Farmland irrigation machine

A technology of farmland and overall structure, applied in agriculture, watering device, horticulture, etc., can solve the problems of short infiltration time, unevenness, overlapping, etc., and achieve the effect of long infiltration time, uniform watering, and flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

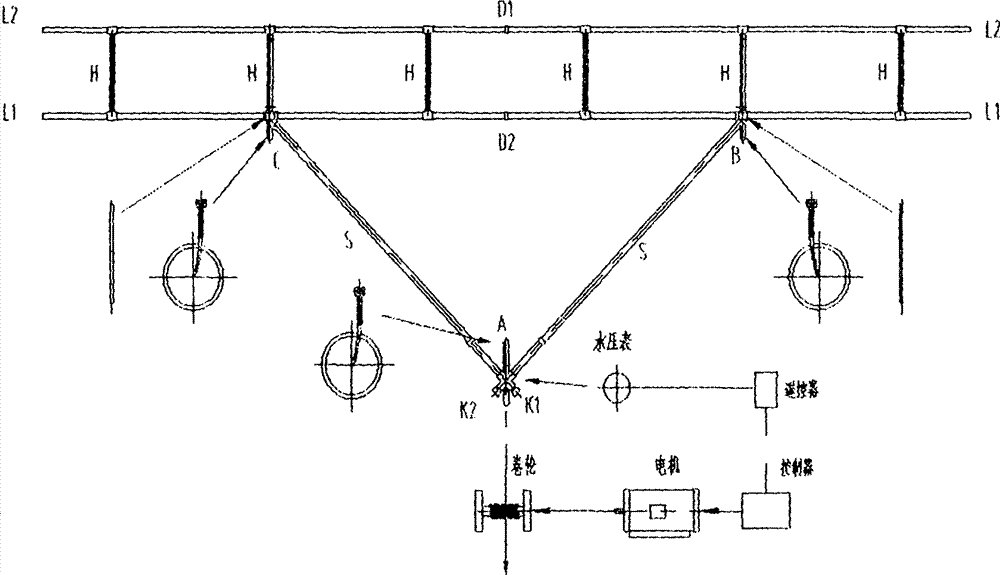

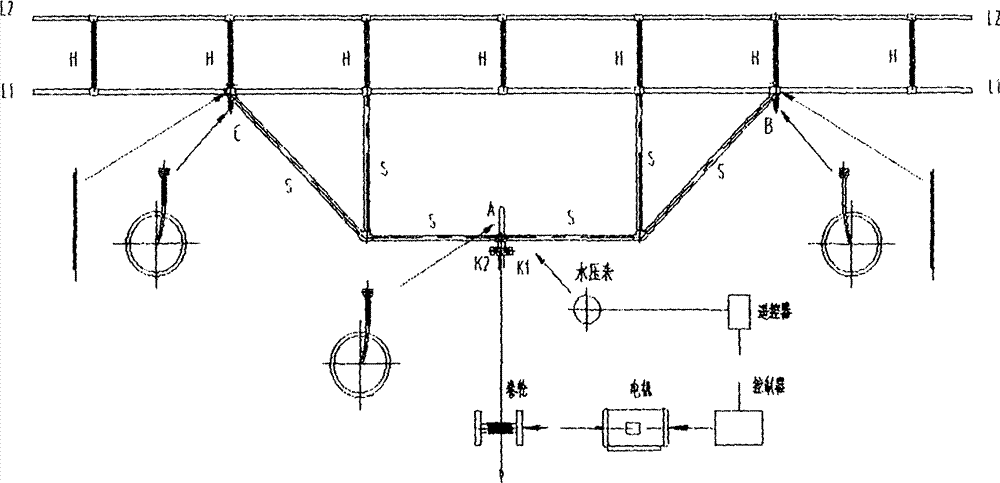

[0018] according to figure 1 It can be seen that the water source enters the planar overall structure from K1, enters the spraying horizontal pipe L1 through the diversion water delivery pipe S, sprays backward and downward through multiple rows of small holes, and then enters another spraying horizontal pipe through multiple short water delivery pipes H Pipe L2 again sprays downward and rearward. The water pipes S are arranged in a herringbone shape, the purpose of which is to stabilize the structure, and the main purpose is to divert the water and evenly enter the middle of both sides of the spraying horizontal pipe L1, so that the water flows evenly into the spraying horizontal pipe L1 and sprays backward and downward. The purpose of the pipe is to increase the front and rear spans of equipment spraying water during the process of slowly moving forward in the overall structure of the plane, thus increasing the water falling time at the same point on the ground to achieve th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com