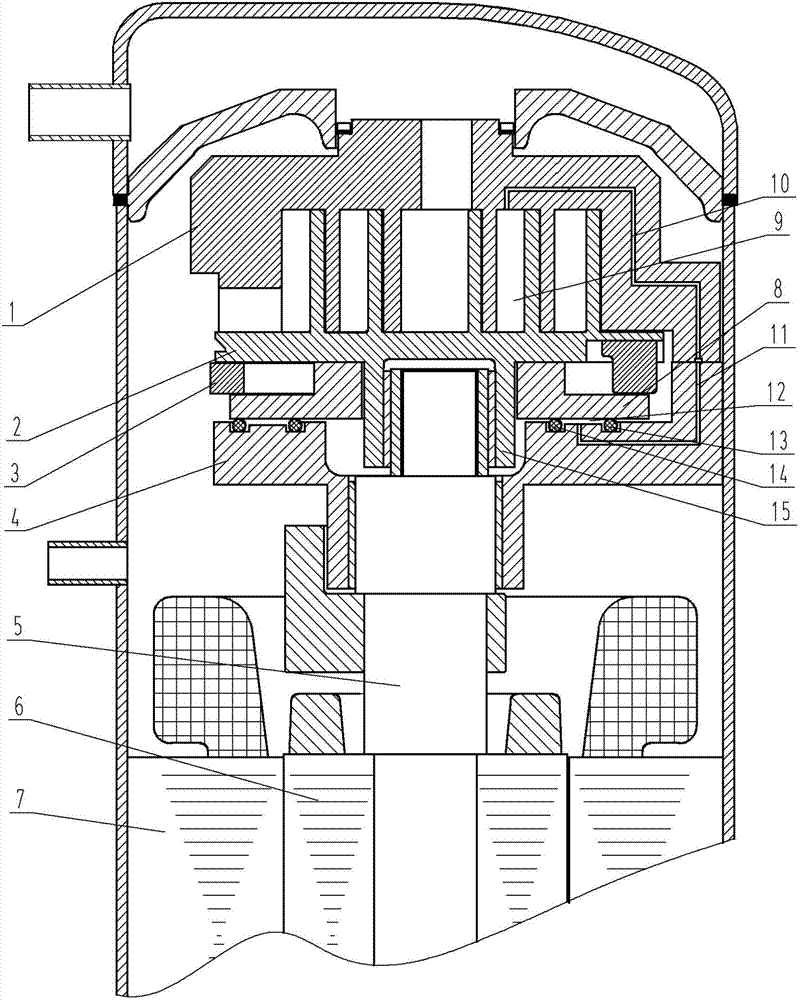

Floating scroll compressor

A scroll compressor and moving scroll technology, applied in the field of scroll compressors, can solve problems such as small space, tooth side leakage, and complex pressure chamber structure, and achieve the effect of large selection and simple structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

