Organic electroluminescence component and manufacturing method thereof

An electroluminescent element, organic technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, electric-solid-state devices, etc., can solve the problem of decreased dispersion stability of metal nanoparticles, poor film reflection characteristics or conductivity, metal reflective film Adhesion decline and other problems, to achieve the effect of suppressing the decline in luminous intensity, improving reflection characteristics, and improving reflection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

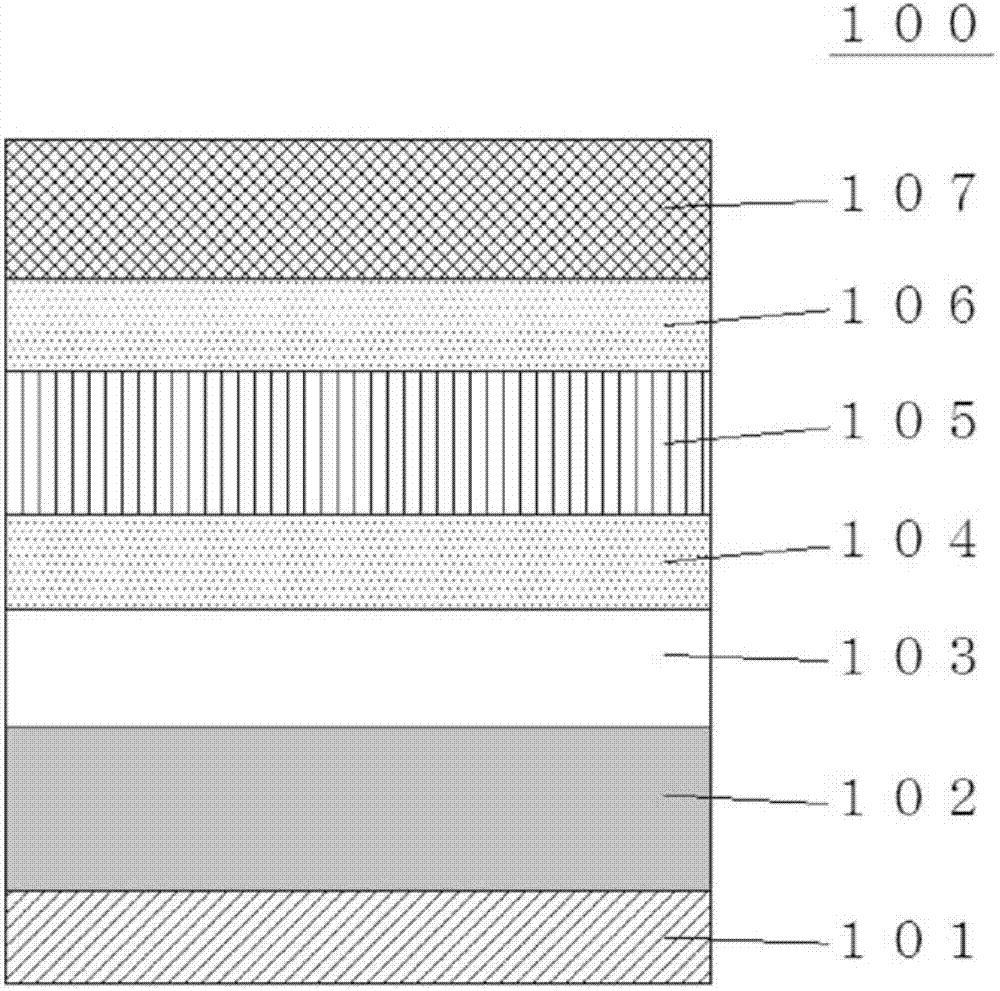

[0123] produced with figure 2 structure of organic EL elements. A metal reflective film with a film thickness of about 100 nm was formed by spin coating on a glass substrate at 1000 rpm for 60 seconds and firing at 200° C. for 30 minutes using the composition for a metal reflective film. The composition for a high-refractive-index enhanced-reflection transparent film was coated thereon by a spin coating method, and fired at 170° C. for 30 minutes to obtain an enhanced-reflection transparent film with a thickness of 25 nm. Then, an ITO transparent conductive layer (anode, thickness: 150 nm) was formed thereon by sputtering, followed by a hole transport layer (N,N'-diphenyl-N,N'-bis(m-tolyl)bi Aniline, thickness: 30nm), light-emitting layer (tris(8-quinolinolato)aluminum doped with 5% by weight of rubrene, thickness: 30nm) and electron transport layer (tris(8-quinolinolato)aluminum, thickness: 30nm). AlLi was further formed into a 5 nm film as a transparent electrode layer (...

