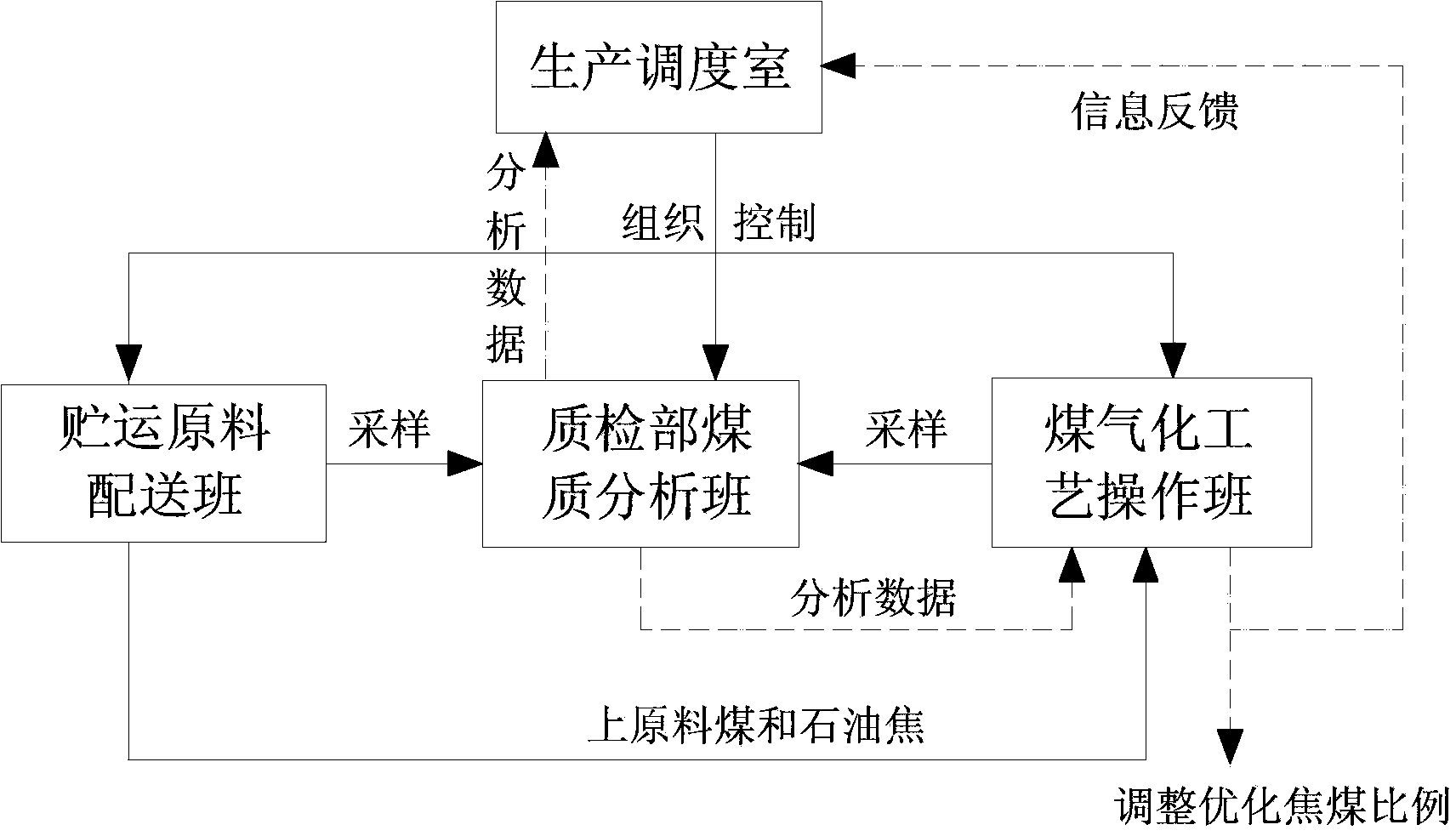

[0017] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

[0018] Such as figure 2 , a pulverized coal gasification coal chemical coke distribution scheduling method using petroleum coke as a raw material, which includes the following steps:

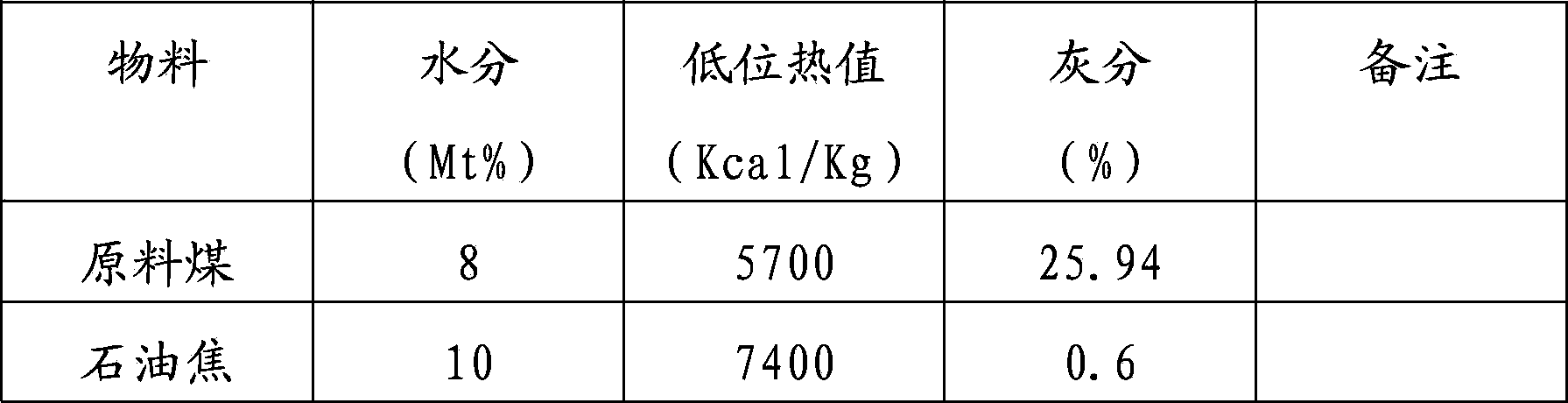

[0019] (1) The coal quality analysis team of the quality inspection department conducts sampling analysis on the raw coal and petroleum coke of the storage and transportation raw material distribution team, and obtains the analysis data of the actual ash content of the coke. The production dispatching room analyzes the coal quality of the quality inspection department Supervise the whole process of sampling, sample delivery and coal quality analysis of the raw coal and petroleum coke of the shift, such as manual sampling and review of suspicious coal, code compilation and decoding of all batches of coal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com