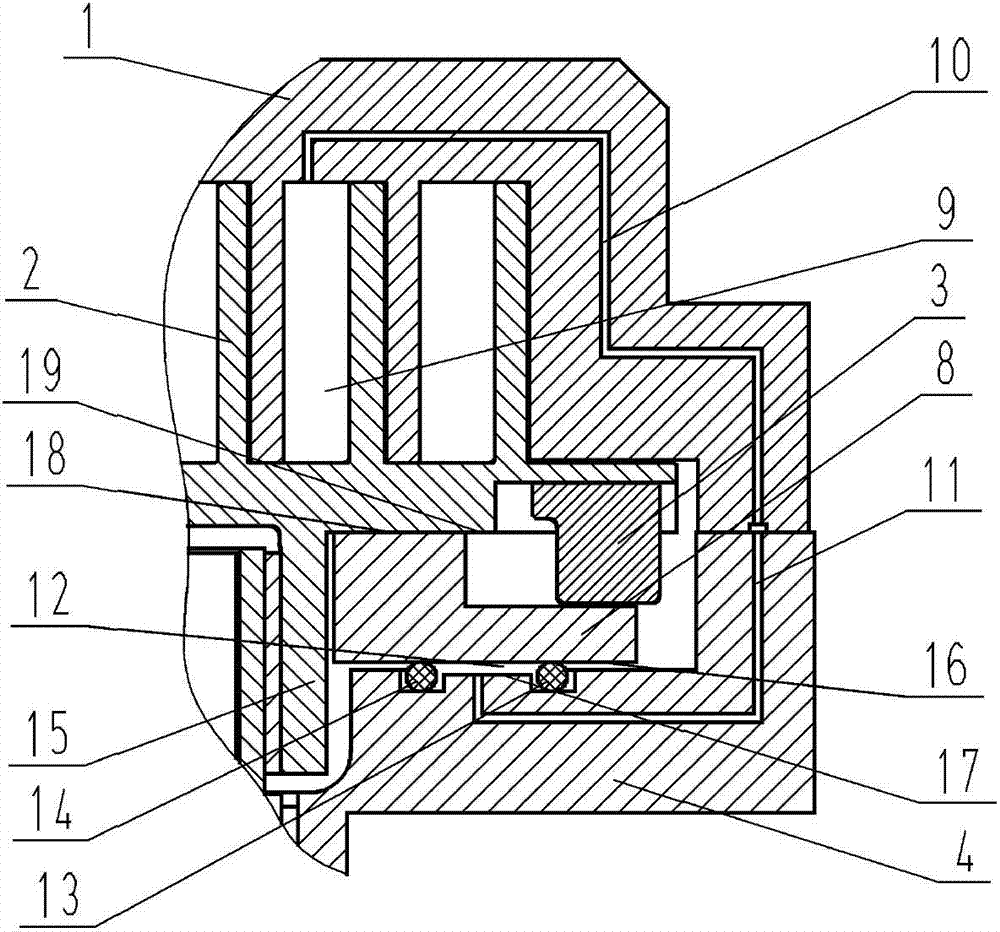

Embodiment 1

[0032] Such as figure 2As shown, a floating disc 8 is provided between the movable scroll 2 and the upper support 4, and the upper surface 17 of the upper support is provided with two annular grooves, and the seal A13 and the seal B14 are placed in the annular grooves, and the upper surface 17 of the upper support , the bottom surface of the floating plate 16, the seal A13 and the seal B14 form an annular pressure chamber A12, the pressure chamber A12 communicates with the upper support pressure introduction channel 11, and the other port of the upper support pressure introduction channel 11 is connected to the fixed scroll 1. The scroll pressure induction passage A10 communicates on the contact surface between the fixed scroll 1 and the upper support 4 , and the other port of the fixed scroll pressure introduction passage A10 communicates with the compression chamber 9 formed by the cooperation between the movable scroll 2 and the fixed scroll 1 .

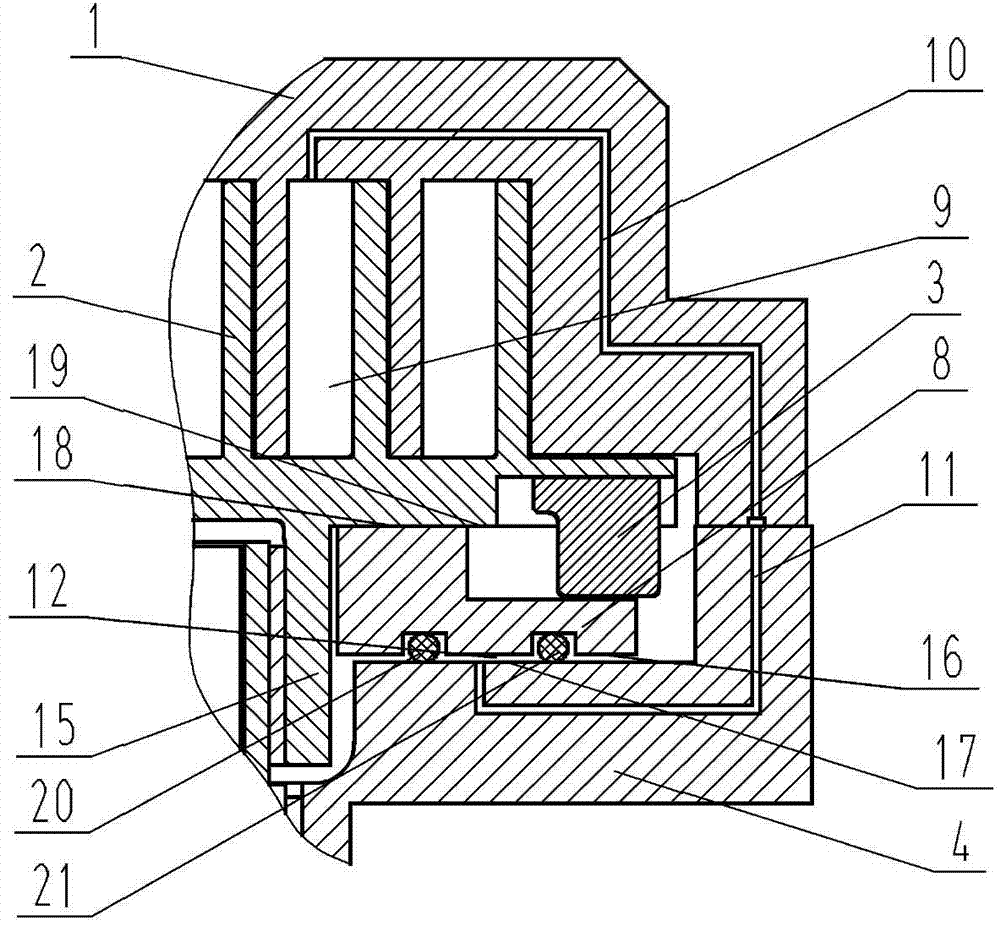

Embodiment 2

[0034] image 3 An embodiment of another sealing structure between the floating plate 8 and the upper support 4 is given, and its structure is as follows image 3 As shown: a floating disc 8 is provided between the movable scroll 2 and the upper support 4, and the bottom surface 16 of the floating disc is provided with two annular grooves, and the seal C20 and the seal D21 are placed in the annular grooves, and the upper surface of the upper support 17, An annular pressure chamber A12 is formed between the bottom surface 16 of the floating plate, the sealing member C20 and the sealing member D21.

Embodiment 3

[0036] Figure 4 An example of another opening form of the pressure introduction channel in the pressure chamber A12 is given, and its structure is as follows Figure 4 As shown: the pressure chamber A12 is connected to the upper support pressure introduction channel 11, and the other port of the upper support pressure introduction channel 11 and the fixed scroll pressure introduction channel B22 on the fixed scroll 1 are on the contact surface between the fixed scroll 1 and the upper support 4 The other port of the fixed scroll pressure guiding channel B22 communicates with the high pressure chamber 23 of the compressor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com