Double-slit saturated steam drafting device

A drafting device and double-slot technology, applied in the field of double-slot saturated steam drafting device, can solve the problems of poor tow quality affecting product strength indicators, discontinuous filaments, and many broken filaments.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

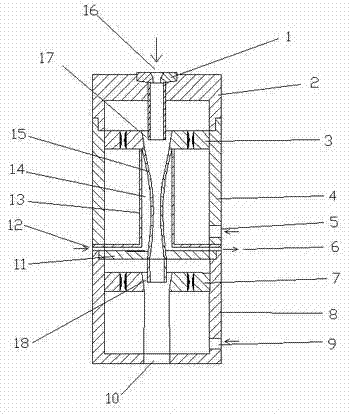

[0014] figure 1 A schematic structure of a double-slit saturated steam drafting device is shown. In the figure, the double-slit saturated steam drafting device includes a casing that is fixedly connected together by an upper cover 2, a middle shell 4 and a lower cover 8 in sequence, and an upper deflector 3 and a lower deflector 7 are arranged inside the casing. , a central curved wall tube 15 is fixedly connected to the bottom of the upper section deflector 3 central hole, the tube wall of the central curved wall tube 15 is provided with micropores through which a trace amount of saturated steam passes through the silk for instantaneous heating, and the central curved wall tube 15 The lower end extends into the central hole of the lower deflector 7, and the outer side of the curved wall pipe section of the central curved wall pipe 15 is formed by a heat insulating sleeve 13 to form a steam chamber 14, and a top with a tow inlet 16 is provided in the middle of the upper end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com