Method for treating lithium iron phosphate cathode material of waste and old power lithium battery of automobile

A technology for lithium iron phosphate and cathode material, which is applied in the field of processing waste lithium iron phosphate cathode materials for automotive power lithium batteries, can solve the problems of unfavorable industrial operation, large environmental pollution and high cost, and achieves high economic and social benefits, and is environmentally friendly. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

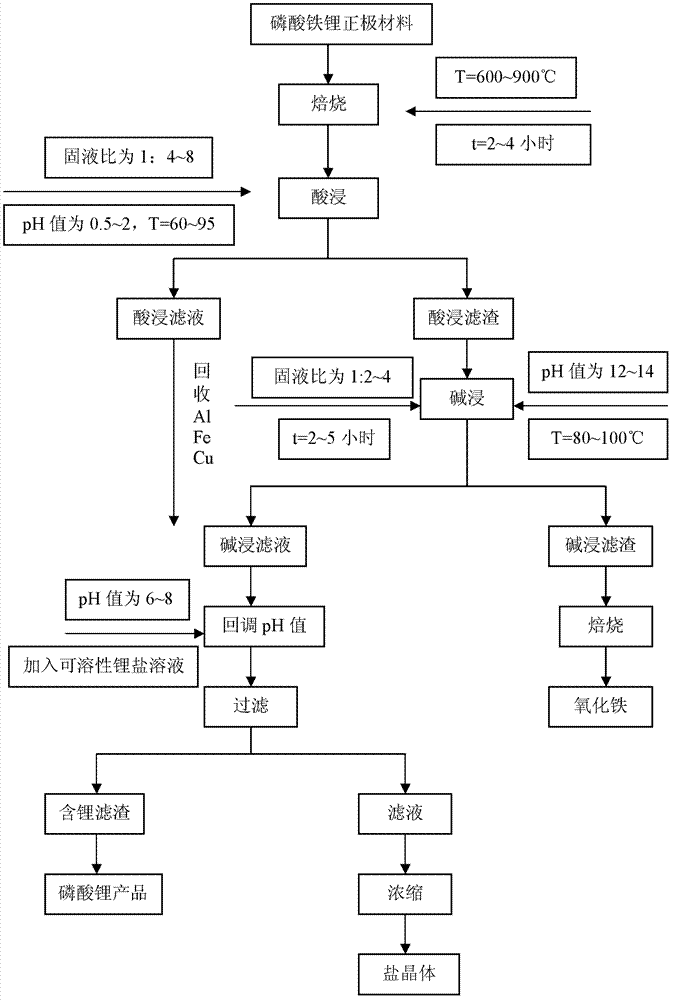

Image

Examples

Embodiment 1

[0025] A method for processing waste automobile power lithium battery lithium iron phosphate cathode material, comprising the following steps:

[0026] (1) Roasting: take the lithium iron phosphate cathode material and roast it at 600°C for 4 hours;

[0027] (2) Acid leaching: Put the roasted product into the acid solution according to the solid-to-liquid ratio of 1:4 for leaching, adjust the pH value of the acid solution to 0.5, and the acid leaching temperature at 60°C, filter and separate the solid and liquid, and collect the acid leaching filter residue and acid leaching filtrate;

[0028] (3) Alkali leaching: Take the acid leaching filter residue, put it into the lye for leaching for 2 hours according to the solid-liquid ratio of 1:2, adjust the pH value of the lye to 12, and the alkali leaching temperature to 80°C, filter and separate the solid and liquid, and collect them separately Alkali leaching filter residue and alkali leaching filtrate;

[0029] (4) Lithium reco...

Embodiment 2

[0032] A method for processing waste automobile power lithium battery lithium iron phosphate cathode material, comprising the following steps:

[0033] (1) Roasting: take the lithium iron phosphate positive electrode material and roast it at 900°C for 2 hours;

[0034] (2) Acid leaching: put the roasted product into the acid solution for leaching according to the solid-liquid ratio of 1:8, adjust the pH value of the acid solution to 2.0, and the acid leaching temperature is 95°C, filter and separate the solid and liquid, and collect the acid leaching filter residue and acid leaching filtrate;

[0035] (3) Alkali leaching: Take the acid leaching filter residue, put it into the lye for leaching for 5 hours according to the solid-liquid ratio of 1:4, adjust the pH value of the lye to 14, and the alkali leaching temperature to 100°C, filter and separate the solid and liquid, and collect them separately Alkali leaching filter residue and alkali leaching filtrate;

[0036] (4) Lit...

Embodiment 3

[0039] A method for processing waste automobile power lithium battery lithium iron phosphate cathode material, comprising the following steps:

[0040] (1) Roasting: take the lithium iron phosphate positive electrode material and roast it at 750°C for 3 hours;

[0041] (2) Acid leaching: Put the roasted product into the acid solution according to the solid-liquid ratio of 1:6 for leaching, adjust the pH value of the acid solution to 1.0, and the acid leaching temperature is 85°C, filter and separate the solid and liquid, and collect the acid leaching filter residue and acid leaching filtrate;

[0042] (3) Alkali leaching: Take the acid leaching filter residue, put it into the lye for leaching for 4 hours according to the solid-liquid ratio of 1:3, adjust the pH value of the lye to 13, and the alkali leaching temperature to 90°C, filter and separate the solid and liquid, and collect them separately Alkali leaching filter residue and alkali leaching filtrate;

[0043](4) Lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com