Locking releasing-preventive hexagon nut

A hexagonal nut and anti-dropping technology, applied in the direction of nuts, screws, bolts, etc., can solve the problems of difficulty in stabilizing the pre-tightening force, potential safety hazards, loosening, etc., and achieve the effect of improving connection strength, high safety performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

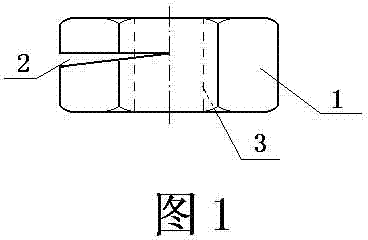

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] according to figure 1 As shown, the anti-loosening and anti-loosening hexagonal nut includes a hexagonal nut body 1 and a screw hole 3. The hexagonal nut body 1 is provided with a transverse wedge-shaped slot 2, and the depth of the wedge-shaped slot 2 reaches the depth of the screw hole 3. Center line; the angle of the wedge-shaped slot 2 is 3°.

[0014] In this embodiment, since the hexagonal nut body 1 is provided with a transverse wedge-shaped slot 2, the depth of the wedge-shaped slot reaches the center line of the screw hole 3. When the present invention is tightened with the bolt, the external force is used to hit this The position above the wedge-shaped slot 2 of the invention makes the gap of the wedge-shaped slot 2 smaller, and the local pitch of the nut changes, eliminating the gap between the thread pair of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com