Embodiment 2

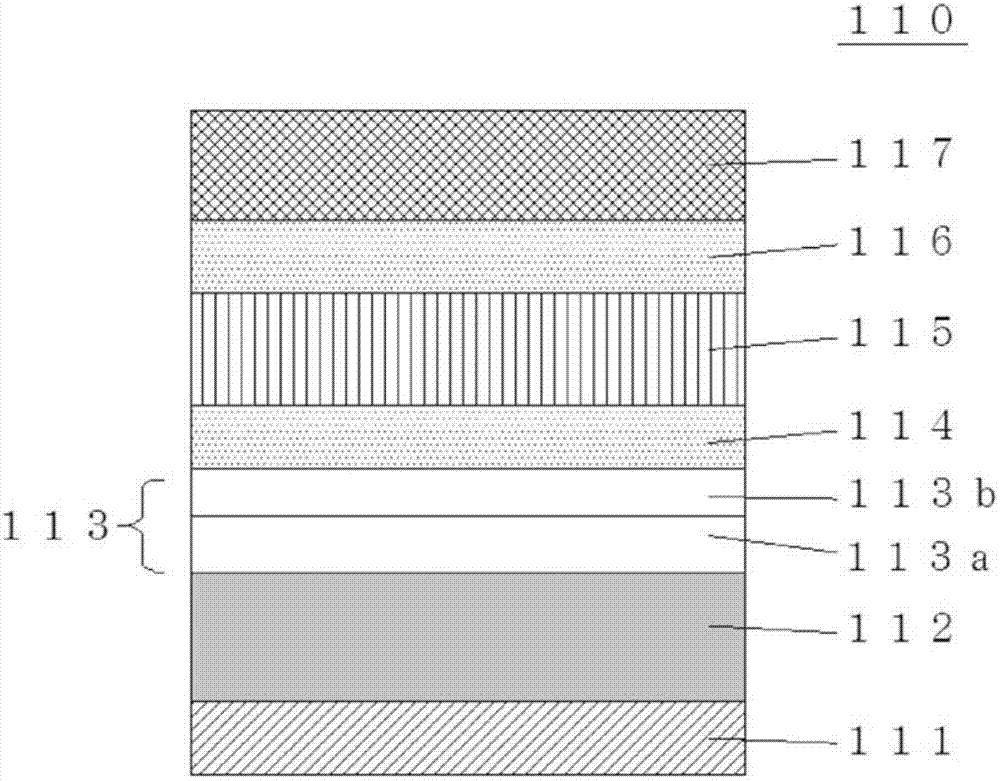

[0126] produced with image 3structure of organic EL elements. A metal reflective film with a film thickness of approximately 100 nm was formed by forming a film on a glass substrate at 1000 rpm x 60 seconds by spin coating and firing at 200°C for 30 minutes. . The composition for a low-refractive-index enhanced-reflection transparent film was coated thereon by a spin coating method, and fired at 170° C. for 30 minutes to obtain a low-refractive-index enhanced-reflection transparent film with a thickness of 25 nm. Except using the composition for a high-refractive-index enhanced-reflection transparent film, a 25-nm high-refractive-index enhanced-reflection transparent film was formed thereon in the same manner as the low-refractive-index enhanced-reflection transparent film. A transparent conductive layer of ITO (anode, thickness: 150 nm) was formed on it by sputtering, followed by a hole transport layer (N,N'-diphenyl-N,N'-bis(m-tolyl)benzidine, Thickness: 30nm), light-emi...

Embodiment 3~8

[0128] Except having formed the metal reflective film and the reflection-increased transparent film in the composition described in Table 1, it produced and evaluated similarly to Example 2. Here, ZrO 2 The average particle diameter of the particles is 30 nm, the average particle diameter of the ZnO particles is 20 nm, and the average particle diameter of the ITO particles is 25 nm. Table 1 shows the results.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap