Bottom die and die set link mechanism of bottle blowing machine

A technology of linkage linkage and rod mechanism, which is applied to other household appliances, household appliances, applications, etc., can solve the problems of bulky equipment, affect the working environment, and high cost investment, and achieve simple equipment structure, improve matching accuracy, and improve operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

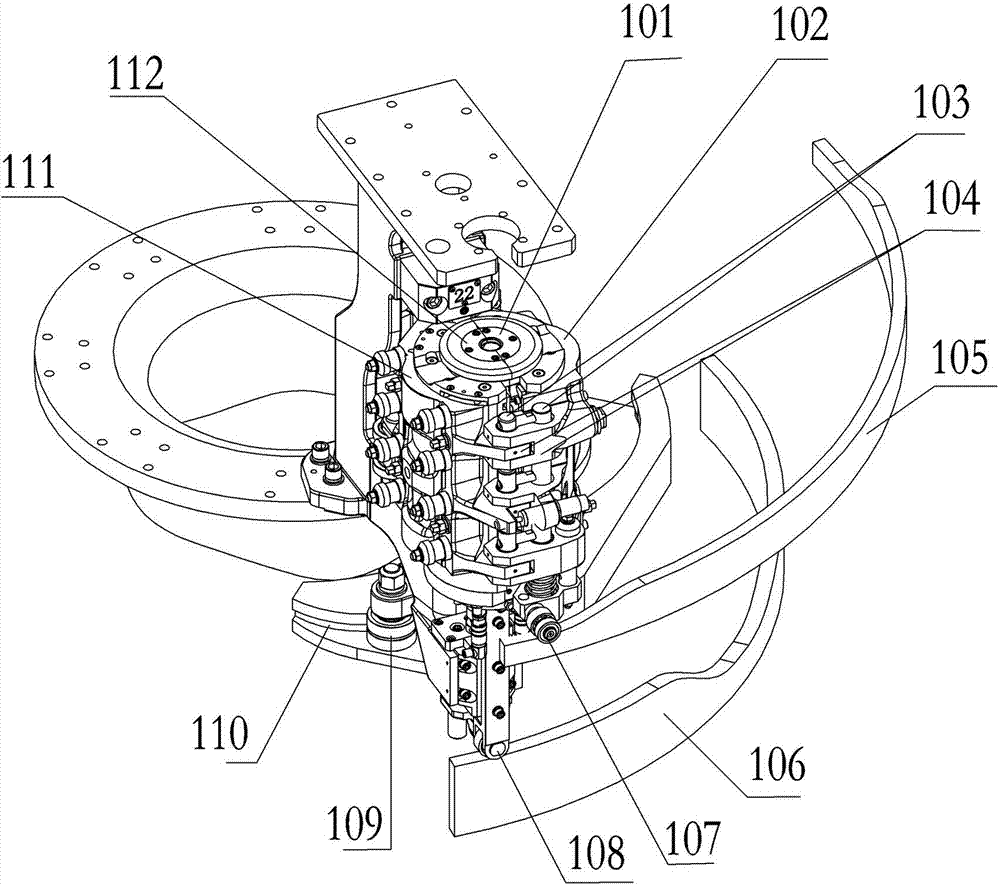

[0014] Embodiment one, such as Figure 4 to Figure 7 As shown, there is a bottom mold lifting roller 8 on the bottom mold lifting connecting rod 2; the slideway 4 with a height difference curve is located on the surface of the bottom mold lifting guide plate 3; the device for controlling the movement of the opening and closing mold connecting rod 1 is the opening and closing mold roller 7. The lifting device that drives the bottom mold is that the bottom mold lifting guide plate 3 is connected to the bottom mold lifting slide rail 5, and the bottom mold lifting bracket 6 is connected with the bottom mold lifting slide rail 5, so that the bottom mold lifting slide rail 5 drives the bottom mold Lifting bracket 6 lifts, and then drives bottom mold lifting; Bottom mold lifting slide rail 5 slides in slide rail seat 9, and slide rail seat 9 is arranged on the formwork support 10.

[0015] When the equipment is running, the mold opening and closing roller 7 on the opening and closin...

