Aluminum reduction cell with plate-shaped diaphragm structure

A diaphragm structure and aluminum electrolytic cell technology, which is applied in the field of aluminum electrolytic cells, can solve the problems of reducing the current efficiency of aluminum electrolytic cells, excessive fluctuations in the interface of aluminum liquid, and increasing the occurrence of secondary reactions, so as to improve stability and reduce Interface fluctuations, reducing the effect of secondary reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

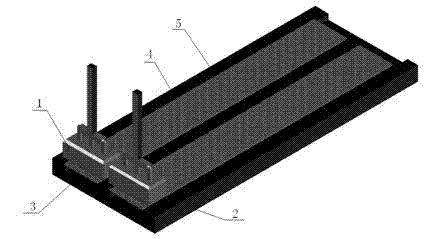

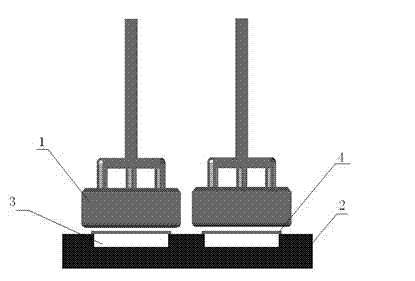

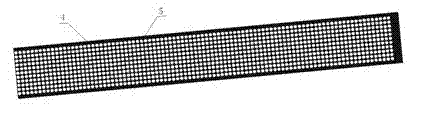

[0017] Embodiment of the present invention: adopt the aluminum electrolyzer with plate diaphragm structure, it comprises anode 1, cathode 2, is provided with diversion ditch 3 in cathode 2, is provided with plate diaphragm 4 above diversion ditch 3, Micropores 5 are provided on the plate-like separator 4 .

[0018] The shape of the micropore 5 is a cylindrical structure, or a truncated conical structure.

[0019] The cylindrical inner diameter of the microhole 5 is 50 mm.

[0020] The inner diameter of the frustum-shaped large round end of the microhole 5 is 80 millimeters.

[0021] The width of the plate-shaped diaphragm 4 is between the length of the guide groove 3 and the length of the anode 1 .

[0022] Such as figure 1 and figure 2 As shown, a diversion ditch 3 with a certain width and depth is processed on the cathode 2, and the upper part of the diversion ditch 3 is covered with a plate-shaped diaphragm 4 with micropores. The current can pass through the micropores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com