Motive power battery box with balanced heat radiation structure

A heat dissipation structure and power battery technology, applied in structural parts, secondary batteries, battery pack parts, etc., can solve the problems of shortening the service life of the power supply system, uneven heat dissipation of the battery, uneven temperature, etc., and achieve simple structure and guaranteed High uniformity and heat dissipation consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

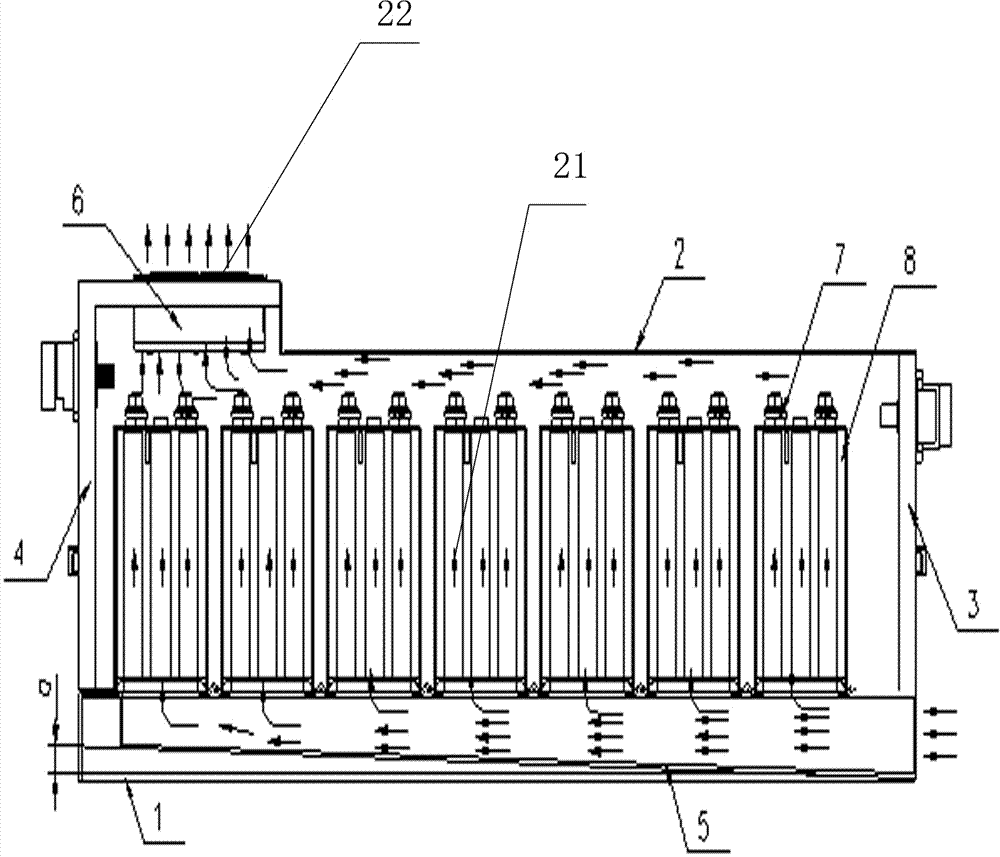

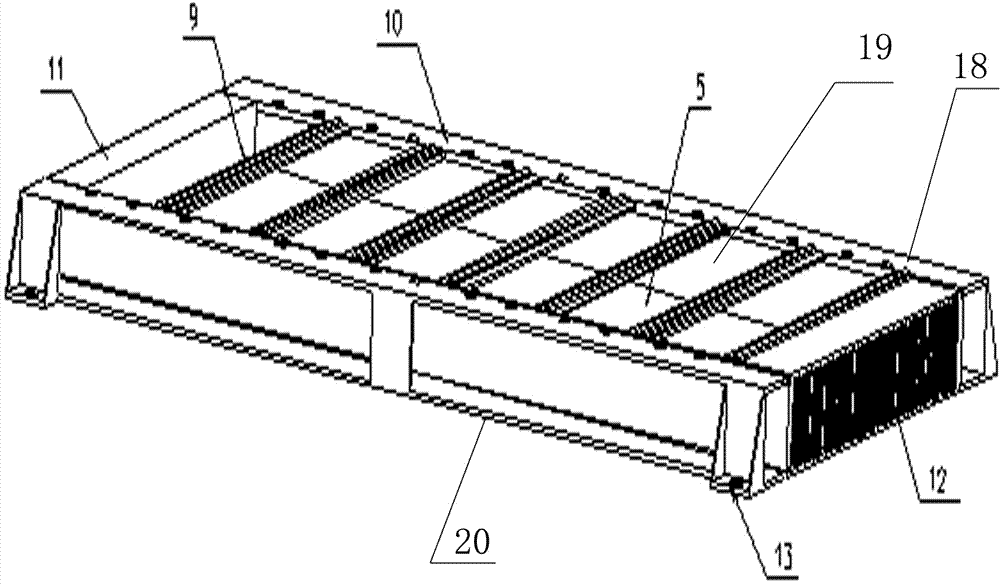

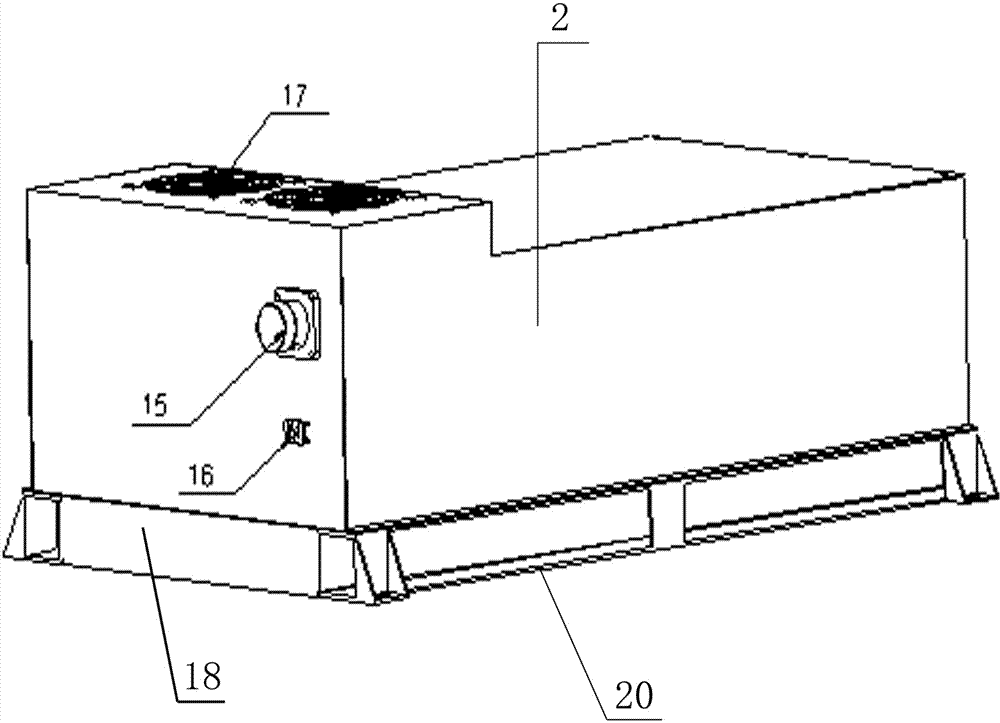

[0012] Embodiment one, in figure 1 and figure 2 Among them, the present invention provides a power battery box with a balanced heat dissipation structure, which mainly includes a chassis 1 and an outer cover 2. The chassis 1 is provided with a frame 18, and an air inlet plate 12 is provided at one end of the frame 18. The upper part of 18 is longitudinally arranged with seven connecting plates 9, gaps 19 are provided between the connecting plates 9, and an air deflector 5 is arranged in the frame 18, and the air deflecting plate 5 is located between the connecting plate 9 on the upper part of the frame 18 and the lower part of the frame 18. Between the base plates 20, the wind deflector 5 is inclined upwards and is provided with an angle between the upper part of the frame 18 to form an air guide groove. The upper part of the side is connected. After the wind deflector 5 is connected, there is an angle between the upper part of the frame 18. The two ends of the wind deflecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com