Embodiment 2

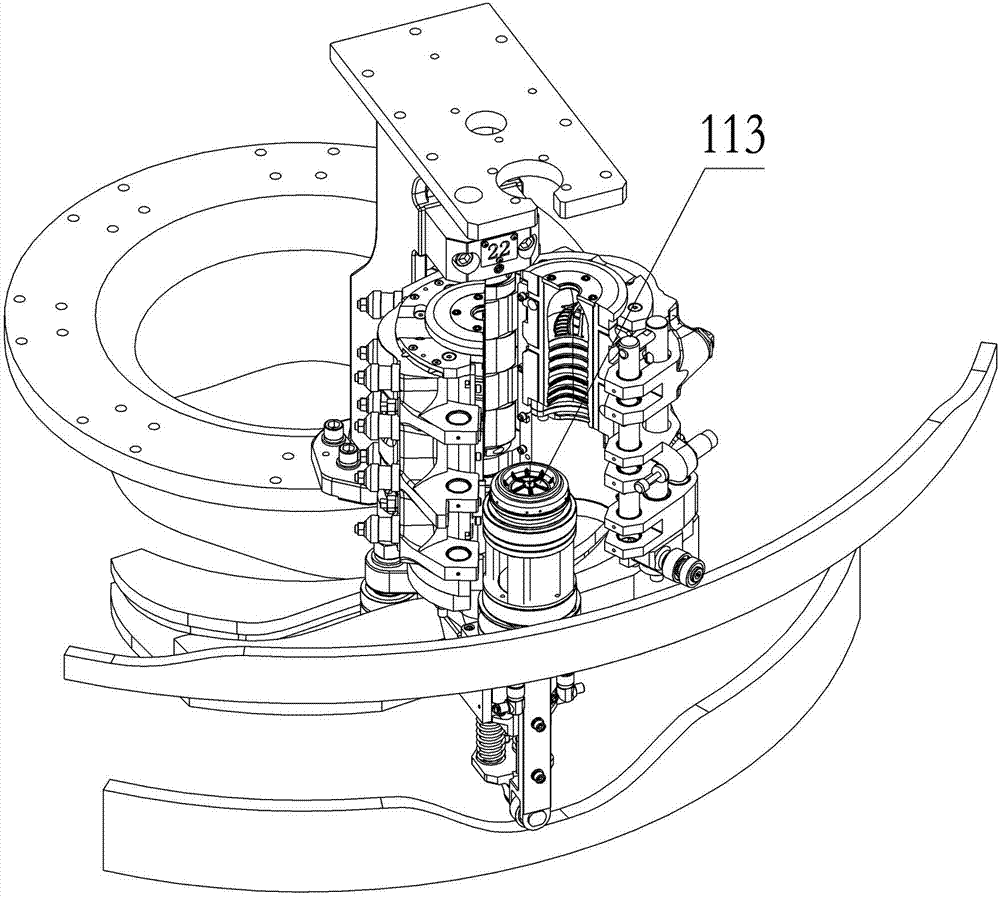

[0017] In the second embodiment, the structure and movement mode of the bottle blowing machine are similar to those in the first embodiment, the difference is that the lower edge of the lifting guide plate 3 of the bottom mold forms a slideway with a height difference curve. Bottom mold lifting roller 8 extends to the lower edge slideway of bottom mold lifting guide plate 3, and under the swing of opening and closing mold connecting rod 1, it drives bottom mold lifting connecting rod 2 to move on the lower edge of bottom mold lifting guide plate 3. After arriving at the predetermined position, the bottom mold will drop to the original position under its own gravity after the bottle blowing is completed.

Embodiment 3

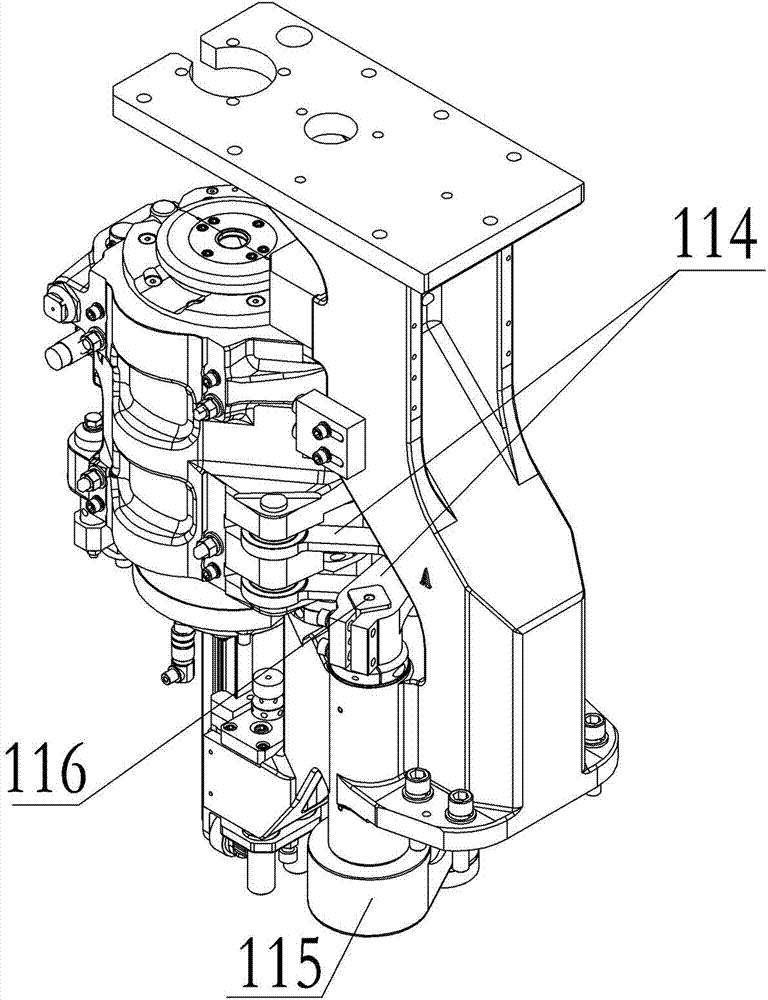

[0018] Embodiment 3, the structure and movement mode of the bottle blowing machine are similar to Embodiment 1, the difference is that the driving device for controlling the swing of the mold opening and closing rod 1 is a stepping motor. A stepping motor is installed on the opening and closing mold connecting rod 1, and the stepping motor drives the opening and closing mold connecting rod 1 to swing, thereby realizing the linkage of the opening and closing of the mold frame and the lifting of the bottom mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com