Light-transmitting soft film ceiling

A ceiling and soft film technology, applied in covering/lining, building, building structure, etc., can solve the problems that cannot meet the concept of craftsmen and affect the light transmission decoration effect of soft film ceilings, etc., achieve good visual effect and broaden the use range, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

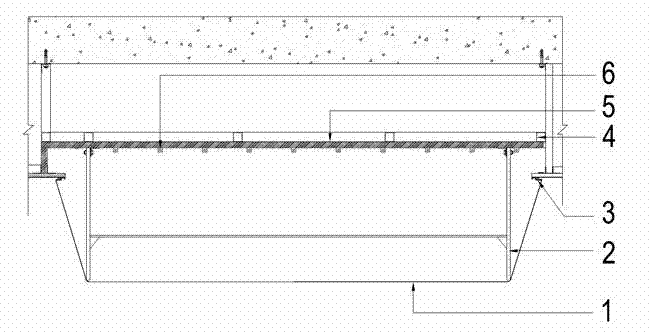

[0018] Example: such as figure 1 , figure 2 Shown is a light-transmitting soft film ceiling, which includes a light-transmitting soft film 1, an acrylic sheet 2, buckle edge strip keels 3, a skeleton 4, a flame-retardant board 5, and a light strip 6. The light strip 6 is an LED light strip.

[0019] The acrylic sheet 2 is used as the inner support frame of the light-transmitting soft film ceiling, and the light-transmitting soft film 1 covers the surface of the acrylic sheet 2 to form a curved shape. The flame retardant board 5 is fixed on the base frame 4 , the acrylic sheet 2 is fixed on the flame retardant board 5 , the light strip 6 is set on the flame retardant board 5 , and the edge of the light-transmitting soft film 1 is fixed on the buckle keel 3 .

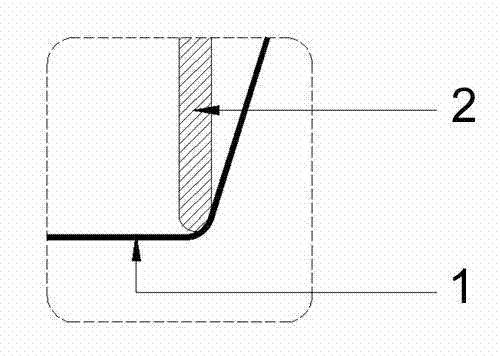

[0020] The thickness of the acrylic sheet 2 is 10 mm. Such as figure 2 As shown, the corners of the contact portion between the acrylic sheet 2 and the light-transmitting soft film 1 are rounded.

[0021] In terms ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com