Resin rotational body and method for producing same

A rotating body and resin technology, applied to other household appliances, hoisting devices, mechanical equipment, etc., can solve the problems of cumbersome process and complex structure of forming molds, and achieve the effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

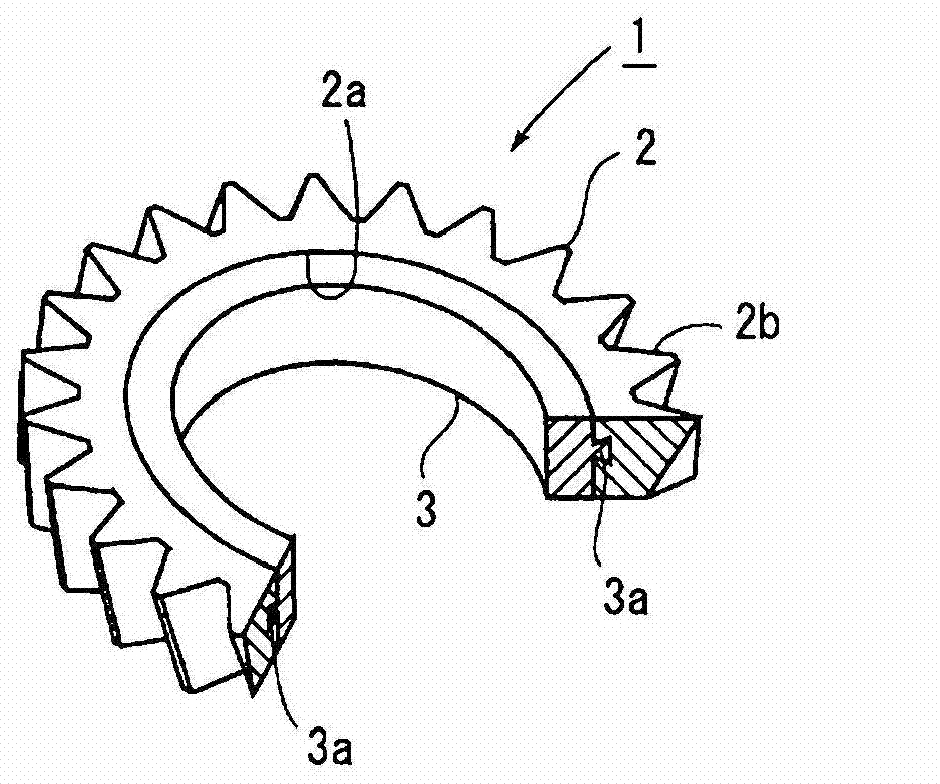

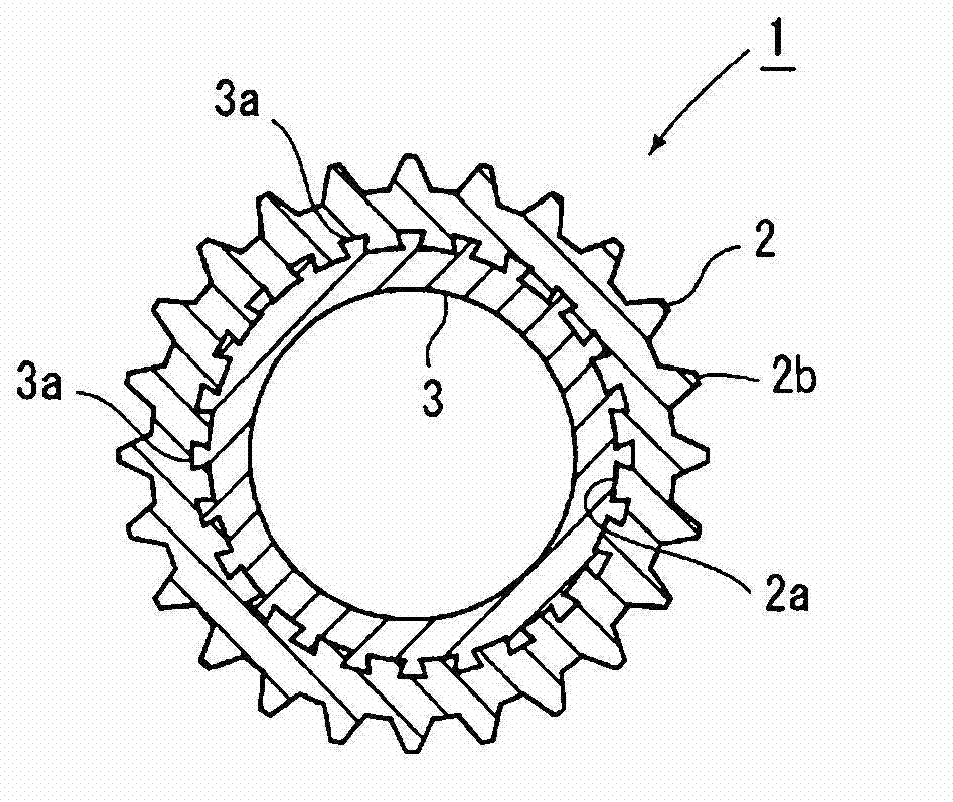

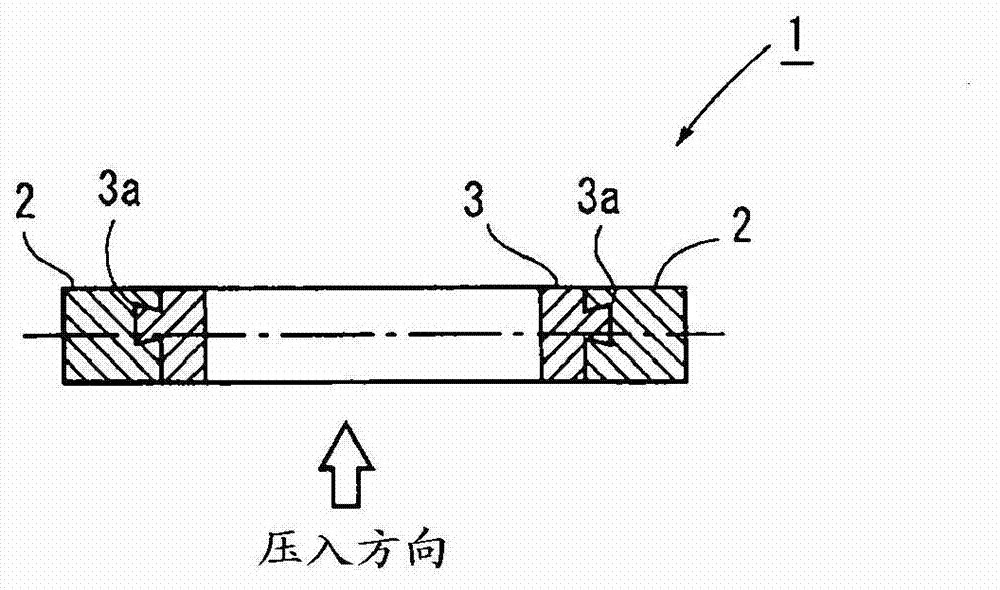

[0031] Hereinafter, the illustrated embodiment will be described, Figure 1 to Figure 3 Represents the resin rotating body 1 used for the balance shaft gear of the engine, etc., figure 1 is a perspective view of the resin rotating body 1, figure 2 is a circumferential cross-sectional view cut on a plane perpendicular to the central axis of the resin rotating body 1, image 3 It is an axial sectional view cut on a plane parallel to the axial direction.

[0032] The above-mentioned resin rotating body 1 is composed of an annular resin ring 2 and a metal bush 3 fitted on the inner peripheral surface 2a of the above-mentioned resin ring 2, and on the outer periphery of the above-mentioned resin ring 2, there are formed at equal intervals relative to the axial direction. The helical teeth 2b formed obliquely, the above-mentioned resin rotating body 1 constitute a helical gear.

[0033] The above-mentioned resin ring 2 is obtained by laminating a plurality of sheets of resin S i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com